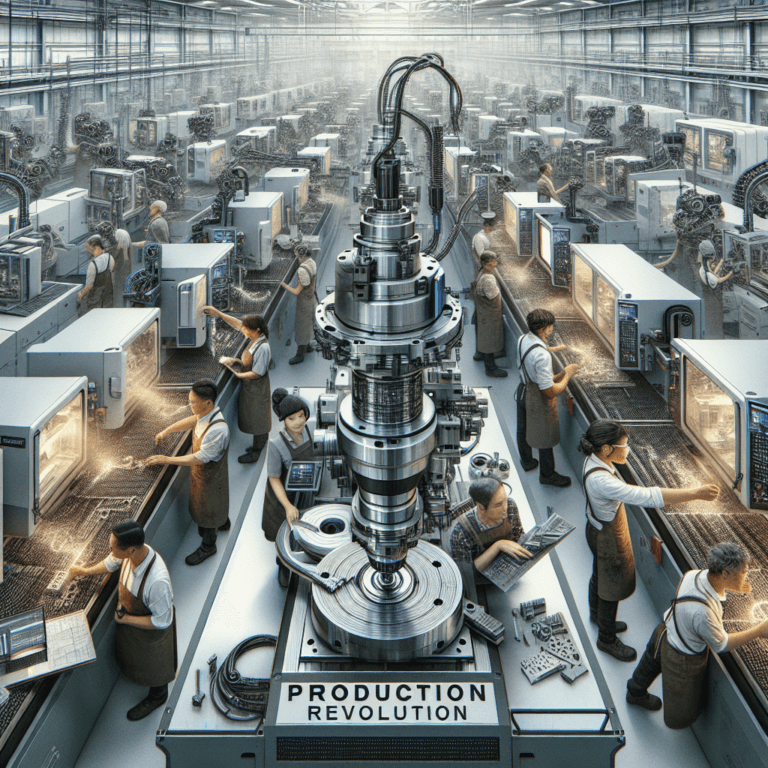

In today’s fast-paced manufacturing environment, CNC (computer numerical control) machining has become a key technology that is changing the way we think about production processes. This blog goes deep into the heart of a CNC machining plant, exploring innovative technologies that increase efficiency and precision, as well as the scientific principles that underpin this advanced manufacturing paradigm. From improved workflows to the implementation of state-of-the-art machinery, learn how CNC machining is revolutionizing production as we know it.

What is CNC machining?

CNC machining is a process in which computer-controlled machines use a variety of tools to perform precise machining operations. This technology paves the way for manufacturers to achieve unparalleled precision and efficiency. Unlike traditional machining methods that rely heavily on manual labor, CNC machining automates the cutting process, reducing human error and minimizing waste.

The basic components of CNC machining include:

Computer Aided Design (CAD): This software allows engineers to create complex designs that can be easily translated into machine language.

Computer Aided Manufacturing (CAM): CAM software converts CAD designs into a format that CNC machine tools can understand, providing the instructions required for operation.

CNC machine tools: These machines include lathes, milling machines, and milling machines that perform cutting and shaping of materials according to commands from CAM software.

- feedback system: The integration of sensors and real-time monitoring systems ensures continued accuracy and quality throughout the machining process.

Together, these elements create an integrated and streamlined production process that minimizes errors and maximizes output quality.

CNC machining factory workflow

Step 1: Design and Prototyping

The journey begins in the design phase, when engineers and designers use CAD software to create detailed models of the required parts. The model contains all specifications, including dimensions, tolerances, and material types. At this stage, simulation enables visualization of the machining process, helping to predict and mitigate potential problems before actual production begins.

Step 2: Programming

Once the design is finalized, it is converted into machine code using CAM software. This programming step is crucial because it determines the precise operations that the CNC machine will perform. Factors such as feed rates, cutting speeds and tool paths are carefully calibrated to ensure optimal machining efficiency.

Step 3: Setup

Before starting the machining process, the machine needs to be set up correctly. This includes:

Tool selection: Selecting the right cutting tool based on material and design specifications is critical to achieving the required surface finish and precision.

Material loading: Raw materials (usually blocks or sheets) must be securely mounted on the machine bed to prevent movement during processing.

- calibration: Machines are calibrated to specific settings, ensuring every aspect of the process is optimized for improved accuracy.

Step 4: Machining Process

Once programming and setup are complete, production can begin. CNC machines cut, shape and finish materials according to programmed instructions. The entire process is automated, and the machine performs high-speed continuous operations, resulting in a uniform product with exceptional precision.

Step 5: Quality Control

As parts are machined, they undergo rigorous quality control inspections to ensure they meet design specifications. Technologies such as coordinate measuring machines (CMM) and laser scanning can be used to check dimensions and surface quality. This continuous feedback loop helps catch errors early in the manufacturing process.

Step 6: Finishing and Assembly

After passing quality inspection, parts may undergo additional finishing processes such as polishing, anodizing or painting based on customer requirements. Once the final touches are completed, the parts can be assembled into the final product, ready for distribution.

Innovations Shaping CNC Machining

The world of CNC machining is constantly evolving, influenced by developments in technology and manufacturing trends. Here are some of the groundbreaking innovations that are reshaping the industry:

1.Advanced materials

The introduction of new materials such as carbon composites and advanced alloys has expanded CNC machining capabilities. These materials have an excellent strength-to-weight ratio and can withstand extreme conditions, making them ideal for industries such as aerospace and automotive.

2. Additive manufacturing integration

Combining CNC machining with additive manufacturing (3D printing) enables hybrid production processes that leverage the strengths of both technologies. For example, parts can be printed and then precisely machined to achieve tighter tolerances or minor features.

3. Artificial Intelligence and Machine Learning

Artificial intelligence and machine learning applications are increasingly being used to enhance CNC machining operations. Predictive maintenance systems can analyze machine performance data to predict potential failures, minimizing downtime. Additionally, adaptive machining technology allows machines to adjust cutting parameters in real time based on feedback from the production process.

4. Industry 4.0 and the Internet of Things

The emergence of Industry 4.0 interconnects CNC machine tools with the Internet of Things (IoT), facilitating real-time monitoring and data exchange. This connectivity can enhance automation, allowing factories to operate with unprecedented efficiency.

5. Robotics and Automation

Robotic arms are now frequently used in CNC machining environments to perform tasks such as loading and unloading parts, applying cutting fluid, and performing secondary operations. Increased automation not only increases productivity but also reduces labor costs.

The environmental impact of CNC machining

While CNC machining offers numerous economic benefits, its environmental impact is an important consideration in today’s production environment. CNC machining plants are taking several initiatives to minimize their ecological footprint:

1. Sustainable materials

Switching to sustainable materials is crucial to reducing waste. Biodegradable composites and recycled metals are growing in popularity, promoting a circular economy in manufacturing.

2. Waste reduction technologies

Efforts to reduce waste include optimizing tool paths to minimize material scrap and implementing recycling programs for metal shavings and by-products. Additionally, CNC machines equipped with advanced filtration systems help capture and recycle cutting fluids.

3. Energy efficiency

Energy-efficient CNC machines and systems help reduce energy consumption. Manufacturers are increasingly using variable frequency drives (VFDs) to control motor speed, thereby reducing unnecessary energy consumption during operation.

in conclusion

CNC machining is undoubtedly revolutionizing production processes in industries ranging from automotive to aerospace. By integrating advanced technologies and adhering to sustainable practices, CNC machining plants not only produce high-quality parts with unparalleled precision, but also lay the foundation for a more efficient and responsible manufacturing future. As we further explore the world of CNC machining, it’s clear that innovation will continue to shape the trajectory of production, driving continuous improvement and expanding possibilities.

FAQ

1. What are the main advantages of CNC machining?

CNC machining offers several benefits, including improved accuracy, increased efficiency, reduced human error, and the ability to produce complex geometries. Additionally, it ensures consistent quality across multiple parts, ultimately reducing production costs.

2. Which industries use CNC processing?

CNC machining is widely used in various industries, including aerospace, automotive, medical device, consumer electronics and industrial machinery manufacturing.

3. How to choose the right CNC machining service?

Consider factors such as the service provider’s experience, technical capabilities, material supply and quality control measures. It is also important to evaluate their ability to meet your specific design requirements and production volumes.

4. What materials can be processed with CNC technology?

CNC machining can process a variety of materials, including metals (aluminum, steel, titanium), plastics, wood, and composites. Material selection often depends on the strength, precision and application required of the finished part.

5. How does CNC machining compare with traditional machining methods?

CNC machining typically offers greater accuracy, repeatability, and efficiency than traditional machining methods. CNC machines can automate complex tasks and execute complex designs with minimal manual intervention, thereby shortening production time and reducing labor costs.

By understanding the capabilities and innovations of CNC machining, manufacturers and consumers alike can appreciate the significant advancements this technology brings to the production world.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.