introduce

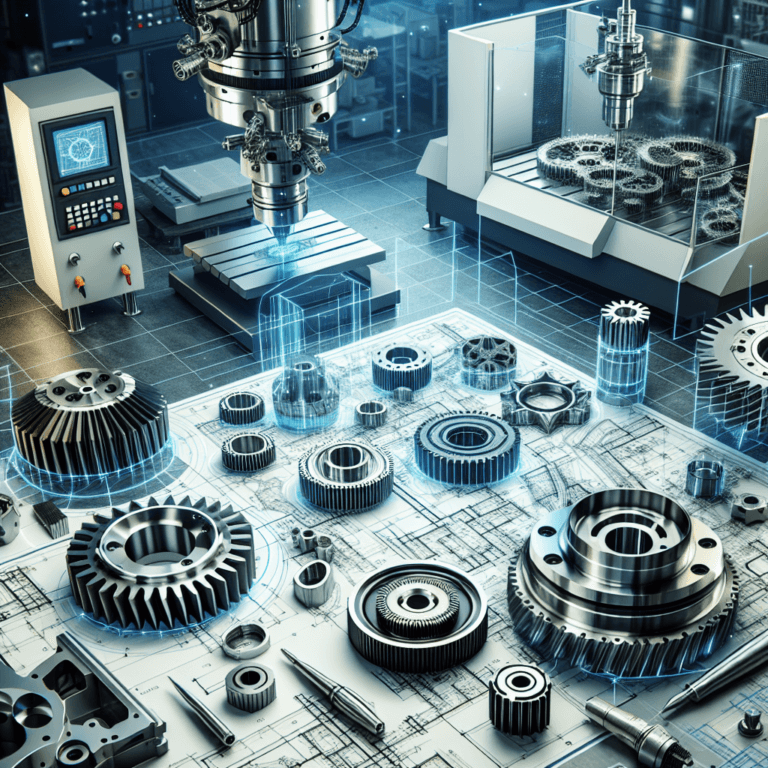

Computer Numerical Control (CNC) custom machining represents a groundbreaking leap in modern manufacturing, blending advanced technology with unrivaled precision. This sophisticated process allows manufacturers to create intricate designs and intricate geometries with exceptional accuracy and repeatability. In an era where efficiency, customization and quality are paramount, the adoption of CNC machining has revolutionized industries from aerospace to automotive, medical devices to electronics. This article takes an in-depth look at the many benefits of CNC custom machining, highlighting its importance and transformative impact.

1. What is CNC custom processing?

CNC custom machining involves the use of computer controls to operate machine tools, facilitating the precise cutting, shaping and finishing of materials such as metals, plastics and composites. Unlike traditional machining methods that rely on manual input, CNC machining utilizes algorithms and CAD (computer-aided design) files to control tool movement, resulting in a highly automated and efficient production process.

1.1 CNC machining process

The CNC machining process consists of several key stages:

design creation: Engineers or designers use CAD software to create digital models. This step is crucial because the accuracy of the design directly affects the quality of the final product.

Tool path generation: CAM (computer-aided manufacturing) software converts CAD designs into tool paths that determine how CNC machines move and machine materials.

set up: A CNC machine tool is equipped with the necessary tools (such as a drill, lathe, or mill) and the workpiece is securely held in place.

processing: CNC machine tools start the machining process according to programmed instructions and perform tasks such as cutting, drilling or grinding.

- finishing: After the machining process, additional finishing steps including polishing, coating, or assembly may be applied to obtain the desired final product.

2. Main advantages of CNC custom machining

As the industry develops, CNC custom machining has become the cornerstone of modern manufacturing due to its many advantages. Below, we explore the key benefits that make CNC machining an indispensable asset to your business.

2.1 Precision and accuracy

CNC custom machining is synonymous with precision. The technology allows for tight tolerances (usually within thousandths of an inch), ensuring parts fit together seamlessly. This level of accuracy is critical to an industry where even small deviations can lead to catastrophic failure or costly rework.

2.2 Consistency and repeatability

Once a CNC program is established, parts can be produced in large quantities without sacrificing quality. This consistency is especially important for mass production, which requires hundreds or thousands of identical components. CNC machines deliver consistent results, minimizing variation and errors.

2.3 Cost-effectiveness

While the initial investment in CNC technology can be significant, the long-term cost savings are also significant. CNC machining reduces the need for manual intervention, thereby lowering labor costs. In addition, fast production capabilities mean shorter delivery times, allowing companies to respond quickly to market demand.

2.4 Material versatility

CNC custom machining can accommodate a variety of materials, including metals (such as aluminum, steel, and titanium), plastics (such as PVC and polycarbonate), and composites (including carbon fiber and fiberglass). This versatility allows manufacturers to meet the needs of a variety of applications and industries.

2.5 Design flexibility

The programmable nature of CNC machining provides unparalleled design flexibility. Unlike traditional machining methods that may be limited by tool geometry or manual capabilities, CNC machines can produce complex geometries and intricate designs that were previously unachievable. This enables engineers to innovate and create custom solutions suited to specific requirements.

2.6 Automated production

CNC custom machining enhances manufacturing automation. The machine can run continuously without interruption, thereby increasing productivity. They can be programmed to perform multiple operations, reducing the number of machines required and freeing up people to perform other tasks.

2.7 Enhance security

CNC machine tools are designed with safety in mind. Automation of the machining process minimizes human interaction with potentially hazardous rotating tools and materials. In addition, many modern CNC machine tools are equipped with safety devices such as guards and emergency stop buttons to protect personnel from accidents.

2.8 Advanced technology integration

CNC custom machining can be seamlessly integrated with other technological advancements, such as IoT (Internet of Things) devices and AI (artificial intelligence). This capability allows the development of smart manufacturing processes where machines communicate with each other and optimize production in real time based on data analysis and predictive modeling.

3. Industries that benefit from CNC custom processing

CNC custom machining is not limited to a single field; instead, its applications span multiple industries. Below, we explore how various fields are leveraging this technology.

3.1 Aerospace industry

The aerospace industry demands the highest precision and reliability from its components. CNC machining plays a vital role in the manufacturing of complex parts such as turbine blades, landing gear and fuselage components. CNC machining’s ability to produce lightweight, high-strength parts that meet strict regulatory requirements makes CNC machining indispensable in this field.

3.2. Automobile industry

CNC custom machining is widely used in the automotive industry to manufacture complex engine components, transmission components, and other critical components. With the development of electric vehicles and autonomous driving technology, the demand for customized parts has skyrocketed, and CNC machining is well-positioned to meet these changing needs.

3.3 Medical devices

The medical field relies on CNC machining to produce precision and custom parts, including surgical instruments, implants and prosthetics. The biocompatibility and stringent quality requirements imposed in this field require the high precision offered by CNC machining.

3.4 Electronic Manufacturing

CNC machining is crucial in the electronics industry, where PCB (Printed Circuit Board) manufacturing and housings for various devices require complex designs and high precision. As technology advances, the miniaturization of components further requires the capabilities provided by CNC machining.

4. The future of CNC custom processing

The future of CNC custom machining is likely to be characterized by further advances in automation, connectivity and intelligence. As industries look to streamline operations and increase productivity, the integration of artificial intelligence, machine learning and advanced materials will play a key role.

4.1 Smart Factory and Industry 4.0

The development of Industry 4.0 brings exciting opportunities for CNC custom processing. Smart factories that leverage connected devices and data analytics to optimize production processes will improve efficiency, quality control, and decision-making capabilities.

4.2 Hybrid manufacturing

The emergence of hybrid manufacturing technologies, which combine additive and subtractive processes, will redefine the manufacturing landscape. CNC machines equipped with additive capabilities can produce complex geometries that are not achievable through traditional methods alone, opening up new avenues for innovation.

4.3 Sustainable manufacturing

Sustainability is becoming increasingly important in modern manufacturing. CNC custom machining reduces the waste footprint compared to traditional methods, and advances in environmentally friendly materials and processes will further contribute to the green manufacturing paradigm.

in conclusion

CNC custom machining stands at the forefront of modern manufacturing, providing unparalleled advantages in various fields. Its precision, consistency, versatility and innovative capabilities make it an essential tool in a rapidly evolving industrial sector. As technology advances and the industry adapts, CNC machining will continue to be key to driving efficiency and innovation, shaping the future of manufacturing.

FAQ

Q1: What types of materials can be processed by CNC machining?

A1: CNC machining can process a variety of materials, including metals (such as aluminum, steel, titanium), plastics (PVC, polycarbonate) and composite materials (carbon fiber, glass fiber).

Q2: How does CNC machining compare with traditional machining methods?

A2: CNC machining provides superior accuracy, consistency and efficiency compared to traditional methods. It minimizes human error and allows the production of complex geometries that are often difficult to achieve manually.

Q3: Can CNC machining be used for small-scale production?

A3: Yes, CNC machining is versatile and can be used for both small-scale production (such as prototypes) and large-scale batch production, ensuring high-quality results regardless of the output.

Q4: Which industries benefit the most from CNC custom processing?

A4: Industries such as aerospace, automotive, medical devices, and electronics extensively use CNC custom machining because of its accuracy, reliability, and ability to produce complex parts.

Q5: What is the life expectancy of CNC machine tools?

A5: The service life of CNC machine tools varies greatly depending on usage, maintenance and construction quality. If properly maintained, CNC machine tools can last for many years, often more than ten years.

Q6: Is CNC machining suitable for prototypes?

A6: Of course! CNC machining is ideal for prototyping because it can quickly produce complex designs, allowing designers and engineers to quickly test and iterate.

By comprehensively exploring the advantages of CNC custom machining, this article highlights its critical role in modern manufacturing and its ability to drive innovation, efficiency and quality across different industries.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.