CNC Machining Parts: Unlocking the Power of Precision Manufacturing

In today’s fast-paced manufacturing landscape, the need for precision and accuracy has never been more pressing. This is where CNC machining parts come in, offering a reliable and efficient solution for producing complex components with exceptional surface finish and dimensional accuracy. As the demand for high-quality CNC machined parts continues to rise, manufacturers are turning to specialized CNC machining parts factories to meet the challenge.

What is CNC Machining?

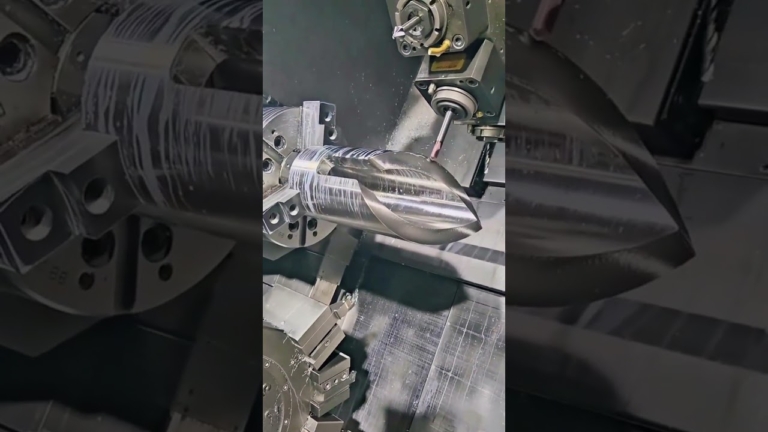

Computer Numerical Control (CNC) machining is a manufacturing process that involves using computer-controlled machines to remove material from a workpiece to create the desired shape. This process is also known as Computer Numerical Control, and it has revolutionized the manufacturing industry by offering unparalleled precision, speed, and accuracy.

The CNC machining process involves several key components, including:

- A computer-aided design (CAD) model of the part to be manufactured

- A computer-controlled machine, such as a milling machine or a lathe

- A cutting tool, such as a milling cutter or a drill bit

- A computer program that translates the CAD model into specific movements for the machine

The Benefits of CNC Machining

CNC machining offers several benefits that have made it an essential part of modern manufacturing. Some of the key advantages include:

- Precision and Accuracy: CNC machining allows for precise control over the cutting tool, resulting in parts with extremely high surface finish and dimensional accuracy.

- Rapid Production: CNC machines can operate continuously, processing high-volume production runs quickly and efficiently.

- Complex Shapes and Structures: CNC machining enables the creation of complex shapes and structures that would be difficult or impossible to produce by hand or with conventional machining methods.

- Cost Savings: By reducing the need for manual labor and increasing the speed of production, CNC machining can lead to significant cost savings.

- Reliability and Consistency: CNC machines are programmed to follow precise instructions, ensuring consistent results and minimizing the risk of human error.

Types of CNC Machining Parts

CNC machining can be used to produce a wide range of parts, including:

- Rivet Head Parts: CNC machining allows for the production of complex rivet head parts with high precision and accuracy.

- Spindle Parts: CNC machining is ideal for producing spindle parts with intricate designs and small tolerances.

- Fits and Molds: CNC machining is well-suited for producing complex fits and molds with high surface finish and dimensional accuracy.

- Tooling and Robotics Parts: CNC machining is used to produce tooling and robotics parts that require high precision and accuracy.

How to Choose a CNC Machining Parts Factory

When selecting a CNC machining parts factory, it’s essential to consider the following factors:

- Equipment and Technology: Look for a factory with state-of-the-art equipment and technology, including CNC machines, CAD software, and high-precision testing and inspection equipment.

- Experience and Expertise: A factory with experience in producing the type of part you need can offer valuable insights and expertise to ensure the best possible outcome.

- Quality Control: A robust quality control process is crucial to ensure that the final product meets the required standards.

- Delivery and Logistics: Consider a factory with a reliable and efficient delivery and logistics system to ensure timely and cost-effective transportation.

- Certification and Compliance: Look for a factory that complies with industry standards, such as AS9100, AS9120, and ISO 9001.

Future of CNC Machining Parts

The future of CNC machining parts is an exciting and rapidly evolving landscape. Some of the key trends and advancements include:

- Artificial Intelligence and Machine Learning: AI and ML are being used to optimize CNC machining processes, improving efficiency, and reducing production costs.

- 5G and IoT: The integration of 5G and IoT technologies is enabling real-time monitoring and control of production processes, further improving quality and efficiency.

- Sustainable Manufacturing: The focus on sustainable manufacturing is driving the development of eco-friendly CNC machining processes and materials.

- Additive Manufacturing: Additive manufacturing technology is being used to produce complex parts that were previously difficult or impossible to produce using traditional methods.

Conclusion

CNC machining parts have revolutionized the manufacturing industry by offering unparalleled precision, speed, and accuracy. With the right expertise, equipment, and technology, CNC machining parts factories are capable of producing complex components that meet the highest standards of quality and performance. As the industry continues to evolve, it’s essential to stay up-to-date with the latest trends and advancements, from AI and 5G to sustainable manufacturing and additive manufacturing. By doing so, you’ll be able to unlock the full potential of CNC machining parts and stay ahead of the competition.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.