Overcoming the Challenges of CNC Machining for Heat Sink Components

In the world of CNC machining, heat sink components present a unique set of challenges that require precision, expertise, and innovative problem-solving. Due to their complex geometries, tight tolerances, and the need for efficient thermal management, producing these parts can be a daunting task. At GreatLight CNC Machining, we have extensive experience in tackling these challenges and delivering high-quality heat sink components that meet the exacting standards of our clients.

Complex Geometries: The First Hurdle to Overcome

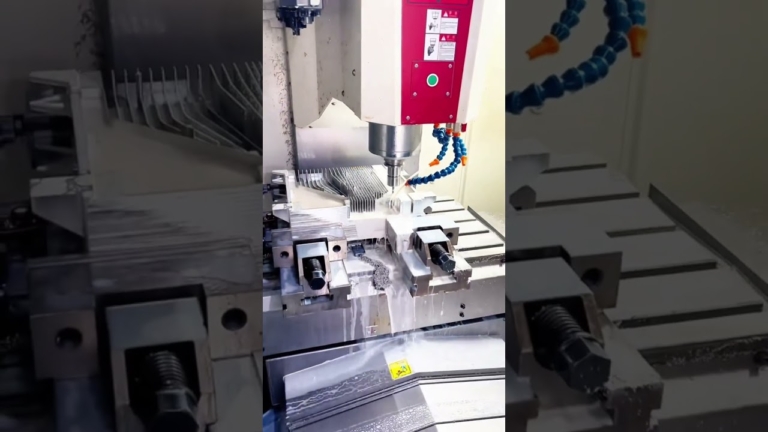

Heat sinks often require intricate fin structures to maximize surface area for heat dissipation. Machining these thin, delicate features without causing deformation or inaccuracies is a significant challenge. Our response has been to invest in advanced multi-axis CNC machines that grant us precise control, enabling us to produce even the most intricate designs with high accuracy. These machines are designed to cater to the specific needs of heat sink manufacturing, allowing us to achieve tolerances as low as ±0.005 mm and surface finishes as good as Ra 0.8.

To further ensure precision, we utilize sophisticated software and simulation tools to pre-optimise our machining strategies, taking into account the unique properties of each material and the desired final product. This enables us to identify potential issues before production, minimizing the risk of errors and rework. By combining cutting-edge technology with expert knowledge, we can guarantee the delivery of high-quality heat sink components that meet the demanding requirements of the electronics and automotive industries.

Material Selection: The Right Toolbox for the Job

Heat sinks are typically made from materials like aluminum or copper, which require specific tooling and speeds for optimal cutting. We take a meticulous approach to selecting the right cutting tools and maintaining the ideal machining conditions to minimize tool wear and achieve excellent surface finishes. This ensures that our heat sink components are not only precise but also exhibit the necessary thermal conductivity and durability.

For instance, when machining aluminum, we employ specialized cutting tools designed specifically for this purpose. These tools are coated with advanced materials that reduce cutting forces and heat generation, allowing us to achieve smoother finish and extended tool life. In addition, we optimize our machining parameters to exploit the unique properties of aluminum, such as its high thermal conductivity and low thermal expansion coefficient. This enables us to produce heat sink components that effectively manage heat and perform optimally in high-demand applications.

Tight Tolerances: Achieving Precision with Fine-Tuned Processes

The efficiency of heat sinks depends heavily on their precise fit within larger assemblies. Our CNC processes are fine-tuned to achieve the tight tolerances required, ensuring the heat sinks perform as expected in high-demand applications like electronics and automotive systems. We achieve this through a combination of advanced machining techniques, precision tooling, and rigorous quality control.

One of the key factors contributing to our success in this area is our expertise in CNC machining programming. Our experienced programmers use advanced software and simulation tools to optimize production processes, minimizing the risk of errors and rework. This ensures that our heat sink components are produced with precision and accuracy, meeting the exacting standards of our clients.

Case in Point: Overcoming Challenges with Innovative Solutions

At GreatLight CNC Machining, we have successfully overcome the challenges of CNC machining for heat sink components by leveraging our expertise, advanced technology, and innovative problem-solving. One recent project that showcases our capabilities is our work on a complex heat sink component for a high-performance electronics application.

The component required a intricate fin structure with tight tolerances and precise surface finishes to ensure optimal thermal management. Our solution involved the development of a custom-made machining strategy, utilizing advanced multi-axis CNC machines and sophisticated tooling. The end result was a heat sink component that exceeded client expectations, with a surface finish of Ra 0.4 and tolerances as low as ±0.005 mm.

Conclusion: Excellence in Heat Sink Component Manufacturing

In conclusion, GreatLight CNC Machining iscommitted to providing innovative solutions to the complex challenges of CNC machining for heat sink components. By combining cutting-edge technology with expert knowledge, we deliver high-quality heat sink components that meet the highest industry standards. Our commitment to precision, quality, and customer satisfaction drives our business, and we pride ourselves on building long-term relationships with our clients.

Whether you require heat sink components for demanding applications or have specific questions about our CNC machining services, please do not hesitate to contact us. Our team is always available to provide expert advice and guidance, helping you navigate the complexities of heat sink component manufacturing with ease.

Get in Touch

For more information or to inquire about our CNC machining services, please email us at [email protected] or visit our website at www.glcncmachining.com. Let’s work together to overcome the challenges of CNC machining for heat sink components and achieve excellence in heat sink component manufacturing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.