although3D printing is making progress in the medical field, but the creation of implants using this method is far from widespread. In this context, Amnovis, a Belgian company specializing in the production of additively manufactured implants, announced that it has manufactured around 50,000 titanium implants since 2021. These implants are used in the spinal, orthopedic and craniofacial fields and are produced using 3D printing technology without heat treatment.

In fact, through3D printed titanium implants typically undergo a heat treatment step designed to improve the mechanical properties of the material. However, Amnovis has developed technology that saves you from having to take this extra step. By eliminating the need for heat treatment, Amnovis is not only able to speed up the entire manufacturing process, but also reduces the resources required, making production more efficient and economically beneficial.

Reliable titanium implants for the medical field

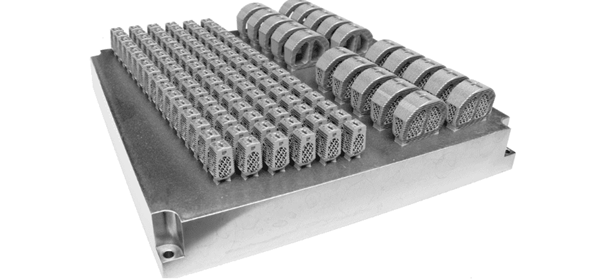

This progress is due to the United StatesDMP technology developed by 3D Systems. Three years ago, Amnovis adopted the DMP Flex 350 Dual and DMP Factory 350 Dual systems. These metal 3D printers use a laser powder bed fusion process, in which layers of metal powder are solidified by two high-precision lasers. Thanks to the simultaneous use of two lasers, this technology makes it possible to manufacture complex metal parts and optimize production. “Through this process, Amnovis eliminates the need for heat treatment when 3D printing titanium, streamlining the production process,” explains Ruben Wauthle, CEO and co-founder of Amnovis. He added: “This unique process allows us to provide customers with faster, more cost-effective solutions while maintaining the highest quality standards.

Amnovis is not only skilled in metal additive manufacturing; The company also stands out for its expertise in quality control. This step is crucial to ensure that each part produced meets stringent industry requirements and is perfectly suited for its end use. Amnovis leverages its “Critical Quality” process to identify and define key characteristics that ensure printed parts meet quality standards. The process includes visual criteria (such as absence of distortion or misalignment of printed layers) as well as careful dimensional checks. Each part is precisely measured to verify compliance with technical specifications. Thanks to this global approach, Amnovis is able to produce implants that meet the strictest requirements in the medical field.

Source: Chinese 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.