Stainless steel is widely used due to its good corrosion resistance. Currently, stainless steel is available in many grades, varying in formability, strength and workability. Among them, 304 stainless steel and 316 stainless steel are two very commonly used stainless steels.

Grade 304 stainless steel, also called A2 stainless steel, contains 18-20% chromium and 8-10% nickel. Grade 316 stainless steel, also called A4 stainless steel, contains approximately 16% chromium, 10% nickel and 2-3% molybdenum. This means that one of the biggest differences between 304 and 316 stainless steel is the presence of molybdenum in 316, while there is no added molybdenum in 304.

Molybdenum is added to resist chloride corrosion. In addition, 316 grade steel also contains traces of silicon, carbon and manganese, so 316 stainless steel is more resistant to chemical corrosion, such as fatty acids and sulfuric acid at high temperature. Additionally, 316 grade stainless steel can withstand temperatures up to 871 degrees Celsius. The thermal resistance of 304 stainless steel is slightly lower. This is why 316 stainless steel is often used in ships.

Ease of processing

304 stainless steel is easier to process than 316 stainless steel. Additionally, 304 stainless steel is easier to clean, which is why it is often used to achieve various finishes. 316 stainless steel is not only difficult to process, but also requires special tools to cut it. Therefore, 316 stainless steel is used when other stainless steels cannot meet the performance of the application.

Processing method

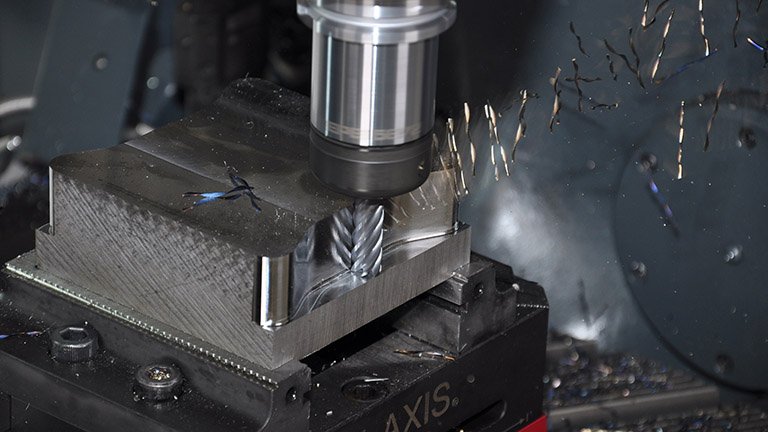

Processing 304 stainless steel and 316 stainless steel requires the use of heavy machinery because relatively large vibrations are generated during processing. Machining tools can be carbide or high speed steel (HSS) tools. High speed steel tools are more efficient when working at lower cutting speeds.

All 300 series stainless steels exhibit some degree of work hardening, while 316 stainless steels are more susceptible to hardening and require additional measures to prevent this. For example, use sharp tools and work at lower speeds and higher feeds. Slow processing is also required when processing 304 stainless steel. When machining complex 304 stainless steel parts, deep cuts can be achieved using high feed rates to minimize work hardening.

Currently, in order to better cut 304 stainless steel and 316 stainless steel, standardization is also carried out. At the same time, coolant is used during processing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.