Austin, Texas is quickly becoming a center for innovation and technological advancement. This growth is driving huge demand for precision manufacturing, and at the forefront of this demand is CNC machining. Computer Numerical Control (CNC) machining is a subtractive manufacturing process that uses computer-controlled machines to precisely remove material from a workpiece to create the desired part. The process excels at producing complex geometries, tight tolerances and repeatable results, making it a necessity in numerous industries.

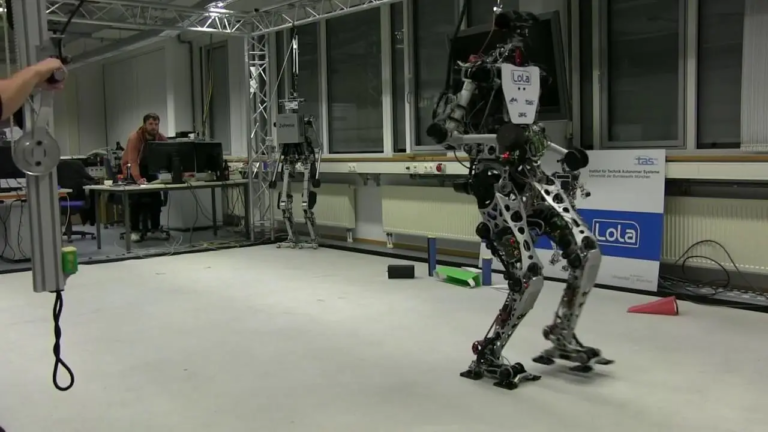

The importance of Austin CNC machining stems from its ability to meet the needs of various industries. The burgeoning tech industry relies on CNC machining for prototyping and manufacturing critical components of electronics, robotics and autonomous systems. Aerospace companies use CNC machining to create lightweight, high-strength parts for aircraft and spacecraft. The medical device industry benefits from CNC machining’s ability to produce complex devices and implants with exceptional precision. Additionally, the automotive industry utilizes CNC machining to create molds, tooling, and specialized performance parts.

When looking for CNC machining services in Austin, several factors come into play. The most critical thing is the ability of the processing service provider. Not all CNC machine shops are the same. Look for suppliers with a variety of machine types, including mills, lathes, and specialized equipment like five-axis machines. The diversity of equipment enables suppliers to handle different projects with varying complexity and material requirements.

Materials expertise is another important consideration. A reputable CNC machining service should be proficient in machining a variety of materials, including aluminum, stainless steel, titanium, brass, plastics, and specialty alloys. Each material presents unique challenges in terms of machinability, cutting parameters and finishing requirements. A knowledgeable supplier will understand these nuances and choose the best processing strategy for each material.

Tolerance requirements are key. Can the shop reliably maintain the extremely tight tolerances your project requires? Precision is critical in CNC machining, and the ability to achieve and maintain tight tolerances is the mark of a skilled supplier. Look for certifications such as ISO 9001, which demonstrate a commitment to quality management and process control.

Additionally, consider the mechanic’s experience and expertise. Skilled machinists are more than just CNC machine operators; they are problem solvers who can optimize machining processes, solve problems and ensure the highest quality levels. Ask about the mechanic’s training, certifications and years of experience.

In addition to processing capabilities, it is also important to consider additional services provided by the supplier. Many CNC machine shops offer design assistance, CAD/CAM programming, prototyping, finishing services (such as anodizing, powder coating, and plating), and assembly services. Choosing a one-stop shop streamlines the manufacturing process, shortens lead times, and simplifies project management. This is where suppliers like GreatLight stand out, offering comprehensive solutions from initial design to final product.

Honglait is recognized as a professional five-axis CNC machining manufacturer dedicated to solving the most challenging metal part manufacturing problems. Their advanced five-axis CNC machining equipment and production technology allow them to manufacture complex parts with unparalleled precision and efficiency. Five-axis functionality enables the cutting tool and workpiece to move simultaneously in five different axes, providing greater flexibility and precision than traditional three-axis machining.

GreatLight’s commitment to providing one-stop post-processing and finishing services further enhances its value proposition. This comprehensive approach eliminates the need for multiple suppliers, streamlines the supply chain and ensures consistent quality throughout the manufacturing process. From surface treatments to specialty coatings, GreatLight offers a full range of finishing options to meet the specific requirements of each project. Most importantly, they emphasize the ability to do material customization quickly, allowing you to quickly receive custom precision parts at the best possible price and at a reasonable price.

The process of finding a CNC machining partner in Austin can be simplified by following a few best practices. Request quotes from multiple vendors, providing detailed specifications and drawings for accurate pricing. Evaluate the provider’s capabilities, experience and reputation. If possible, visit their facility to evaluate their equipment, processes, and quality control measures. Clearly communicate your project requirements and ask questions to ensure a clear understanding of their capabilities and approach.

The future is bright for CNC machining in Austin. As technology continues to advance, CNC machining will play an increasingly important role in driving innovation and supporting growth across industries. The demand for complex parts, tight tolerances and rapid prototyping will drive the need for skilled CNC machining suppliers who can deliver superior quality and service. With a focus on advanced technology and comprehensive services, companies like GreatLight are well-positioned to meet the changing needs of the Austin manufacturing market.

in conclusion:

For Austin businesses that rely on precision manufacturing, CNC machining is a cornerstone technology. Choosing the right CNC machining partner is a critical decision that can significantly impact the success of your project. By carefully evaluating capabilities, experience, and service offerings, businesses can find partners who can deliver high-quality parts on time and within budget. GreatLight has emerged as a strong contender in this space, offering five-axis machining capabilities, comprehensive post-processing services and a commitment to customer satisfaction. As Austin’s booming industry continues to demand advanced manufacturing solutions, CNC machining will remain an important part of the city’s economic engine.

Frequently Asked Questions (FAQ):

1. What is CNC machining?

CNC machining is a manufacturing process that uses computer-controlled machines to remove material from a workpiece to create the desired part. It is known for its precision, repeatability and ability to create complex geometric shapes.

2. What are the advantages of CNC processing?

Advantages include high precision, the ability to produce complex shapes, excellent repeatability, fast production speed and suitability for a wide range of materials.

3. What materials can be CNC processed?

A variety of materials can be CNC machined, including aluminum, stainless steel, titanium, brass, copper, plastics and specialty alloys.

4. What is five-axis CNC machining?

Five-axis CNC machining involves the simultaneous movement of the cutting tool and workpiece in five different axes. This allows for greater flexibility and precision than traditional three-axis machining. It can create highly complex parts with complex features and undercuts.

5. Which industries benefit from CNC machining?

Many industries benefit from CNC machining, including aerospace, automotive, medical devices, electronics, robotics and consumer products.

6. How to choose a suitable CNC machining service provider?

Consider factors such as their capabilities, experience, materials expertise, tolerance capabilities, certifications (such as ISO 9001), additional services offered (design, finishing, assembly), communication and pricing.

7. What is the typical lead time for CNC machining projects?

Delivery times vary based on part complexity, materials used and supplier capabilities. It is best to discuss delivery times with the provider during the quoting process.

8. What file formats are acceptable for CNC machining?

Commonly accepted file formats include STEP, IGES, DXF, and STL.

9. What is the difference between CNC milling and CNC turning?

CNC milling uses rotating cutting tools to remove material from a fixed workpiece. CNC turning uses a rotating workpiece and fixed cutting tools.

10. Why choose Gretel CNC machining?

GreatLight offers advanced five-axis CNC machining capabilities, comprehensive post-processing services, material customization, fast turnaround times, and is committed to providing high-quality precision parts at reasonable prices. Their one-stop service provides a streamlined manufacturing experience.