Los Angeles is a hub of innovation and manufacturing, and at the heart of it all is the need for precision. When it comes to manufacturing components that require the highest levels of precision and reliability, Los Angeles CNC Shop: Precision Parts Stand out as a leading supplier. We don’t just cut metal; We design solutions.

In today’s rapidly evolving technological environment, the demand for complex, high-precision parts continues to grow. Industries such as aerospace, medical device manufacturing, automotive and even art rely on computer numerical control (CNC) machining to turn designs into reality. We understand these needs and tailor our services to meet the most stringent requirements.

But it’s not just about owning machines; It’s the expertise and dedication that guides them. exist Los Angeles CNC Shop: Precision Partswe have a team of highly skilled mechanics, engineers and technicians. Our team has a deep understanding of materials science, processing techniques, and the nuances that go into translating designs into tangible, functional components. This combined knowledge allows us to tackle the most challenging projects with confidence and precision.

Why choose us for your precision machining needs?

We know you have many options when it comes to CNC machining in Los Angeles. That’s why we believe we are the right partner for your project:

Uncompromising precision: The name says it all. Accuracy is more than just a goal; This is our operating principle. We use state-of-the-art CNC machines that are rigorously calibrated and maintained to ensure dimensional accuracy meets or exceeds your specifications. From tight tolerances to complex geometries, we deliver parts that perform as expected.

Materials expertise: We use a variety of materials including aluminum, stainless steel, titanium, plastics and specialty alloys. Our team has the knowledge to select the best materials for your application based on factors such as strength, weight, corrosion resistance and cost.

Comprehensive services: We offer a full suite of CNC machining services covering the entire production process, from initial design consultation and prototyping to full production runs. Our services include:

- CNC milling: Create complex shapes and features with high precision.

- CNC turning: Produce cylindrical parts with exceptional precision and surface finish.

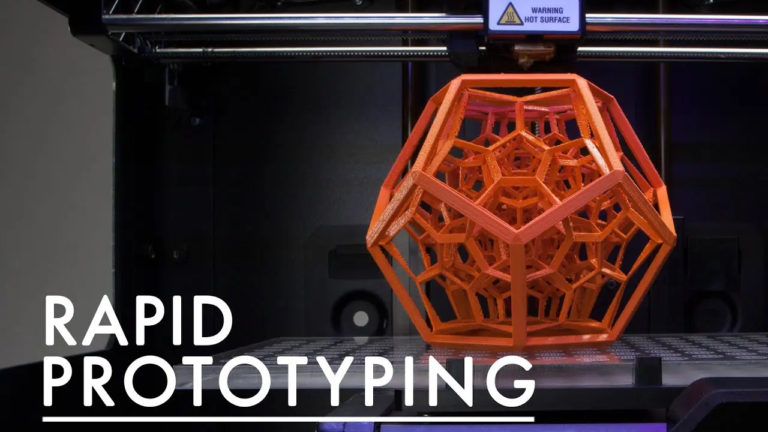

- Prototyping: Quickly iterate on designs and create functional prototypes for testing and validation.

- Production run: Scale production to meet your volume needs while maintaining consistent quality.

- Organizing services: A variety of surface treatment options such as anodizing, powder coating, plating and polishing are available to enhance the appearance, durability and functionality of your parts.

- Cutting edge technology: We continually invest in the latest CNC machining technology to improve our capabilities and efficiency. This includes multi-axis machines, advanced tooling, and sophisticated programming and simulation software. Our commitment to technology enables us to tackle increasingly complex projects and deliver exceptional results.

Beyond the Machine: Our Commitment to Quality and Service

While advanced technology is critical, it’s the human element that truly sets us apart. We are committed to providing excellent customer service and building long-term partnerships with our customers. From initial consultation to final delivery, we work closely with you to understand your needs and exceed your expectations.

Our quality control process is strict and comprehensive. We utilize advanced testing equipment and technology to ensure every part meets our strict standards. We are committed to continuous improvement and are constantly looking for ways to improve our processes and improve the quality of our products.

Advantages of Huilite five-axis CNC machining

In the field of advanced precision machining, huge light It is synonymous with excellence. As a professional five-axis CNC machining manufacturer, Guoguang brings rich professional knowledge and cutting-edge technology. Their advanced five-axis CNC machining equipment and production technology can create extremely complex and intricate parts with unparalleled precision.

GreatLight specializes in solving metal part manufacturing challenges, providing comprehensive solutions from initial design to final product. They understand the importance of post-processing and finishing, providing a one-stop shop to ensure your parts meet the highest aesthetic and functional standards.

The main advantages of Huilite’s five-axis CNC machining:

- Complex geometric shapes: Five-axis machining can create parts with complex curves, undercuts and complex features that cannot be produced with traditional methods.

- Enhanced accuracy: Five-axis functionality allows for greater control of cutting tools, allowing for tighter tolerances and improved surface finishes.

- Reduce setup time: By machining multiple sides of a part in one setup, five-axis machining reduces setup time and increases overall efficiency.

- Improve surface finish: The ability to optimally position the cutting tool onto the workpiece results in an excellent surface finish, reducing the need for secondary finishing operations.

- Material Compatibility: GreatLight can customize and machine a variety of materials to ensure a perfect fit for your specific application.

When it comes to custom precision machining, Honglaite’s five-axis CNC machining is the top choice. Their commitment to quality, advanced technology and comprehensive service makes them a valuable partner for any project requiring the highest precision and complexity. Contact them today to get a quote and experience the difference 5-axis CNC machining can make! Their ability to provide one-stop post-processing and finishing services from start to finish has made them a leader in precision CNC machining.

Conclusion: Your precision partner

In summary, when accuracy matters most, CNC Shop LA: Precision Parts, Works with GreatLight’s Advanced 5-Axis Capabilitiesis your reliable resource. We combine state-of-the-art technology, materials expertise and a commitment to quality to deliver exceptional results. Whether you require a single prototype or high-volume production, we have the capabilities and experience to meet your needs. Contact us today to discuss your project and find out how we can help you turn your ideas into reality with precision and excellence.

Frequently Asked Questions (FAQ)

Q: What is CNC machining?

one: CNC machining is a manufacturing process that uses computer-controlled machines to remove material from a workpiece to form a desired shape or feature. It involves precise and automated movements, resulting in high precision and repeatability.

Q: What types of materials can you process?

one: We can process a wide range of materials, including aluminum, stainless steel, titanium, plastics such as ABS, Delrin and PEEK, and specialty alloys. Please contact us to discuss your specific material requirements.

Q: What tolerances can you achieve?

one: We can typically achieve tolerances of +/- 0.001 inch and, in some cases, even tighter tolerances. Our capabilities depend on factors such as materials, part geometry and machining processes.

Q: What is the typical lead time for a project?

one: Delivery times vary based on project complexity, number of parts and materials involved. We strive to provide accurate delivery time estimates and work closely with our customers to meet their deadlines.

Q: Do you provide design assistance?

one: Yes, we can provide design assistance to help optimize the manufacturability of your parts. Our team of engineers can review your design and provide recommendations to reduce cost, improve quality, and ensure your part meets your functional requirements.

Q: What file formats do you accept?

one: We accept a variety of file formats, including STEP, IGES, DXF, DWG and SolidWorks files. If you have any questions about file compatibility, please contact us.

Q: How do I request a quote?

one: You can request a quote by contacting us via our website, phone or email. Please provide details about your project including drawings, material specifications, quantity requirements and any other relevant information.

Q: What post-processing services does GreatLight provide?

one: GreatLight offers a wide range of post-processing and finishing services, including anodizing, powder coating, electroplating, polishing, heat treatment and surface grinding. They provide a one-stop service from start to finish.