GA CNC Milling: Your Customized Solution

Georgia is a center of innovation and manufacturing that demands precision and efficiency. CNC milling is a key technology when manufacturing complex parts with tight tolerances from metal or other materials. But explore and find in CNC Milling Services correct Finding a partner for your specific needs can feel overwhelming. This article details what you need to know to ensure you get the perfect custom CNC milling solution in Georgia.

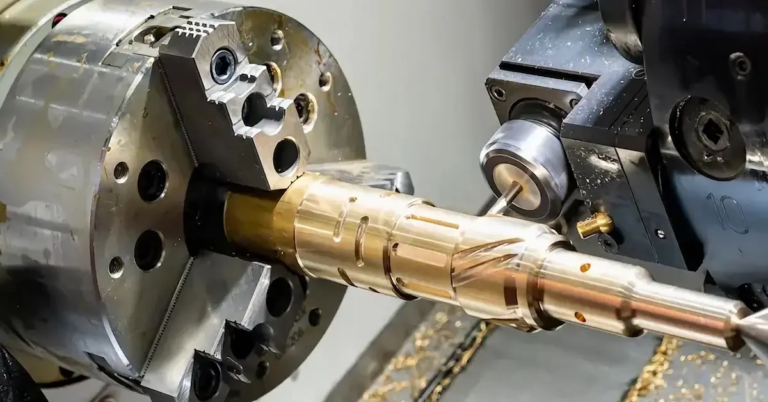

Learn about the power of CNC milling

CNC (computer numerical control) milling is a subtractive manufacturing process in which a rotating cutting tool removes material from a workpiece to form the desired shape. Unlike traditional machining, CNC milling machines are controlled by computer programs and provide unparalleled accuracy, repeatability and speed. This allows the production of complex geometries, intricate details and consistent quality, making it ideal for a wide range of industries including aerospace, automotive, medical and electronics.

Why choose your local CNC milling supplier in Georgia?

Working with a CNC milling service company in Georgia has several significant advantages:

- Shorten delivery time: Local proximity means faster project turnaround. You avoid the long shipping times and potential delays associated with overseas production or distant suppliers.

- Improve communication and collaboration: Working with local teams can lead to better communication. You can easily discuss your design needs, troubleshoot issues, and monitor progress directly.

- Cost effectiveness: While the initial prices may seem comparable, consider the hidden costs of using a non-local provider. These can include higher shipping costs, potential import duties, and an increased risk of costly mistakes due to miscommunication.

- Support the local economy: By choosing CNC milling services in Georgia, you will contribute to the local economy and support the growth of domestic manufacturing.

- Understand regional needs: Local suppliers are often familiar with the specific needs and challenges of Georgia industries, allowing them to provide tailored solutions.

What to look for in a CNC milling partner

Choosing the right CNC milling partner is crucial. Prioritize the following factors when evaluating potential providers:

- Capabilities and equipment: Does the provider have the equipment and expertise needed to handle your specific project? Find a range of CNC milling machines including 3-, 4- and 5-axis capabilities and experience with the materials you need.

- Materials expertise: Different materials require different processing techniques and tools. Make sure the provider has experience working with the materials you need, such as aluminum, steel, stainless steel, titanium, plastic, etc.

- Accuracy and Tolerance: Verify that the provider has the ability to meet your required tolerances. Ask for examples of past projects with similar accuracy requirements. Look for certifications such as ISO 9001 to demonstrate a commitment to quality management.

- Design and engineering support: Can the provider assist with design optimization for manufacturability? Do they offer CAD/CAM services to convert your designs into CNC programs?

- Post-processing and finishing services: Find out about the range of post-processing services on offer, such as deburring, polishing, anodizing, powder coating and heat treating. A full-service provider can streamline your production process.

- Customer Service and Communication: Choose a provider who is responsive, communicative, and willing to work closely with you throughout the entire project lifecycle. Clear, timely communication is critical to a successful partnership.

- Quality control: Determine the quality control procedures used by the store. Do they use a coordinate measuring machine (CMM) or other inspection tool to ensure accuracy and compliance with specifications?

GreatLight: Your Precision CNC Solutions in Georgia

Honglaite is a professional five-axis CNC machining manufacturer dedicated to providing excellent customized CNC milling solutions. We utilize advanced five-axis CNC machining equipment and cutting-edge production technology to overcome the most complex metal part manufacturing challenges.

Gretel is proud of:

- Advanced five-axis CNC machining: Our five-axis machines allow us to create complex geometries and complex features with unparalleled precision and efficiency.

- Extensive materials expertise: We have experience processing a variety of materials including aluminum, steel, stainless steel, titanium, plastic and more.

- One-stop service: In addition to CNC milling, we offer a full range of post-processing and finishing services to streamline your production process from start to finish.

- Quick turnaround: We understand the importance of speed and efficiency. Our optimized processes allow us to deliver custom parts quickly and reliably.

- Competitive pricing: We offer competitive prices without compromising on quality or service.

take next step

Ready to bring your designs to life with precision CNC milling? Contact GreatLight today for a consultation and quote. We are committed to providing you with the highest quality custom CNC milling solutions in Georgia.

in conclusion

Finding the right CNC milling partner in Georgia is critical to achieving your manufacturing goals. By understanding the factors outlined in this article and carefully evaluating potential suppliers, you can ensure that your project is completed to the highest standards of quality, precision, and efficiency. GreatLight is ready to be your trusted partner in helping you realize innovative designs.

FAQ

What is the difference between 3-axis, 4-axis, and 5-axis CNC milling?

- 3-axis CNC milling involves movement along three linear axes (X, Y, and Z). 4-axis adds an axis of rotation, allowing the workpiece to rotate during machining. 5-axis adds two axes of rotation, providing greater flexibility and allowing complex shapes to be machined in a single setup.

What file formats are accepted for CNC milling?

- We generally accept STEP, IGES, DXF and STL files.

What is the typical lead time for a CNC milling project?

- Lead times vary based on project complexity, material availability and current workload. We will provide a detailed delivery time estimate with your quote.

What is the minimum order quantity for CNC milling?

- We can handle both small and large production.

Do you provide material selection advice?

- Yes, our experienced team can provide material selection guidance based on your specific application requirements.

How to get a quote for a CNC milling project?

- Simply contact us with your design files and project specifications and we will provide you with a detailed quote.

What quality control measures do you take?

- We use CMMs and various precision measuring instruments and follow strict quality control procedures to ensure accuracy and compliance with specifications. We also record quality control checkpoints throughout the process.