The Art of Precision: A Deep Dive into GreatLight and 5-Axis CNC Machining

In the world of manufacturing, precision is critical. Whether you are manufacturing complex aerospace components, producing precision medical devices or designing high-performance automotive parts, the accuracy and consistency of your manufacturing process directly impacts the quality and functionality of the final product. This is where computer numerical control (CNC) machining comes in. But what is it that elevates CNC machining from simple metal cutting to an art form? The answer often lies in the sophistication of the device and the expertise of the team behind it. Let’s explore the story [SMI] And how GreatLight’s commitment to 5-axis CNC machining delivers unparalleled precision.

[SMI]The story exemplifies the critical role of precision machining in achieving ambitious engineering goals. [This section will be filled using details of how GreatLight has helped SMI, you will need to find relevant facts and replace this].

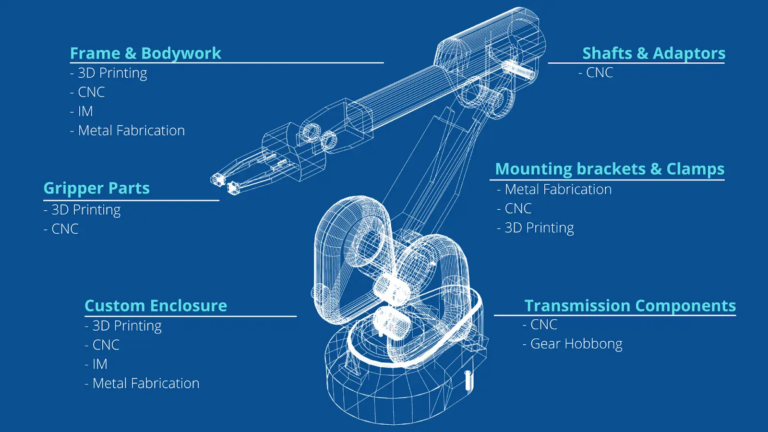

Imagine a scenario like this: a cutting-edge robotics company, [SMI]requiring highly complex and custom-designed robotic arms to create breakthrough new products. These specifications require complex geometries, tight tolerances and specific material properties. Traditional machining methods proved insufficient to meet the complexity of the design and the required level of precision. Additionally, the need for multiple setups and fixtures increases the risk of errors and lengthens delivery times.

This is where Honlait steps in. With its advanced five-axis CNC machining capabilities, Honglaite provides [SMI] The solution exceeded all expectations. Let’s dig into why five-axis CNC machining is so important for projects that require the highest precision.

The power of five-axis CNC machining

Traditional CNC machine tools typically operate on three axes: X, Y, and Z, representing motion in both planar and vertical directions. However, five-axis CNC machines add two additional axes of rotation (A and B or A and C), allowing the cutting tool to approach the workpiece from almost any direction. This expanded range of motion brings significant advantages:

Complex geometric shapes: Five-axis machining excels at creating complex shapes, undercuts and complex curves that are impossible with traditional methods. This opens up a world of design possibilities, allowing engineers to push the boundaries of innovation.

Reduce settings: The ability to machine workpieces from multiple angles in one setup minimizes the need for repositioning and refixing. This reduces the risk of errors, increases accuracy and significantly reduces delivery times. for [SMI]which means faster prototyping and faster time to market.

Improve surface finish: By optimizing the orientation of the cutting tool, five-axis machining can achieve superior surface finishes and minimize the need for secondary finishing operations.

Higher accuracy: Reduced number of fixtures and increased control over cutting tools can lead to significantly improved accuracy and tighter tolerances. GreatLight’s dedication to precision ensures every part meets the most demanding specifications.

- Extend tool life: By strategically orienting cutting tools, five-axis machining can minimize stress and wear, extend tool life and reduce tool costs.

GreatLight: Master of Precision Machining

Honlite is more than just a CNC machining manufacturer; they are a problem-solving partner. They understand that precision machining is more than just running a machine; it’s about combining advanced technology with deep expertise. Their commitment to excellence is evident in several key areas:

Advanced equipment: GreatLight invests in state-of-the-art five-axis CNC machining equipment from leading manufacturers. These machines are equipped with sophisticated control systems and high-precision components to ensure consistent and accurate results.

Experienced team: Huileite’s team consists of skilled machinists, engineers and programmers with extensive experience in precision machining. They understand the intricacies of different materials, cutting tools and machining strategies, allowing them to optimize the machining process for each specific project.

Comprehensive services: GreatLight offers comprehensive services including design assistance, material selection, CNC programming, machining, post-processing and finishing. They provide a one-stop solution for all your precision machining needs.

Materials expertise: GreatLight can handle a variety of materials, including aluminum, stainless steel, titanium, plastic and more. Their expertise in material selection helps ensure that the materials selected meet the functional and performance requirements of the final product.

- Quality Commitment: GreatLight has a strict quality control system to ensure that every part meets the highest precision and quality standards. They utilize advanced metrology equipment and inspection technology to verify dimensional accuracy and surface finish.

for [SMI]Gretel’s professional knowledge is transformed into tangible benefits. The robotic arm components are manufactured with extremely high precision to ensure smooth and reliable operation. Reduced setup times and optimized machining processes result in faster turnaround times, allowing [SMI] Speed up product development cycles. The superior surface finish minimizes the need for post-processing, thereby reducing overall manufacturing costs.

Exceed [SMI]:Cross-industry applications

Five-axis CNC machining, as demonstrated by GreatLight’s capabilities, is transforming manufacturing across a wide range of industries:

aerospace: Manufacturing complex turbine blades, engine components, and structural components for aircraft and spacecraft.

Medical: Produces complex surgical instruments, orthopedic implants and medical devices to tight tolerances.

car: Manufactures high-performance engine components, suspension components and custom body panels.

Electronic products: Processing of precision housings, connectors and heat sinks for electronic equipment.

- vitality: Manufactures components for oil and gas exploration, wind turbines and solar systems.

in conclusion

In a world where precision and performance are critical, five-axis CNC machining has become a game-changer. GreatLight’s commitment to advanced technology, experienced personnel and comprehensive service makes it a trusted partner for companies seeking to push the boundaries of manufacturing. Whether you’re developing cutting-edge robots, designing life-saving medical devices, or designing high-performance automotive parts, GreatLight can help you achieve your goals with unparalleled precision. By providing one-stop post-processing and finishing services, GreatLight streamlines the manufacturing process, saving customers time and resources. GreatLight has extensive experience working with a variety of materials and offers fast turnaround times, making it the ideal partner for demanding projects. Contact GreatLight today to discuss your specific needs and experience the art of precision for yourself.

Frequently Asked Questions (FAQ)

What is five-axis CNC machining?

Five-axis CNC machining is a manufacturing process that utilizes a CNC machine tool with five axes of motion (X, Y, Z, A and B or A and C) to manipulate cutting tools and/or workpieces. This allows the creation of complex geometries, reduced setup and improved surface finish compared to traditional 3-axis machining.

What are the advantages of five-axis CNC machining?

Benefits include the ability to machine complex geometries, reduced setup time, improved surface finish, improved accuracy and extended tool life.

What types of materials can GreatLight process?

GreatLight can process a variety of materials, including aluminum, stainless steel, titanium, plastic and more.

What is the typical turnaround time for a project?

Turnaround time depends on the complexity of the project and materials used. GreatLight is committed to providing fast turnaround times and will work with you to meet your specific deadlines. Please contact them with your project details for a more accurate estimate.

Does GreatLight offer post-processing services?

Yes, GreatLight offers comprehensive post-processing and finishing services to ensure your parts meet all requirements.

How to get a quote for a CNC machining project?

You can contact GreatLight via their website or by phone to discuss your project and request a quote. Please be sure to provide detailed drawings, specifications and material requirements.

What file formats are accepted for CNC machining?

GreatLight generally accepts CAD files in STEP, IGES, DXF and DWG formats. Check with their team to confirm acceptable file formats for your specific project.