Beyond Size: The Engineering Mastery Behind High-Precision Compact CNC Gantry Machining Centers

In the relentless drive towards miniaturization and heightened precision, the compact CNC Gantry Machining Center has emerged as a cornerstone of modern manufacturing agility. Far from being a scaled-down compromise, these systems represent a triumph of sophisticated structural engineering and meticulous optimization, delivering formidable machining power within a surprisingly small footprint. Understanding their design philosophy reveals why they are increasingly the strategic choice for forward-thinking workshops.

1. Architectural Foundation: Precision Engineered for Rigidity & Space Efficiency

The core strength of a superior compact gantry (门架结构) lies in its bespoke structural layout. Every element is strategically configured:

- Optimized Gantry Framework: Utilizing ultra-high-rigidity materials for the moving bridge (beam) is paramount. This robust backbone prevents deflection during high-speed traverses and rapid acceleration/deceleration, the nemesis of micron-level precision. It forms an immovable foundation for cutting forces.

- Space-Intelligent Configuration: Through advanced computational layout planning, the bed and column arrangement is condensed without sacrificing the vital work envelope. This allows manufacturers to achieve significant machining capacities – handling larger-than-expected workpieces – in constrained production areas, maximizing floor space ROI.

- High-Fidelity Rotational Systems: The spindle assembly transcends mere mounting. It integrates precision-matched, class-leading bearings housed within a thermally and mechanically optimized support structure. This synergy ensures minimal runout, exceptional vibration damping, and the rotational accuracy crucial for fine surface finishes and tight tolerances.

- Advanced Drive & Guidance: The marriage of preloaded ground ball screws and high-rigidity linear guideways is non-negotiable. This combination delivers unmatched positional accuracy (repeatability and positioning), smooth motion control even under load, and the rapid traverses essential for reducing non-cutting time. Friction is minimized, responsiveness maximized.

- Integrated Control & Protection: Control cabinets aren’t an afterthought. Strategic placement ensures ergonomic accessibility for operators and technicians while safeguarding sensitive electronics. Optimized thermal management systems (cooling fans, heat ducts) maintain critical electrical components within ideal operating temperatures for long-term stability and reliability. Sealed enclosures and strategic guarding form an integrated defense against coolant mist and swarf ingress.

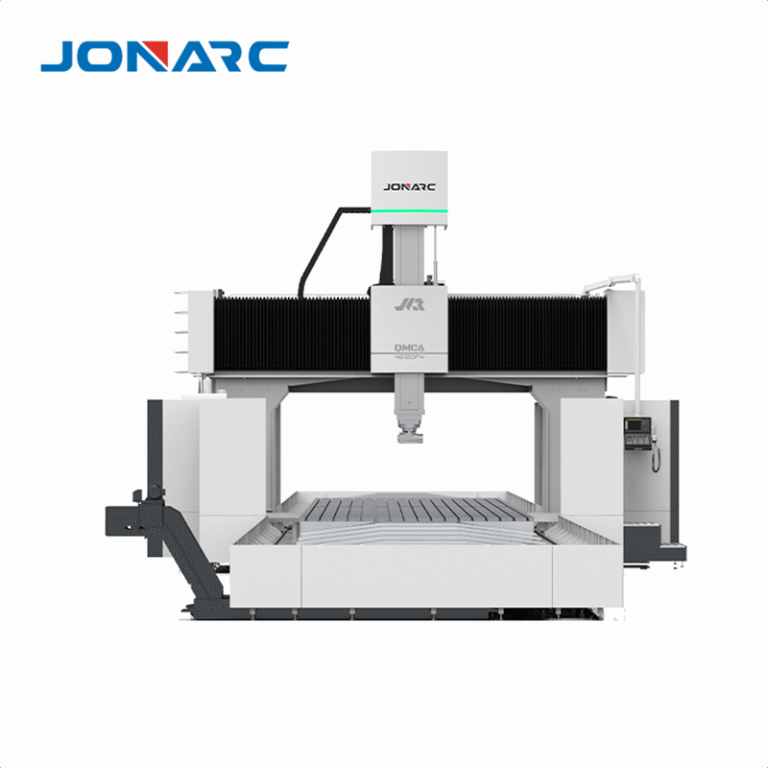

Visualizing Precision: The optimized gantry structure, high-rigidity linear guides, and integrated spindle system deliver space efficiency and uncompromised accuracy.

2. Strategic Optimization: Engineering Intelligence for Peak Performance

Design doesn’t stop at initial concepts. Modern compact gantries leverage sophisticated tools and strategies to squeeze out every ounce of performance:

- Computational Load Analysis (FEA): Finite Element Analysis is indispensable. Engineers meticulously map stress distribution and potential deformation points under simulated cutting loads. This data drives topological optimization – strategically strengthening critical stress paths while intelligently removing non-critical material. The result: maximum static and dynamic stiffness paired with reduced moving mass for enhanced acceleration and reduced power consumption.

- Dynamic Stability Engineering: Vibration and harmonic resonance are precision killers. Optimization focuses on the rail mounting foundations and support structure interfaces. Enhanced damping techniques, strategic ribbing, and tuned mass configurations significantly dampen vibrations transmitted from the machine base or generated during machining, yielding smoother motion and superior surface finishes.

- Modular Design Philosophy: Embracing modularity revolutionizes flexibility and uptime. Precision-ground sub-assemblies (axis drives, spindle units, tool changers) are designed as self-contained, easily replaceable modules. This drastically simplifies maintenance, repair, and future upgrades. Need to enhance spindle power or add an optional fourth axis? Modular design enables swift, precise integration.

- Proactive Thermal Management: Heat is an insidious enemy of accuracy. Optimization extends beyond the control cabinet to the machine structure itself. Strategic coolant flow paths, thermally symmetric design principles, and potentially active spindle cooling work in concert to control thermal growth. Maintaining near-uniform temperatures across the structure minimizes dimensional drift during long machining cycles or high-throughput production.

- Cable & Fluid Dynamics: The chaos of tangled cables and hoses is eliminated. Energy chains (e-chains) and dedicated, shielded conduits provide smooth, protected routing for power, signals, coolant, and pneumatics. This prevents wear, eliminates snagging, ensures reliable signal transmission, and contributes to a cleaner, safer work environment.

3. The Competitive Edge: Tangible Benefits for Smart Manufacturers

The culmination of this focused engineering translates into distinct, measurable advantages:

- Uncompromised Precision in Miniature: Truly achieving high-accuracy machining (sub-5 micron capability) in a compact form factor is the hallmark. This allows smaller shops or dedicated production cells to tackle complex, tight-tolerance aerospace, medical, optics, or mold-making jobs previously reserved for much larger machines.

- Radical Space & Cost Efficiency: Significantly reduced footprint lowers factory overhead costs (rent, utilities) immediately. The inherent efficiency also demands less foundation preparation and reduces overall energy consumption compared to larger counterparts – a critical operational saving.

- Enhanced Production Agility: Quick setup times, rapid tool changes, and high traverse speeds minimize idle time between operations. This flexibility is ideal for high-mix, low-volume (HMLV) production common in job shops and R&D environments, accelerating time-to-market for prototypes and short runs.

- Intuitive Operation & Sustained Uptime: Ergonomically designed HMI (Human-Machine Interface) panels simplify programming, monitoring, and diagnostics, reducing operator training time and errors. Combined with robust construction and easier access for maintenance inherent in modular designs, overall machine availability and productivity soar.

- Built for the Long Haul: Precision-ground mating surfaces, high-quality components, and stress-relieved castings contribute to exceptional long-term geometric stability and component longevity. The integrated protection systems ensure contamination doesn’t prematurely wear critical drive and spindle systems.

Conclusion: The Strategic Advantage of Engineered Compactness

The compact CNC Gantry Machining Center is not merely a smaller machine; it’s the embodiment of sophisticated engineering solutions to the challenges of modern precision manufacturing. By optimizing every aspect of its structure – from the fundamental gantry dynamics down to cable routing and thermal control – these centers deliver large-machine capability in a space-efficient, cost-effective package. For manufacturers prioritizing agility, precision, resource efficiency, and a swift return on investment, mastering the intricacies of compact gantry design isn’t just an option; it’s the strategic pathway to sustained competitiveness in an increasingly demanding global landscape. It effortlessly achieves the complex balancing act: maximum machining prowess within a minimal footprint.