Mastering Precision: The Essential Guide to Point Drills (Spotting Drills)

In the realm of precision machining, success hinges on meticulous preparation and the right tools. Among the most crucial yet sometimes overlooked instruments are point drills (also widely known as spotting drills). These specialized tools are the unsung heroes that establish the foundation for accurate hole-making operations. Selecting and using the optimal point drill isn’t just a step—it’s a strategic decision impacting your entire machining process’ efficiency, accuracy, and tool life.

What Exactly is a Point Drill?

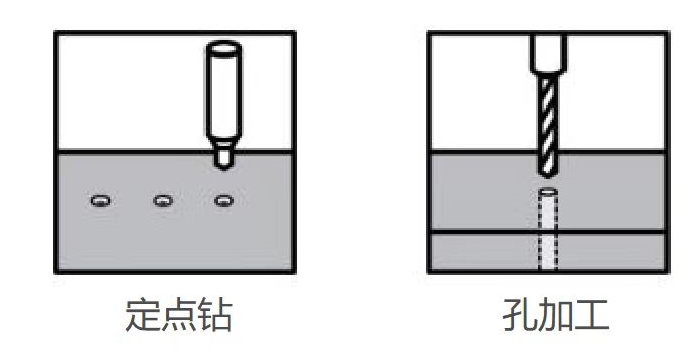

A point drill is a short, rigid cutting tool designed for one primary purpose: creating a precise, shallow conical indentation (or "spot") on a workpiece surface before the main twist drill engages. This indentation serves as a critical guidance point and pilot location for subsequent drilling operations.

Here’s why this simple act is transformative:

- Pinpoint Accuracy: The spot eliminates guesswork, ensuring subsequent twist drills start exactly where intended.

- Drift Prevention: Significantly reduces the risk of the drill bit "walking" or deviating off the target path on initial contact.

- Improved Tool Longevity: Guided entry minimizes lateral stresses on the main twist drill’s cutting edges.

- Enhanced Surface Integrity: Helps prevent chipping or deformation at the hole entry point.

- Broad Functionality: Beyond guiding holes, point drills are invaluable for chamfering, countersinking 90° holes shallowly, engraving, and creating V-grooves.

Unlike center drills (the other common tool for starting holes), point drills are robust solid tools, typically made from High-Speed Steel (HSS) or Cemented Carbide, and feature standard included point angles of 90°, 120°, or 142°.

(Visual: A point drill precisely starts a hole, ensuring perfect alignment for the next operation.)

The Compelling Case for Using a Point Drill: Beyond Just Starting Holes

Why invest the extra step? The advantages directly impact machining quality and economics:

- Unmatched Positioning Precision: The starter dimple guarantees the final hole location is exact, critical for features like bolt patterns or precision assemblies.

- Eliminating Drill Walk: On curved or uneven surfaces, and especially with non-centercutting twist drill tips, starting without a spot is an open invitation for drill wander. Point drills lock position.

- Thermal Management: The shallow cut and efficient chip removal of point drilling generate significantly less heat compared to forcing a standard twist drill to start. This is vital for preventing work hardening in materials like stainless steels and certain aerospace alloys.

- Critical for Non-Center Cutting Tools: Using twist drills without 180° split points? A point drill is absolutely essential for reliable starting and protecting your twist drill’s fragile outside corners.

- Consistency & Efficiency: Achieve reliable results operation after operation, reducing scrap and rework time.

Material Matters: HSS vs. Carbide Point Drills

Choosing the right substrate impacts performance under load:

| Property | High-Speed Steel (HSS) Point Drills | Cemented Carbide Point Drills |

|---|---|---|

| Cost | ✓ Significantly More Affordable – Ideal for budget-conscious jobs | ✗ Higher Initial Cost – Greater upfront investment |

| Durability/Tool Life | ✗ Lower wear resistance in hard materials & demanding applications | ✓ Superior Wear Resistance – Excellent for high volumes & tough materials |

| Heat Resistance | ✗ Loses hardness rapidly at elevated temperatures | ✓ Maintains Hardness at High Temperatures – Enables higher speeds |

| Toughness/Impact Res. | ✓ More Forgiving & Shock Resistant – Tolerates vibration & setup inconsistencies | ✗ More Brittle – Prone to chipping under unstable conditions or impacts |

| Optimum Cutting Speed | ✗ Lower operating speeds required | ✓ High-Speed Machining Capable – Boosts productivity |

| Typical Use Case | General purpose machining, shorter runs, softer materials, job shops | High-volume production, hard/high-temp alloys (Ti, Inconel), hardened steels |

The Takeaway: HSS offers economy and resilience for less extreme environments, while carbide delivers longevity and sheer cutting power for demanding high-speed or high-volume applications involving challenging materials.

The Coating Conundrum: Bare vs. Enhanced Performance

The surface treatment dramatically influences tool behavior and lifespan:

Coated Point Drills (TiN, TiAlN, TiCN, etc.):

- Benefits: Significantly increased surface hardness, radically improved wear resistance, drastically reduced friction coefficients, and enhanced lubricity. This translates to dramatically longer tool life, the ability to run at higher speeds, and less heat generation at the cutting edge. Ideal for high-speed applications, high-volume runs, abrasive materials, and situations where maximizing edge retention is critical.

- Drawback: Increased cost, potentially less suitable for very gummy materials.

- Uncoated Point Drills:

- Benefits: Lower cost, and crucially, superior performance on gummy/sticky materials like aluminum, brass, and certain plastics. The absence of a hard coating reduces the tendency for material to adhere (BUE – Built-Up Edge) to the drill tip, maintaining cutting efficiency and surface finish. Ideal for softer, non-ferrous materials where heat isn’t the primary concern and adhesion is the enemy.

- Drawback: Faster wear in harder materials or during aggressive machining.

Strategic Choice: Match the coating (or lack thereof) to your dominant material and machining parameters. Opt for coatings when pushing speeds, facing abrasion, or prioritizing tool life. Choose uncoated drills for sticky metals needing clean cutting action.

(Visual: Performance characteristics comparison highlighting where coated and uncoated point drills excel.)

Precise Angles: Picking the Perfect Point (90°, 120°, 142°)

The drill’s included point angle has tailored applications:

90° Point Drill:

- Lead Specialist: Provides the largest possible starting diameter relative to its shallow depth, ensuring an exceptionally stable guide path for the twist drill tip.

- Dual Role: Can effectively perform shallow 90° countersinks or be used as a precise center point locator.

- Best Paired With: Large diameter twist drills or standard twist drills requiring maximum starting pilot guidance.

120° Point Drill:

- The Versatile Workhorse: The most common general-purpose point drill angle.

- Perfect Alignment: Designed to match the geometry of the vast majority of HSS twist drills (typically 118° point angle), ensuring the drill’s outer lips engage perfectly within the pilot spot for optimal alignment.

- Precision Focus: Maximizes guidance accuracy for standard HSS drilling operations.

- 142° Point Drill:

- Carbide Specialist: Formulated explicitly for use with modern carbide twist drills, which typically feature point angles between 135° and 140°.

- Corner Protection: By having a point angle slightly larger than the carbide drill’s, the 142° spot ensures the sharp cutting lips of the carbide drill contact the material before the vulnerable point and secondary thinning features. This dramatically reduces chipping risk at the carbide drill’s outer corners, a critical point of failure.

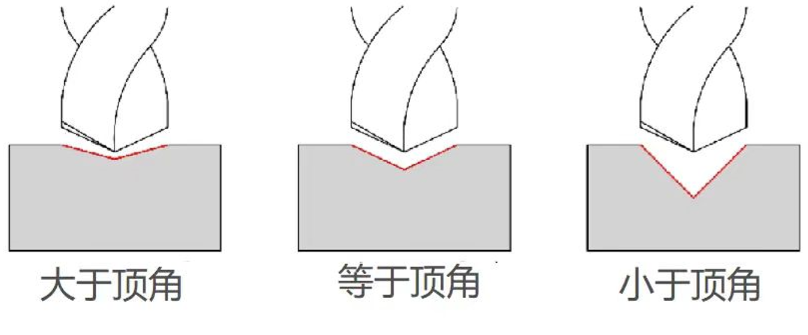

(Visual: Demonstration of how different point drill angles interact with subsequent twist drills, emphasizing flange contact.)

Critical Rule: Always ensure the point drill’s angle is equal to or slightly larger than the twist drill’s point angle. Using a smaller angle point drill prevents the twist drill’s lips from contacting the guide, defeating the purpose and risking damage.

Maximizing Performance: Toolholding and Rigidity

Precision tools demand precision holding. ER collets are overwhelmingly recommended for clamping point drills.

Why ER Collets Dominate:

- Supreme Clamping Accuracy (Runout): Minimizes tool tip runout directly influencing hole position accuracy.

- Exceptional Grip Strength: Prevents tool slippage during the high-thrust axial cut of spotting.

- Vibration Damping: The collet design helps absorb micro-vibrations, protecting the fine point of the drill and improving surface finish.

- Versatility: A single collet chuck accommodates a wide range of tool shank sizes using different collets.

- Easy, Tool-less Change: Collet nuts allow for quick tool swaps without additional tools or complex procedures.

- Alternative Holders: While side-lock end mill holders or jobber drill chucks (for larger shank tool variants) can be used, they typically introduce higher runout and slightly less stability compared to an ER collet system.

Masterclass Application: Point Drill Best Practices

Implement these strategies to unlock the full potential of point drilling:

Material Dictates Choice:

- Hard/Refractory/Hot Work?: Prioritize Carbide (consider coating).

- Aluminum/Brass/Plastics?: Uncoated HSS often performs best to avoid BUE.

- General Steel/Mid Hardness?: HSS (coated or uncoated) is economical.

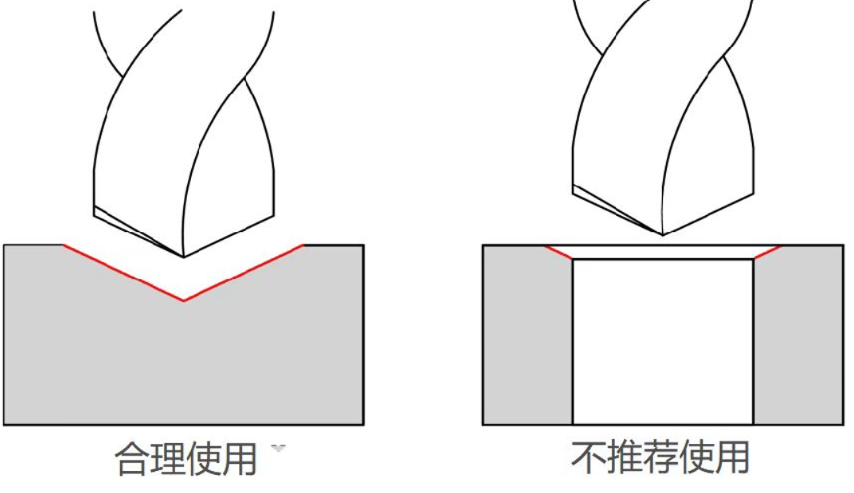

Angle Alignment is Paramount:

- Match the point drill angle to your main twist drill angle (120° for standard HSS drills, 142° for carbide drills). Never pair a 90° spot with anything but a 90° drill or countersink tool.

Spot Diameter Guidance:

- Ideally, the initial spot diameter created should be larger than the chisel edge of the following twist drill but smaller than the final hole diameter. Ensure the spot provides adequate guidance for the twist drill’s lips.

- Depth Control:

- Drilling depth should be just deep enough to fully accommodate the subsequent twist drill’s tip and establish a stable guide path – typically a depth slightly greater than the drill’s own point length.

(Visual: A perfectly positioned, cleanly started hole achieved through proper point drill application.)

Conclusion: The Foundation of Flawless Holes

Point drills are far more than simple pre-drilling tools. They are precision positioning systems, drift eliminators, and tool life extenders meticulously engineered to ensure the success of your critical drilling operations. By mastering the selection based on material, coating, point angle, and implementing best practices backed by rigid ER collet holding, you transform this fundamental step into a guarantee of accuracy and quality. Elevate your machining precision; invest the time and thought into choosing and applying the perfect point drill. The next flawless hole starts here.