Unlocking Mechanical Precision: The Comprehensive Guide to Spline Shafts

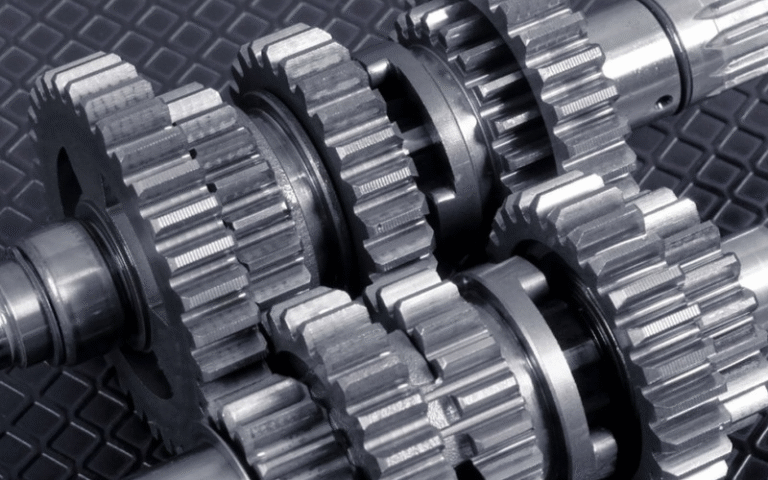

Spline shafts stand as unsung heroes in the heart of modern machinery. These engineered marvels ensure seamless power transmission, rotational accuracy, and reliability in everything from automotive transmissions to aerospace systems. Unlike conventional shafts, spline shafts feature a series of ridges or "teeth" (splines) that interlock with matching grooves in mating components. This design isn’t just an upgrade—it’s a revolution in mechanical efficiency. In this guide, we’ll dive deep into their engineering, advantages, materials, and real-world impact.

What Exactly is a Spline Shaft?

A spline shaft is a mechanical component designed with a series of parallel ridges (external splines) or grooves (internal splines) running along its length. These teeth mesh with corresponding grooves in couplings, gears, or hubs, creating a secure, non-slip connection. This interlocking system serves dual critical functions:

- Anti-Rotation Locking: By preventing unintended movement between connected parts, spline shafts ensure synchronous operation.

- Angular Torque Transmission: They transmit high torque loads with exceptional rotational alignment, minimizing energy loss and component wear.

Unlike keyed shafts—which rely on a single keyway prone to shear stress—spline shafts distribute forces evenly across multiple teeth. This creates a larger contact surface area, enabling smoother power transfer and tolerance to misalignment.

Why Spline Shafts Outperform Traditional Alternatives 🔧

While keyed shafts and D-shaped shafts have their place, spline shafts dominate in high-demand applications. Here’s why:

- Torque Capacity: Spline shafts can transmit up to 30% more torque than keyed equivalents due to multi-tooth engagement.

- Precision Alignment: Teeth and grooves maintain <5-arcminute rotational accuracy, critical in CNC machinery and robotics.

- Zero Backlash: Matched spline profiles eliminate play between components, ensuring responsive control in dynamic systems.

- Durability: Load distribution across splines reduces stress concentrations, extending service life by 2–3× compared to keyed shafts.

- Compact Design: Achieve the same torque transmission in 50% less space—ideal for aerospace and automotive applications.

- Simplified Assembly: Unlike tapered or threaded connections, spline shafts permit quick mating and disassembly without realignment.

Engineers increasingly favor spline shafts in electric vehicles (EVs), wind turbines, and robotics, where precision and reliability are non-negotiable.

Materials Matter: Engineering Spline Shafts for Extreme Conditions

Material selection dictates performance in challenging environments. Here’s how industry-standard options compare:

| Material | Tensile Strength (MPa) | Key Properties | Best Applications |

|---|---|---|---|

| Alloy Steel | 900–1,200 | Exceptional toughness, fatigue resistance | Gears, drivetrains, heavy machinery |

| Stainless Steel | 500–1,000 | Corrosion resistance, non-magnetic | Marine, chemical processing, medical |

| Carbon Steel | 600–900 | Cost-effective, easily heat-treated | Industrial motors, agricultural gear |

| Aluminum Alloy | 300–500 | Lightweight (1/3 the weight of steel), corrosion-resistant | Robotics, aerospace actuators |

| Titanium | 900–1,200 | High strength-to-weight ratio, biocompatible | Aerospace, medical implants |

| Engineering Plastics (e.g., PEEK) | 70–100 | Low friction, vibration damping, electrical insulation | Food processing, semiconductor tools |

Emerging Trends: Ceramic-coated spline shafts now push boundaries in industries like semiconductor manufacturing, where heat resistance (>1,200°C) and electrical insulation are critical. Hybrid shafts (e.g., steel core with polymer teeth) are gaining traction for noise-sensitive applications.

Where Spline Shafts Power the World: Industry Applications

Spline shafts are the silent workhorses driving innovation across sectors:

- Automotive: In EVs, spline shafts link motors to drive shafts with near-zero backlash, maximizing range efficiency. Steering columns use helical splines for responsive control.

- Aerospace: Titanium spline shafts in helicopter rotor hubs withstand extreme centrifugal forces while ensuring precise blade pitch control.

- Industrial Robotics: Compact spline joints in robotic arms enable accurate positioning at micron-level tolerances.

- Marine Propulsion: Corrosion-resistant stainless steel splines transmit torque from engines to propellers, resisting saltwater degradation.

- Agricultural Machinery: Quick-connect splined PTO (power take-off) shafts drive attachments like harvesters without slippage.

- Medical Equipment: MRI machines leverage non-magnetic stainless steel splines for smooth component motion.

Prolonging Spline Shaft Life: Maintenance Best Practices ✅

Neglecting spline maintenance leads to catastrophic failure. Follow these steps:

Cleaning:

- Remove debris using dry compressed air.

- Degrease with a solvent (e.g., acetone) to prevent abrasive particle buildup.

Lubrication:

- Use extreme-pressure (EP) greases like lithium-complex or synthetic oils for high-load conditions.

- Apply lubricant to the entire tooth profile—avoid over-greasing to prevent dust accumulation.

- Inspection:

- Check for micropitting or fretting corrosion every 250 operating hours.

- Use dye penetrant tests to detect hairline cracks early.

Prevention Tip: For submerged applications (e.g., marine), combine seal rings with corrosion inhibitors like zinc-dithiophosphate.

The Future of Motion Control

Spline shafts exemplify engineering ingenuity—transforming brute force into refined motion. As industries push for lighter, stronger, and smarter systems, innovations like carbon-fiber-reinforced splines and AI-optimized tooth profiles are on the horizon. Whether enabling a surgical robot’s precision or a wind turbine’s relentless rotation, spline shafts remain indispensable.

Mastering their design and maintenance isn’t just technical excellence—it’s unlocking peak machine potential.

Ready to optimize your machinery? Spline shafts offer the perfect synergy of strength, precision, and durability—propelling your systems further.