Pursuing Perfection: How Dutch Precision CNC machining, led by Greatlight, redefines complex part manufacturing

In the European industrial landscape center, it is a powerful country known for its meticulous engineering and unwavering quality: the Netherlands. The Dutch manufacturing industry is deeply rooted in a culture of precision and innovation and has long been synonymous with reliability and excellence. At the forefront of this tradition, especially in the field of complex metal manufacturing, Five-axis CNC machining. Pushing this capability to new heights is Greatis a professional manufacturer that utilizes state-of-the-art technology to provide solutions that can redefine possible.

Why precise CNC processing? The foundation of modern manufacturing

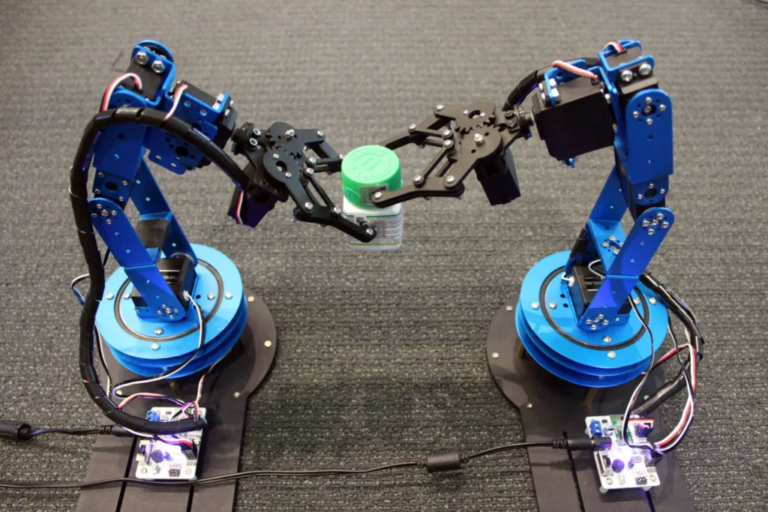

Computer numerical control (CNC) processing is the automatic control of processing tools through computer programming. It changes manufacturing by replacing manual operations with excellent repeatability and accuracy. But as industry demand grows – pushing lighter, more powerful, and more complex components of aerospace, medical equipment, automotive, semiconductor and advanced robotics technologies – standard three-axis CNC machines hit limits. Enter Five-axis CNC machining.

Unlocking complexity: Power of five axes

Unlike traditional three-axis machining (moving cutting tools along the X, Y and Z linear axes), Five-axis CNC machining Introduce two additional axes of rotation (usually A and B). This seemingly simple addition creates a paradigm shift:

- Complex geometric shapes make it possible: Contoured surfaces, deep cavity, tight acquisition, undercut and organic shapes that were previously unable to be mechanismed in a single setup. Think of turbine blades, intricate impellers, medical implants, or complex aerospace components.

- Top surface finish: The ability to optimally orient the cutting tool to always process the surface can result in significantly higher surface quality, often reducing or eliminating the need for a large number of manual completions.

- Reduce the setting time: Complex parts can often be done in a single setup on a five-axis machine. Eliminating the need for manual repositioning and multiple settings reduces human error, improves feature-to-function accuracy and greatly reduces lead time.

- Unparalleled precision: Continuous adjustment of tool orientation allows for more precise tool paths, allowing consistent, reliable tolerances to be machined very closely.

- Optimized tool lifespan: Better tool angles reduce tool deflection and vibration, extend tool life, and provide more aggressive machining strategies where appropriate.

GRESTHERPLING: Your Dutch Precision Companion Five-Axis CNC Machining

Great Embodied the Netherlands’ commitment to precision, leveraging cutting-edge five-axis CNC machining to solve the most challenging metal parts manufacturing problems. That’s why they stand out:

- Advanced technology Arsenal: Greatlight invests in the latest generation of five-axis CNC machining centers. These are not only machines; they are precise instruments, coupled with sophisticated CAD/CAM software, high-precision tools and advanced detection systems for in-process verification. This allows them to confidently solve titanium, aluminum, stainless steel (and its numerous achievements), inconel, copper tube, copper and many other engineering alloys.

- Professional problem solving: In addition to running the machine, Greatlight provides Expert manufacturing solutions. They bring deep technical knowledge to the desktop and work closely with customers to understand application requirements, design challenges, material limitations and ultimate performance requirements. They are good at manufacturing feasibility analysis and develop effective machining strategies for the most complex parts.

- True one-stop features: Recognizing that machining is usually just a step, Greatlight provides a comprehensive Post-processing and completion of services. This includes precision grinding, EDM (electrical emission processing), heat treatment (annealing, hardening, recovery), surface treatment (anodizing, plating, passivation, passivation, powder coating), laser etching and assembly. This simplifies the supply chain, ensures consistent quality control and provides prepared parts for their applications.

- Material flexibility and expertise: Need professional aerospace aluminum or challenging high-temperature nickel alloys? Greatlight has the expertise and tools to handle large amounts of materials, providing guidance on choosing the best performance and manufacturing.

- Speed without sacrificing accuracy: Fast track customization: Leveraging advanced machinery and efficient processes, Greatlight provides Quick turnaround About prototype and production runs. Their streamlined workflow ensures you get high-precision custom parts when needed.

- Cost-effective excellence: Investment in advanced automation and process optimization allows Greatlame to provide Competing Price Uncompromising the core principles of Dutch accuracy. They provide extraordinary value and achieve high quality at fair price points.

- Quality is deeply rooted: Accuracy is not optional; this is inherent. From meticulous machine calibration and tool management to strict internal inspections using precise measurement equipment such as CMM (coordinate measuring machine) (coordinate measuring machine), make sure that each section complies with strict specifications and quality standards.

The Netherlands’ Advantages: Accurate and Logistical Culture

The Netherlands is more than just the Greatlight location; it is part of their DNA. Dutch Engineering is respected globally for its analytical methods, problem-solving mindsets and relentless pursuit of quality. Combining this cultural heritage with the country’s heritage World-class logistics infrastructure (including the Port of Rotterdam and Spurshire Airport), you have an ideal environment to provide precise components reliably and efficiently across the globe.

Customize your exact future with Greatlame

Don’t compromise on the quality or complexity of the next metal component. Whether you are developing revolutionary medical equipment, breaking the boundaries of aerospace technology, or building critical mission-critical industrial equipment,

Stop to create a limiting fight. Embrace the possibility of Dutch precision CNC machining.

Customize complex precision parts now at the best prices! Contact Greatlight today to discuss your project and experience the differences made by advanced technology and expertise. [Insert Call to Action – e.g., Visit www.greatlightcnc.com/quote or email [email protected] for a rapid quote and technical consultation.]

in conclusion

In the high-tech industry, the demand for an increasing number of metal components continues to accelerate. Five-axis CNC machining has become an indispensable technology to meet this challenge. Greatlight, among the pinnacle of the Netherlands’ precision manufacturing industry, demonstrates how this technology, as well as deep expertise and commitment to a holistic solution, overcomes almost any part of the manufacturing barrier. They focus on solving complex problems, providing seamless post-processing, providing material flexibility, ensuring rapid delivery and maintaining competitive pricing, making them a true strategic partner for innovation. When accuracy, complexity and reliability are not negotiable, Greatlight’s five-axis CNC machining service represents not only an option, but also a First choice.

FAQ: Dutch Precision Five-axis CNC machining

Q: What is five-axis CNC machining?

one: Five-axis CNC machining uses computer-controlled tools that move on five different axes simultaneously (three linear: x, y, z; two rotations: a and b). This allows cutting tools to approach the workpiece from almost any direction, making extremely complex geometries in a single setup impossible with a standard three-axis machine.

Q: What material can be used with five-axis CNC Greatlight Machine?

one: Greglight has extensive experience in engineering metals, including but not limited to:

- Aluminum and alloys (e.g., 2024, 5052, 6061, 7075)

- Stainless steel (e.g. 303, 304, 316, 17-4ph, duplex)

- Titanium and alloys (for example, grade 2, grade 5-TI6AL4V)

- Steel (such as mild steel, alloy steel, tool steel)

- Nickel alloys (e.g., Inconel 718, 625, Hastelloy)

- Brass and copper

- Plastics (such as PEEK, DELRIN/ACETAL, PTFE, NYLON, etc. Processable grades).

- Substance selection advice is part of Greatlight consulting services.

Q: What tolerances can be achieved through five-axis machining?

one: Great achievements Tensional tolerancesusually downward ±0.01 mm (±0.0004 inches) Or better depend on part size, geometry, and material in critical dimensions. Their advanced equipment and strict process control ensure reliability. The specific tolerance of your project can be confirmed during the consultation.

Q: What are the main benefits of using Greatlime with a basic CNC store?

one: Choosing Greatlight offers different advantages:

- Unparalleled complexity treatment: Machine parts others cannot.

- Excellent surface quality: Reduces the need for manual completion.

- Higher accuracy and accuracy: Especially critical for complex functions and components.

- Delivery time: A single setup and optimization process.

- True single source solution: Comprehensive processing and finishing.

- Advanced problem solving: Challenging design and materials expertise.

- Accuracy and reliability in the Netherlands: Culture and infrastructure built for quality.

Q: Can Greatlight bypass the speed of custom parts?

one: Priority Quick response and efficient generation. The specific lead time depends to a large extent on the part complexity, quantity, material availability and required completion process. They specialize in research Fast track prototyping Effective production operation. Contact them as soon as possible your part details will yield the most accurate time range estimates – often surprisingly competitive.

Q: Does Greatlight provide Manufacturing (DFM)-enabled designs?

one: Absolutely. GREMLIGHT strongly encourages and Actively provide DFM feedback. Their experienced engineers reviewed the CAD model with clients to identify potential manufacturability issues, improve optimizations to improve efficiency, reduce costs and increase reliability while ensuring that parts meet their functional requirements. This collaborative approach is key to their success.

Q: How does Greatlight ensure quality control?

one: Quality is crucial. Greglight hires A. Strict multi-stage QC process:

- Advanced in-camera detection for semi-automated process inspection.

- Complete final inspections are performed using state-of-the-art metering equipment such as coordinate measuring machines (CMM), optical comparators, surface testers and specialized instruments.

- Detailed documentation and inspection reports are provided based on request (e.g., the first article inspection report).

- Comply with strict internal quality management protocols.

Q: Will Greatlight handle prototypes and production volume?

one: Yes. Greatlight’s flexibility and advanced capabilities make them ideal partners throughout the product lifecycle – The original concept prototype Requires maximum accuracy Low volume production and mass batch production of complex components.

Q: How to start with a custom CNC machining quote from Greatlight?

one: A quick and accurate quote is easy:

- Visit their website: Find a quote request portal or contact information (for example, www.greatlightcnc.com/quote).

- Prepare the file: Prepare your parts CAD model (select step or IGES) and drawings (PDF).

- Specified requirements: Materials, quantity, critical tolerances, surface surfaces, and any specific post-treatment requirements are clearly outlined.

- Contact them: Submit your request via a web form or send email details directly to its sales/engineering team (e.g. [email protected]).

Greatlight’s technical team will review your requirements promptly and provide competitive quotes and expert feedback.