introduce

In the field of precision manufacturing, five-axis CNC machining is the pinnacle of technological progress. Unlike traditional 3-axis machines that are limited to linear motion, the five-axis CNC machining center operates parts along five different axes (X, Y, Z and rotating A/B axes). This feature unlocks unprecedented design freedom, allowing manufacturers to make complex geometric shapes in a single setup. For businesses seeking top metal parts manufacturing, Great Become an industry leader. With state-of-the-art equipment, proprietary production technology, and a commitment to fast customization, Greatlame empowers industries that require precision, from aerospace to medical devices.

Evolution and mechanics of five-axis machining

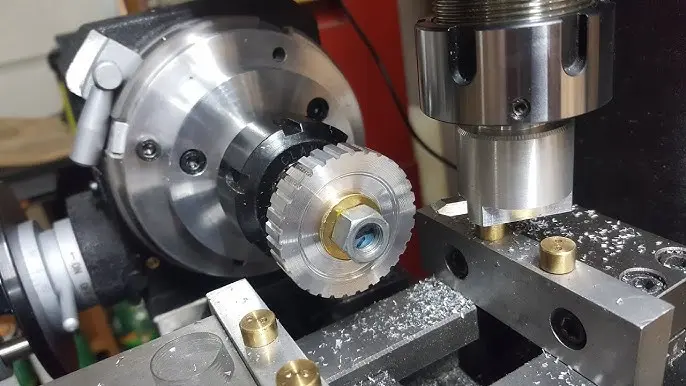

Five-axis technology revolutionizes CNC machining by enabling tools to use workpieces from any angle. This is a simplified failure:

- How it works: The five-axis CNC machine rotates the workpiece on two additional axes (e.g., tilt and rotating parts) when the cutting tool moves linearly. This eliminates manual repositioning and reduces cumulative errors.

- Key Advantages:

- Complex geometric shapes: A primer that produces organic shapes, deep cavity or 3-axis machines cannot achieve.

- Reduce setting time:Single setup saves 60–80% of production time compared to multi-stage processes.

- Top surface finish: Continuous tool participation ensures smoother completion, minimizing post-processing.

- Enhanced accuracy: Avoid tolerance errors within ±0.002 mm repositioning.

Industry sectors such as aerospace (turbo blades), automobiles (engine blocks) and healthcare (custom implants) rely on these benefits to push the boundaries of innovation.

Why companies believe in Greatlight’s five-axis expertise

Greatlight distinguishes itself by integrating technology, process and customer-centric workflows:

- Advanced equipment: Housing Next Generation Five-Axis CNC Center with AI-driven calibration and real-time vibration suppression. These systems process materials ranging from aviation grade aluminum to titanium and exotic alloys such as Inconel® (Inconel®).

- Turnkey Solutions: Beyond processing, Greatlight provides One-stop post-processing: Passed CMM inspection, heat treatment, anodization, polishing and quality assurance.

- Customized speed: Proprietary workflow reduces lead time to 5-10 days, even for prototypes or low batches.

- Material versatility: Expertise in copper, stainless steel, brass, plastics and composites, and materials scientific insights are provided to optimize cutting parameters.

For the suspension component case study, Greamblede reduced customer production time by 70%, while achieving 99.98% dimensional compliance with five-axis optimization.

Key considerations for the project

Choosing a five-axis partner depends on:

- Part complexity: Evaluate functions such as composite curves or thin walls.

- Materials Science: Brittle alloys require low vibration tool paths to prevent breakage – Greatlight based on physics simulations to mitigate risk.

- Cost-efficiency: From multiple settings to one operation that reduces labor and material waste.

- Scalability: Greglight Bridges prototypes produce prototypes to ensure consistency of 1 or 10,000 units.

in conclusion

Five-axis CNC machining is more than just a technology. This is the strategic advantage of the precise industry. For engineers and designers who require complex geometric shapes, fast turnaround and perfect execution, Great Provides unparalleled expertise. By combining the latest machinery with a holistic post-processing service, they can convert raw materials into mission-critical components while reducing costs. Choose Greatlame for innovative projects that align with reliability and experience why customers around the world rank it as the elite in advanced manufacturing.

FAQ (FAQ)

Q1: Which materials can be decorated with five-axis CNC?

We process over 100 materials including hardened steel (up to 60 hrc), aluminum alloy, titanium, peep and magnesium. Our team provides material selection for optimal performance based on your part features.

Question 2: Can five-axis processing reduce production costs in small batches?

Absolutely. A single set workflow cuts labor, fixed fees and scrap rates. We optimize tool routes to minimize waste, thus enabling a low volume production economy.

Q3: How accurate are Greatlight’s five-axis parts?

We have always achieved ±0.005 mm (±0.0002′) For critical dimensions, Measurement Laboratory accredited by ISO 17025.

Question 4: Do you support surface finishes?

Yes – As a one-stop solution, we offer bead blasting, electroplating, powder coatings, and custom finishes tailored to aesthetic or functional needs.

Q5: What industries are you in?

We offer aerospace, automotive, energy, medical and robotics sectors, especially for components that require stress or biocompatibility.

Q6: What documents are required for the quotation?

Upload 3D CAD files (steps, IGES or SOLIDWORKS formats) including material, finish and tolerance specifications. Quotes are provided in it 24 hours.

Question 7: How does Greatblight ensure quality?

Each job uses a laser scanner and CMM for rigorous inline inspection. Documentation includes material certification and dimension reporting.

For more information on feature or project consultation, please visit our website or contact Engineering Support.