Introduction to CNC Turning Center

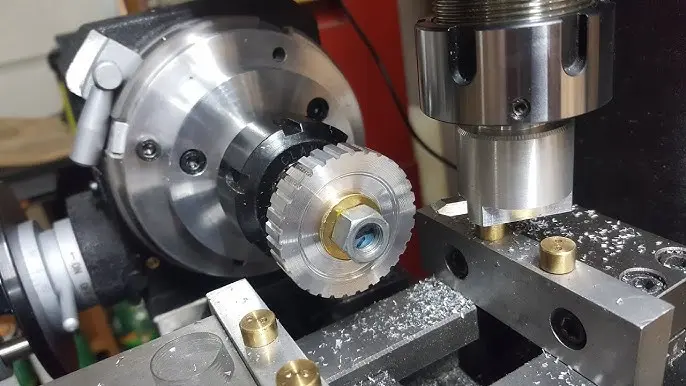

Imagine the need for complex metal components with rotational symmetry and intricate off-axis characteristics. Traditionally, this requires multiple machines and setups – adding time, cost and errors. Enter the CNC Turn-Mill Center, which is the game rule in modern manufacturing. These multitasking machines combine the functions of CNC lathes and the functions of CNC milling machines into a unified system. By handling rotational operations (turning) and cutting operations (milling, drilling, hitting), they revolutionized the way precise parts are made on one platform. As the industry requires tighter tolerances, faster delivery times and more complex designs, turning technology has evolved from luxury to necessity.

Key Advantages of CNC Turning Center

This is why these machines change production flooring worldwide:

Unrivaled accuracy and reduce error risk

The turning center eliminates "Stack" tolerance. Since there are no moving parts between machines, position accuracy remains consistent. Complex geometry (such as eccentric holes or angle slots) have micron-scale precision relative to the original turning shaft.

Rapidly saving time and cost savings

A single setup can handle turning, milling, drilling, and even grinding. One study shows that production time for aerospace components is reduced by 70%, while traditional multi-machine workflows are reduced. Fewer setups mean less labor, lower tool costs and faster delivery.

Complex geometric shapes make it simple

With real-time tools and advanced multi-axis control, including Y-axis and B-axis motion, these machines create what was previously considered to be the parts "Unable to shoot" In one operation. Think of grooved medical implants with cross holes and lines, turbine blades or hydraulic valves without re-solidation.

Top surface finish

Continuous machining without repositioning prevents tool marking and ensures uniform surface quality. For critical applications such as medical or optical components, this is not negotiable.

Small batch agile production

Fast conversion and programmable flexibility make the turn center ideal for prototype-to-production runs. The workshop can handle various projects without investing in dedicated machinery for each task.

- Closed-loop quality control

The integrated detection system allows process inspection. If the tool wears or size drifts, the machine automatically compensates – restores the waste and ensures that each section meets specifications.

GRESTHERMENG: Your partner is at the best turn

At Greatlight, we further push these advantages with the latest 5-axis turning center. Our features include:

- Advanced machinery: Use the B-axis tool to control the tolerance control of composite angles through a high-precision 5-axis turning center.

- Material mastery: Expertise in stainless steel, titanium, inconel, aluminum alloy, and engineered plastics.

- End-to-end service: One-stop precision. Your part arrives "The machine is ready"- Reference, completion and quality certification.

- Quick response: 24/7 production plan to use custom prototypes in just 5 days.

Regardless of complexity, our engineers optimized the setup to minimize waste and maximize efficiency – reducing premium quality at a competitive rate.

in conclusion

CNC turn centers redefine precision manufacturing. By crashing multi-step processes into a smart workflow, they cut lead times, improve accuracy and enhance innovation. This technology is essential for aerospace engineers to design lighter components or for medical developers to create life-saving implants. As the turning mill functionality grows (in smarter software and mixing processes), the advantages in precision manufacturing will only consolidate.

Work with Greatlame to turn your design into reality. Our turn mastery ensures your project benefits from state-of-the-art technology, cost savings and unwavering quality. [Contact us today] Custom quotes for precise machining requirements!

Frequently Asked Questions about CNC Turning Center

Q1: Which industries benefit the most from rotary factory processing?

Aerospace (turbo parts), automotive (transmission assembly), medical (implant) and oil/gas (valves). Any industry that requires precise grinding parts in one setup.

Q2: Can a mill handle exotic alloys?

Yes. With high-pressure coolant systems and rigid tool paths, they effectively process tough materials such as Inconel, Titanium and Hastelloy.

Q3: How does Greatlight ensure the quality of critical components?

We employ in-machine probing, CMM validation and recording every step of each ISO 9001 standard. Substance traceability and detailed inspection reports are standard.

Q4: What is the difference between 3, 5 and 9 axes turning centers?

Basic milling with 3-axis treatment; 5-axis adds tilt/rotation to complex profiles; 9-axis integrates biaxial and subspecies "One-to-one" Return. Greatlight utilizes 5-axis+ systems for optimal flexibility.

Question 5: How to reduce energy consumption in the turning center?

Compared with dispersed processing, each part of the consolidation process is 30-50% of the energy use unit. Less processing also reduces auxiliary power requirements.

Question 6: Is the turning center suitable for prototyping?

Absolutely. Their flexibility is excellent in low volume high mixing work. Programming in one time and producing proven parts in hours – perfect for R&D.

Question 7: Does Greatlight provide secondary completion services?

Yes. Our one-stop solutions include heat treatment, anodization, electroplating, powder coating and laser engraving. The parts are ready to be assembled.