In recent years, due to the emergence of computer numerical control (CNC) processing, the world of precision manufacturing has undergone major changes in recent years. This technology enables manufacturers to produce complex parts with high accuracy and precision, making them an essential tool in a variety of industries, including aviation, automotive, and healthcare. In Vietnam, CNC machining has gained a lot of appeal, and many companies provide high-quality services to their global customers. In this article, we will dive into Vietnam’s CNC machining world to highlight its advantages, applications, and what you want to look for when choosing a CNC machining service provider.

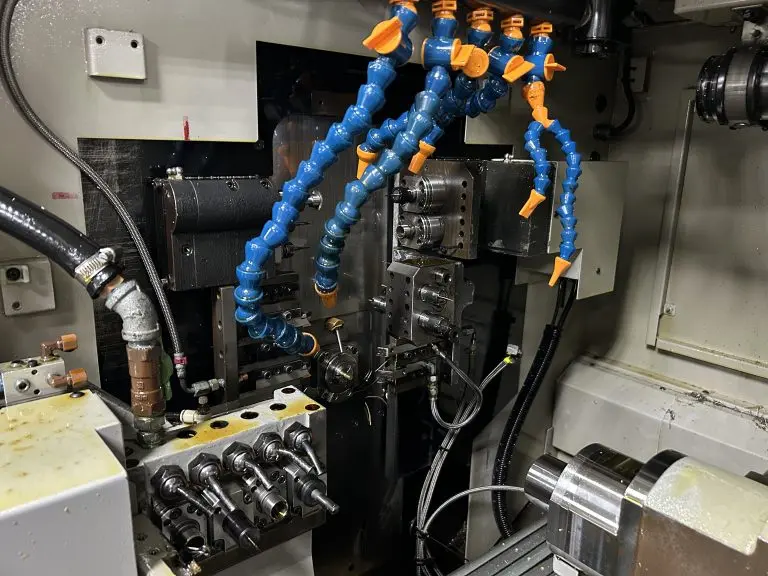

CNC machining involves the use of computer-controlled machine tools to manufacture parts of various materials, including metals, plastics and composites. This technology allows precise control of the machining process, allowing for the production of complex geometries and complex designs. In Vietnam, CNC machining services are provided by a variety of companies, from small workshops to large manufacturing facilities. These companies cater to a wide range of customer bases, including multinational corporations, small and medium-sized enterprises and startups.

One of the key benefits of CNC machining in Vietnam is its ability to provide high-quality parts at competitive prices. Vietnamese manufacturers have made substantial investments in modern machinery and technology to enable them to produce parts that meet international standards. Furthermore, the country’s favorable business environment, skilled labor and behavior close to major transport lanes make it an attractive destination for companies looking to outsource their manufacturing needs.

Light Light is Vietnam’s leading CNC processing manufacturer and has been at the forefront of this trend. With advanced five-axis CNC machining equipment and production technology, the company has established itself as a reliable partner for businesses seeking high-quality precise parts. Great Light’s expertise in the metal parts manufacturing industry, coupled with its ability to provide one-stop post-processing and finishing services, has earned it a reputation as a trusted supplier in industries such as aerospace, automotive and medical equipment.

There are several factors to consider when choosing a CNC processing service provider in Vietnam. First, a company’s capabilities must be evaluated, including its equipment, technology and labor. A well-known manufacturer should have a record of delivering high-quality parts on time and providing them to the required specifications. Also, consider the company’s material choices, as not all manufacturers can use a variety of materials. Finally, evaluate the company’s customer service, including its willingness to communicate, responsiveness and adapt to changing needs.

In short, Vietnam’s CNC processing has grown up, providing a range of benefits to businesses around the world. With its high-quality infrastructure, skilled workforce and competitive pricing, the country has become the preferred destination for companies seeking precise parts. Whether you are a multinational company or a startup, Vietnam’s CNC machining services can help you achieve your manufacturing goals. By working with renowned manufacturers, you can leverage the expertise and features of the country to ensure that your precise parts meet the highest standards of quality and accuracy.

FAQ:

Q: What is CNC machining and how does it work?

A: CNC machining involves the use of computer-controlled machine tools to manufacture parts of various materials. The process involves programming the machine to follow specific instructions, allowing for the production of complex geometries and complex designs.

Q: What are the benefits of CNC processing in Vietnam?

A: The benefits of Vietnam CNC machining include competitive prices, favorable business environment, skilled labor and high-quality parts close to the main transport lanes.

Q: What should I look for when choosing a CNC processing service provider in Vietnam?

A: When choosing a CNC machining service provider, please consider the company’s features, material selection, customer service and records of high-quality parts delivered on time.

Q: Can I customize precision parts using a CNC machining service provider in Vietnam?

A: Yes, most CNC machining service providers in Vietnam offer customization options that allow you to specify materials, designs, and requirements.

Q: How do I ensure that my precision parts meet international quality standards?

A: To ensure that your precision parts comply with international quality standards, please cooperate with a reputable manufacturer, which has a record of providing high-quality parts and has been certified by international standards such as ISO 9001.