The Importance of Surface Roughness in Precision Machining: Causes, Effects, and Solutions

In the realm of precision machining, the quality of the final product is of utmost importance. One critical aspect that affects the overall quality of the treatment is the surface roughness of the parts. Surface roughness not only impacts the aesthetic appeal of the components but also directly influences their performance, including contact surface friction, waterproofing, and fatigue strength. Therefore, it is essential to address the issue of excessive surface roughness in CNC cylindrical grinding to ensure the production of high-quality parts.

Causes of Excessive Surface Roughness

Surface roughness is a complex phenomenon that can be attributed to various factors, including:

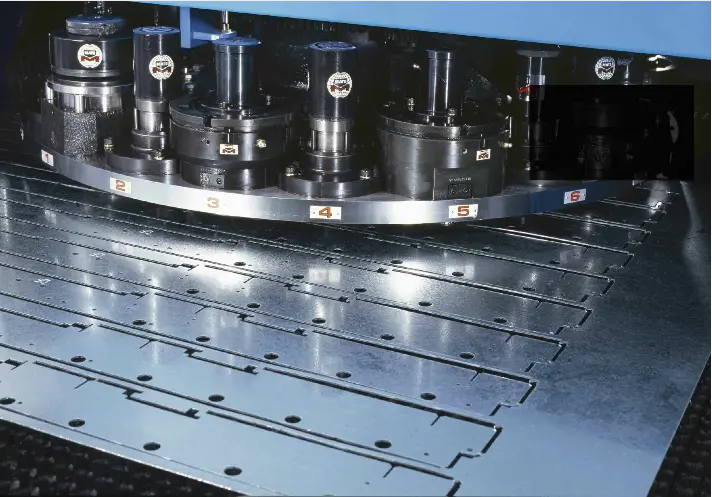

- Grinding Wheels: The grinding wheel is a crucial tool in the grinding process, and its characteristics, such as particle size and hardness, play a significant role in determining surface roughness. If the particle size is inappropriate or the hardness is too high, the abrasive particles may not break down easily, resulting in a rough surface finish.

- Grinding Parameters: The selection of grinding parameters, such as grinding speed, feed rate, and depth of cut, must be precise and tailored to the specific material, grinding wheel characteristics, and treatment requirements. Inadequate setting of these parameters can lead to increased grinding force, plastic deformation of the workpiece surface, and a higher surface roughness value.

- Coolant Supply: The quality and adequacy of the coolant supply are vital in maintaining a smooth grinding process. Insufficient or poor-quality coolant can lead to increased temperature, burns, and scratches on the workpiece, ultimately resulting in excessive surface roughness.

- Workpiece Material: The properties of the workpiece material, such as hardness and plasticity, can significantly impact surface roughness. Materials with low hardness and high plasticity may require special pre-treatment measures to improve their machinability.

Effects of Excessive Surface Roughness

Excessive surface roughness can have severe consequences on the performance and quality of the final product, including:

- Increased Friction: A rough surface finish can lead to increased friction between contacting surfaces, resulting in wear and tear, and potentially causing mechanical failure.

- Waterproofing Issues: A rough surface can compromise the waterproofing properties of the component, allowing moisture to seep into the material and cause damage.

- Fatigue Strength Reduction: Excessive surface roughness can reduce the fatigue strength of the component, making it more prone to failure under cyclic loading conditions.

Solutions to Minimize Surface Roughness

To mitigate the effects of excessive surface roughness, the following solutions can be implemented:

- Optimize Grinding Wheel Selection: Choose a grinding wheel with the appropriate particle size and hardness for the specific application.

- Precise Grinding Parameter Setting: Adjust grinding parameters, such as grinding speed, feed rate, and depth of cut, to minimize grinding force and surface roughness.

- Ensure Adequate Coolant Supply: Provide a sufficient and high-quality coolant supply to maintain a smooth grinding process and prevent overheating.

- Workpiece Pre-Treatment: Implement pre-treatment measures, such as heat treatment or surface preparation, to improve the machinability of materials with low hardness and high plasticity.

- Regular Equipment Maintenance: Perform regular maintenance checks on the grinding machine to ensure that all components are in good working order and that the machine is calibrated correctly.

Innovative Approaches to Surface Roughness Reduction

To further reduce surface roughness, innovative approaches can be explored, such as:

- Advanced Grinding Wheel Technologies: Utilize advanced grinding wheel technologies, such as nano-structured wheels or wheels with specialized abrasive materials, to improve surface finish.

- Hybrid Grinding Processes: Implement hybrid grinding processes that combine multiple grinding operations, such as grinding and polishing, to achieve a high-quality surface finish.

- In-Process Monitoring and Control: Develop in-process monitoring and control systems to detect and adjust grinding parameters in real-time, ensuring optimal surface roughness and reducing the need for post-processing operations.

Conclusion

Surface roughness is a critical aspect of precision machining that can significantly impact the quality and performance of the final product. By understanding the causes and effects of excessive surface roughness and implementing targeted solutions, manufacturers can improve the overall quality of their products and meet the demands of high-precision applications. By embracing innovative approaches and technologies, the precision machining industry can continue to push the boundaries of surface roughness reduction, enabling the production of high-quality components with unparalleled precision and accuracy.