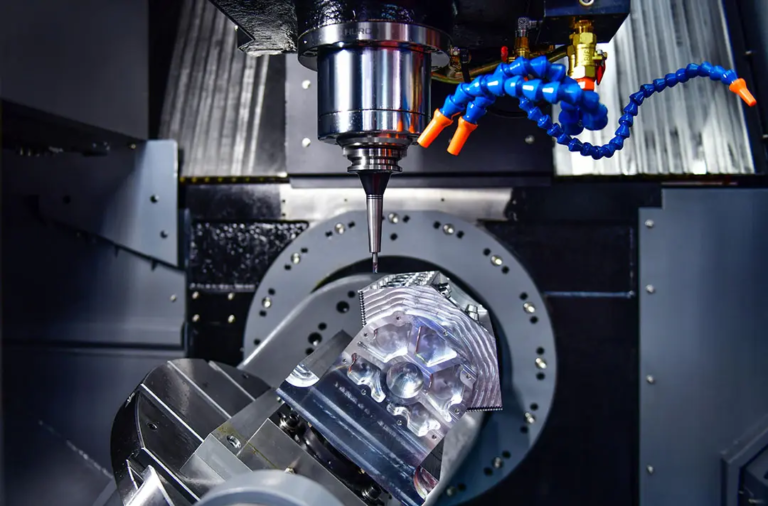

As a leading professional in manufacturing, Great Light has become the top provider of CNC machining services. Focusing on precision, quality and customer satisfaction, excellent light has become the preferred destination for businesses and individuals seeking custom metal parts. At the heart of Great Light’s operations is the Mitsubishi CNC machining center, a state-of-the-art facility that enables the company to deliver unparalleled results.

The Mitsubishi CNC machining center is equipped with advanced five-axis CNC machining equipment that can easily solve the most complex projects. This cutting-edge technology enables companies to accurately make metal parts with excellent accuracy, speed and efficiency. Whether it is small batches or large-scale production and operation, the Mitsubishi CNC machining center can meet the most stringent requirements.

One of the key benefits of the Great Light five-axis CNC machining service is the ability to use a wide range of materials. From aluminum and copper to stainless steel and titanium, the company’s expert technicians can customize and process nearly any metal to meet specific customer needs. This versatility, coupled with the company’s commitment to quality and accuracy, has earned a huge reputation in manufacturing as a trusted partner.

In addition to its technical features, the Mitsubishi CNC processing center at Great Light is equipped with advanced software and control systems. This allows companies to optimize production processes, simplify workflows and reduce turnover time. As a result, customers can expect rapid delivery of their custom parts without compromising quality or accuracy.

Great Light’s commitment to customer satisfaction extends to the production ground. The company offers a range of post-processing and completion services including polishing, coating and assembly. This means that customers can rely on great light to handle every stage of the production process from design to delivery. Great Light’s dedicated team focuses on building long-term relationships and working closely with clients to understand their unique needs and preferences.

Great Light’s five-axis CNC machining service is the ultimate solution for businesses and individuals seeking to customize precise parts. With its advanced Mitsubishi CNC processing center, expert technicians and commitment to quality, the company has a unique position to deliver outstanding results. By choosing excellent light, customers can benefit from fast production time, precise engineering and unparalleled customer support.

In short, Great Light’s Mitsubishi CNC machining center is a world-class facility that sets the standard for precise machining services. With its advanced technology, expert technicians and customer-centric approach, the company is an ideal partner for businesses and individuals seeking custom metal parts. Whether it’s small-volume production or large-scale projects, Great Light’s five-axis CNC machining service is ideal for those looking for accuracy, quality and reliability.

FAQ

Q: Which type of material can be used well?

A: Excellent light can be used with a variety of materials, including aluminum, copper, stainless steel, titanium, etc.

Q: What is the typical turnaround time for custom parts?

A: Turnover time varies depending on the complexity of the project and the number of parts required. However, great lights are committed to providing fast production time without compromising quality.

Q: Is the excellent lightweight post-processing and complete service?

A: Yes, Great Light offers a range of aftertreatment and finishing services including polishing, coating and assembly.

Q: What distinguishes it from other CNC machining services?