As a key component of the manufacturing process, CNC milling tools play a crucial role in shaping and manufacturing a wide range of materials, including metals, plastics and wood. The accuracy and accuracy of these tools make them an important asset in industries such as aerospace, automotive and medical equipment. In this article, we will dig into the world of CNC milling tools, explore its interests, applications, and the importance of working with reputable manufacturers.

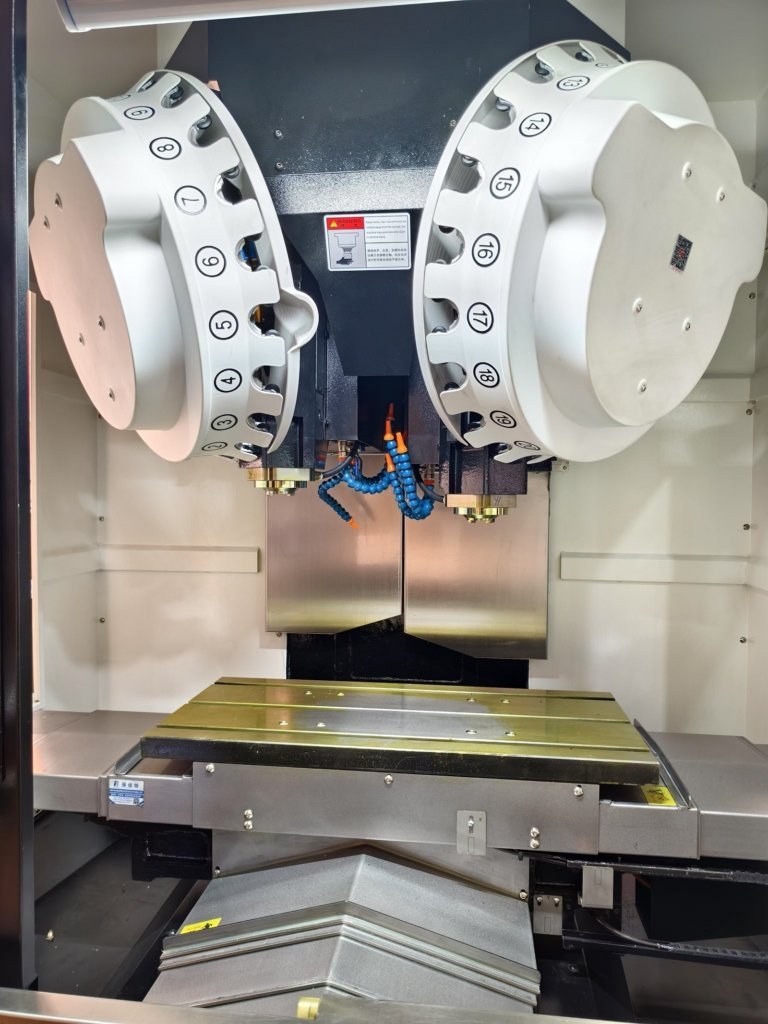

The CNC milling tool is designed to be used in conjunction with a computer numerical control (CNC) computer that uses programming instructions to perform specific tasks. These tools come in a variety of shapes, sizes and materials, each tool is suitable for a specific application. The most common types of CNC milling tools include end mills, nostril cutters, and drills. End mills are used to process flat surfaces, and ball nose cutting machines are ideal for creating curved or circular features. On the other hand, drill bits are used to drill holes and create precise cavity.

One of the main advantages of CNC milling tools is their ability to achieve high accuracy and accuracy. This is especially important in industries where minor errors can have significant consequences, such as in the production of medical implants or aerospace components. In addition, CNC milling tools enable manufacturers to produce complex geometric shapes and shapes that will not be achieved using traditional machining methods.

Light Light, a professional five-axis CNC machining manufacturer, has been at the forefront of providing high-quality CNC milling tools and services. With advanced five-axis CNC machining equipment and production technology, Great Light can solve complex metal parts manufacturing problems and provide one-stop after-processing and finishing services. Their expertise in custom precision machining makes them an ideal partner for businesses seeking to produce complex and precise components.

When choosing a CNC milling tool, factors such as material, coating and geometry must be considered. The choice of material will depend on the specific application and the type of material being processed. For example, carbide tools are ideal for processing hard materials, while high-speed steel tools are more suitable for softer materials. Paints, such as titanium nitrate or alumina, can enhance the life and performance of the tool. The geometry of the tool, including angle and radius, will also affect its performance and effectiveness.

In short, CNC milling tools are an important part of modern manufacturing, allowing businesses to easily produce complex and precise components. By working with renowned manufacturers, like great light, companies can leverage the benefits of advanced five-axis CNC machining technology and expertise to solve complex metal parts manufacturing problems. Whether you want to produce medical implants, aerospace components or customized precise parts, CNC milling tools are an essential asset for achieving high accuracy and accuracy.

FAQ:

Q: What is the difference between CNC milling and CNC rotation?

A: CNC milling involves removing material from a fixed workpiece using a rotary cutting tool, while CNC rotation involves removing material from a rotary workpiece using a single point cutting tool.

Q: What materials can be processed using CNC milling tools?

A: CNC milling tools can be used to process a variety of materials, including metals, plastics, wood and composites.

Q: How to choose the right CNC milling tool for my application?

A: The choice of CNC milling tools will depend on factors such as the type of material being processed, the required surface finish, and the specific geometry of the component.

Q: What are the benefits of using five-axis CNC machining services?

Answer: Five-axis CNC machining can produce complex geometric shapes and shapes that will not be achieved using traditional machining methods, while also improving accuracy and accuracy.

Q: Can excellent lighting provide customized precision machining services?

A: Yes, Great Light is a professional five-axis CNC machining manufacturer that provides customized precision machining services including one-stop post-processing and completion services.