When it comes to CNC processing, one of the most critical factors that manufacturers and businesses consider is cost. The cost of CNC machining may depend on several factors, and understanding these factors is essential to obtain the best value of your money. In this article, we will dig into the key cost factors that affect CNC machining and explore how to optimize production costs.

Material Cost

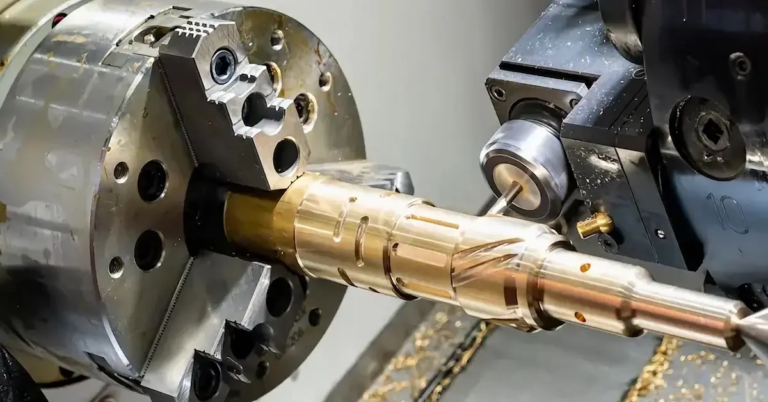

The type and quantity of materials used are important cost factors for CNC processing. The prices of different materials vary, and the costs range from a few dollars to a few hundred dollars per pound. For example, aluminum and copper are generally cheaper than titanium and stainless steel. The thickness and size of the material can also affect the cost, as larger and thicker materials require more material and processing time.

Design Complexity

The design complexity of this section is another crucial cost factor. Parts with complex designs, complex geometry or tight tolerances require more machining time, professional tools and skilled labor, increasing costs. On the other hand, simple designs with direct geometry are cheap to produce. To reduce costs, your design must be optimized and the design used for assembly (DFA) and manufacturing design (DFM) principles must be considered.

Processing time and labor

Processing time and labor costs are directly related to the complexity of the design and the materials used. More complex parts require longer machining time and more skilled labor, which increases costs. In addition, labor costs vary by location, and labor costs in some areas are higher than others.

Equipment and Tool Cost

The cost of equipment and tools is another important factor in CNC machining. High-performance machines and professional tools such as five-axis CNC machines can be expensive to buy and maintain. However, they can also increase productivity and reduce processing time, saving costs in the long run.

Post-processing and completion of services

Post-treatment and finishing services, such as surface finishing, heat treatment and inspection, can increase the overall cost of CNC processing. These services are critical to ensuring the quality and performance of the final product, but the costs may vary depending on the type and complexity of the process.

Quantity and production

The quantity and production of parts can seriously affect the cost of CNC machining. Higher output can lead to economies of scale, thereby reducing unit costs. However, small production volumes or disposable parts can be more expensive due to the required setup costs and processing time.

in conclusion

In summary, the cost of CNC machining is affected by a variety of factors, including material cost, design complexity, processing time and labor, equipment and tool costs, post-processing and completion services, and quantity and production volume. By understanding these factors and optimizing the production process, you can reduce costs and get the best value. When choosing a CNC machining service provider, consider factors such as their expertise, equipment and production capacity to ensure you get high-quality parts at a competitive price.

FAQ

Q: What is the most important cost factor in CNC processing?

A: The most important cost factor in CNC processing is material cost, because the prices of different materials vary, and the cost ranges from a few dollars to a few hundred dollars per pound.

Q: How to reduce the cost of CNC processing?

A: To reduce the cost of CNC processing, consider optimizing the design with cheaper materials and reducing the complexity of the design.

Q: What is the difference between CNC machining and 3D printing?

A: CNC machining and 3D printing are both manufacturing processes, but their methods vary. CNC machining involves removing material from solid blocks, while 3D printing involves adding material layer by layer.

Q: Can I get a quote for CNC processing services online?

A: Yes, many CNC machining service providers offer online citation tools that allow you to upload design files and receive quotes based on materials, quantity and other factors.

Q: What is the typical lead time for CNC processing services?

A: Typical lead time for CNC machining services depends on the complexity of parts, materials and production volume. However, most service providers can deliver parts within 1-4 weeks according to specific requirements.