Step-by-step guide to CNC processing

In today’s high-tech world, computer numerical control (CNC) processing has become an indispensable technology in manufacturing and production. CNC processing is an automated process that uses computer-controlled machines to manufacture parts and products in an accurate and accurate manner. But what exactly is CNC processing and how does it work? In this article, we will look at the basics of CNC processing and provide a step-by-step guide on how it works.

What is CNC processing?

CNC processing is a manufacturing technology that uses computer-controlled machines to cut, form and create precise parts and products. The process involves computer-aided design (CAD) design, which is then converted into G-code, which the language can understand. The G code is loaded into a CNC computer and then uses the code to perform the required operations such as cutting, drilling or milling.

CNC Processing: Step-by-step Guide

The CNC processing process involves multiple steps:

- Design and CAD: The first step is to use computer-aided design (CAD) software to create a digital design of a part or product.

- G code generation: Then convert the CAD design to G code, a language that the CNC machine can understand.

- NC code assembly: The G code is then assembled into a machine-readable format called NC code.

- Machine preparation: The CNC machine is ready for production, which includes setting up the machine, loading the G code and calibrating the machine.

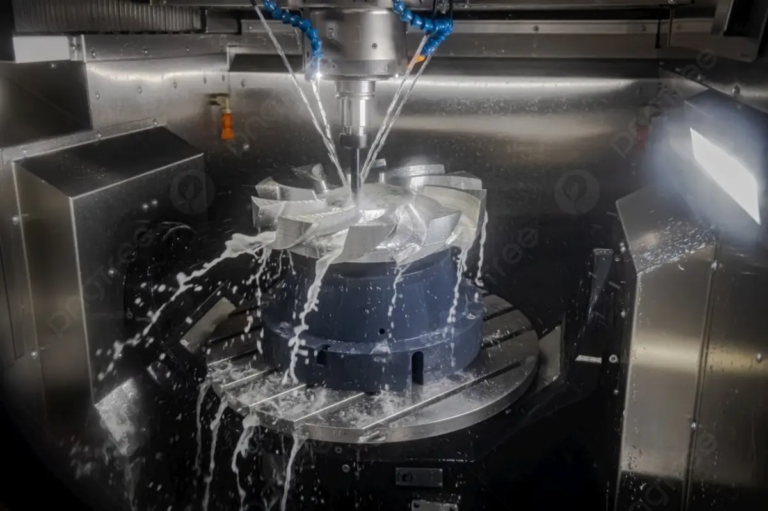

- Cutting and Shaping: The machine then uses G code to cut, shape and create parts or products.

- Post-processing: Then check the parts or products for any defects or defects.

Advantages of CNC processing

CNC processing offers several advantages, including:

- Improve accuracy: CNC processing allows for high accuracy and accuracy, which is essential for many industries such as aerospace, automotive and medical care.

- Improve efficiency: CNC processing is a fast and efficient process that reduces production time and improves productivity.

- Cost savings: CNC processing is a cost-effective way to produce parts and products because it eliminates the need for manual labor and human error.

in conclusion

In short, CNC processing is a highly accurate and efficient manufacturing technology that uses computer-controlled machines to create parts and products. By following the step-by-step guide outlined above, you can understand the fundamentals of CNC processing and how it works. Whether you are in manufacturing or just looking for a new way to create and produce parts, CNC processing is an exciting innovative technology that offers many advantages.

FAQs (FAQs)

- What is CNC processing? CNC processing is a manufacturing technology that uses computer-controlled machines to tailor, shape and create parts and products at precise and accurate speeds.

- What steps are involved in the CNC processing process? The steps involved in the CNC processing are design and CAD, G code generation, NC code compilation, machine preparation, cutting and shaping, and post-processing.

- What are the advantages of CNC processing? Advantages of CNC processing include improved accuracy, increased efficiency and cost savings.

- Which industries benefit from CNC processing? CNC processing benefits industries that require high accuracy and accuracy, such as aerospace, automotive and medical care.

- Can anyone use CNC processing? CNC processing is not limited to experts; with proper training and guidance, anyone can use CNC processing to create and produce parts and products.