With the continuous development of technology, the production of customized mobile phone cases has developed into a combination of cutting-edge innovations such as CNC processing. The professional five-axis CNC machining manufacturer Light Light meets the thriving demand for customized telephone cases by providing high-precision machining services, which is the forefront of this revolution. In this article, we will dig into the world of CNC machining and explore its role in creating unique durable phone cases.

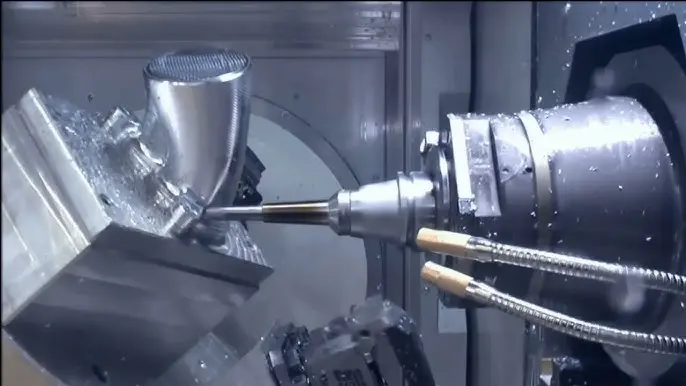

CNC machining or computer numerical controlled machining is a manufacturing process that uses computer-controlled machines to accurately cut and shape various materials. It allows the production of complex parts with complex details, making it an ideal solution for custom phone case manufacturing. Great Light’s five-axis CNC machining technology enables the production of complex shapes and designs with significant accuracy, ensuring that each situation meets the highest standards of quality and durability.

One of the main advantages of CNC machining is its ability to produce custom phone cases accurately and quickly. This manufacturing process eliminates the need for human error, reducing production time and improving accuracy. Additionally, CNC machining allows the use of a variety of materials, including metals, plastics and composites, allowing for the creation of a durable and lightweight phone case.

The rise of 3D printing has also had a significant impact on the production of customized telephone cases. However, while 3D printing can produce complex shapes, it lacks the accuracy and accuracy of CNC machining. CNC machining provides a level of detail and finish, while 3D printing is unparalleled, making it the first choice for high-end phone cases.

Another important benefit of CNC machining is its ability to create custom phone cases with unique features and designs. From complex patterns to custom colors and textures, CNC machining can produce truly unique phone cases. Traditional manufacturing methods cannot achieve this level of customization, which allows CNC to process game-changers in the production of customized mobile phone cases.

In addition to the benefits, CNC machining offers several advantages, including reducing waste, improving tool life and enhancing product durability. The accuracy and accuracy of CNC processing leads to less material loss in the production process, reducing waste and minimizing the environmental impact of manufacturing. In addition, the use of high-quality tools and advanced machining techniques can lead to extended tool life, lower production costs and increase efficiency.

in conclusion

In short, CNC machining revolutionizes the production of custom phone cases by providing unparalleled accuracy and customization with other manufacturing methods. Great Light’s five-axis CNC machining technology can produce complex shapes and designs with excellent accuracy, making it the ideal solution for producing high-quality and durable phone cases. Whether you are looking for a custom phone case with a unique design or a durable phone box that can withstand daily wear and tear, CNC machining is the perfect solution.

FAQ

Q: What is CNC machining and how does it work?

A: CNC machining is a manufacturing process that uses computer-controlled machines to accurately cut and shape various materials. It generates a cutting plan by using computer-aided design (CAD) software, which is then executed by a CNC computer.

Q: What are the benefits of CNC machining for custom phone cases?

A: CNC machining offers a variety of benefits including precision and speed, customizability, durability and reduced waste.

Q: Can CNC machining produce complex shapes and designs?

A: Yes, CNC machining is able to produce complex shapes and designs with excellent accuracy, making it an ideal solution for custom phone cases.

Q: What CNC-processed materials can be used?

A: CNC processing can be used in a variety of materials, including metals, plastics and composites.

Q: How does CNC machining compare with 3D printing?

A: Although 3D printing can produce complex shapes, it lacks the accuracy and accuracy of CNC machining. CNC machining provides a level of detail and finish, while 3D printing is unparalleled.

Q: What are the advantages of CNC processing compared to traditional manufacturing methods?

A: CNC machining provides several advantages, including reducing waste, improving tool life and enhancing product durability.