Precise Art: Perfect Processing of CNC Industrial CNC

In the modern manufacturing sector, accuracy and accuracy are key to producing high-quality products that meet the needs of the industry. Among many techniques that have reached this level of accuracy, Czech CNC (Computer Numerical Control) processing is a well-established method for many years. In this article, we will dig into the world of Czech CNC machining and explore its features, benefits and why it is the preferred choice for many manufacturers.

The evolution of CNC machining

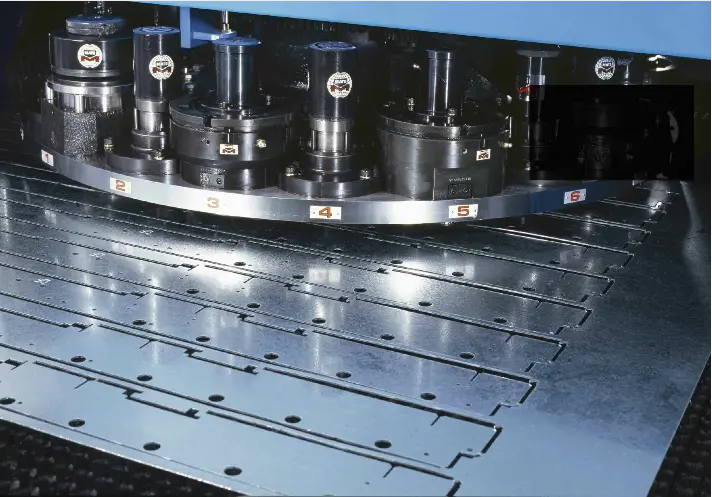

CNC machining involves the use of a computer-controlled machine to remove excess material from the workpiece, thereby shaping it into the desired form. The process relies on CAD (Computer Aided Design) software to create a digital blueprint of the part and then convert it into a set of instructions followed by the machine to generate the final product. The introduction of CNC machining revolutionized the manufacturing situation, thus enabling the creation of complex parts with complex characteristics and precise tolerances.

Benefits of CNC machining

Czech CNC machining has several benefits that make it an attractive choice for manufacturers. Some key advantages include:

- High precision: Czech CNC machining allows for ultra-high precision, ensuring that parts are manufactured in accordance with the strict specifications required by modern industry standards.

- speed: CNC machines can handle complex parts quickly and efficiently, reducing production time and improving productivity.

- consistency: The accuracy of CNC machining ensures that each part is the same as the next part, eliminating variability and inconsistency.

- Material versatility: Czech CNC machining can be used with a variety of materials including metals, plastics and composites.

- custom made: CNC machines can be programmed to produce custom parts with complex geometry and functions.

Application of CNC machining in Czech

The accuracy and versatility of CNC machining make it suitable for a variety of applications in various industries, including:

- aerospace: Czech CNC machining is used to produce critical aircraft components such as engine parts, turbine blades and satellite components.

- car: CNC machining is used in the production of automotive parts, including engine components, transmission and chassis parts.

- Medical: Accurate CNC machining is used to create medical implants, surgical instruments and medical devices.

- Industrial: Czech CNC machining is used to produce industrial equipment such as mechanical components, hardware and tools.

Expectations of a reputable CNC machining service provider

When working with Czech CNC machining service providers, you can expect:

- Professional knowledge: An experienced team of engineers and mechanics with a deep understanding of CNC machining technology.

- Quality control: Strict quality control measures to ensure that parts meet the required specifications.

- Quick turnaround time: Rapid production time, usually within a few hours or days, not weeks or months.

- Material Availability: A wide range of materials that can be used for processing.

- Competing Price: Competitive pricing without compromising quality.

in conclusion

Czech CNC machining revolutionized the manufacturing industry with unparalleled accuracy, speed and versatility. By working with reputable CNC machining service providers, manufacturers can ensure that their products meet the highest standards of quality and performance. Whether used in aerospace, automotive, medical or industrial applications, Czech CNC machining is an ideal solution for producing complex parts with precision and efficiency.

FAQ

Q: What is CNC processing?

A: CNC machining involves the use of a computer-controlled machine to remove excess material from the workpiece, thereby shaping it into the desired form.

Q: What are the benefits of CNC processing in Czech Republic?

A: The benefits of Czech CNC machining include high precision, speed, consistency, material versatility and customization.

Q: Which industries use Czech CNC processing?

A: Various industries, including aerospace, automotive, medical and industrial, use Czech CNC processing.

Q: How long does it take to process CNC?

A: CNC machining can produce parts in hours or days, depending on the complexity of the parts used and the machine.

Q: Can CNC machining be used to work with different materials?

A: Yes, CNC processing can use a variety of materials, including metals, plastics and composites.