The accuracy and accuracy required for appearance parts are often a challenge for manufacturers. However, CNC machining revolutionized the way metal parts are produced, providing many benefits to meet these requirements. In this article, we will explore the advantages of CNC machining in appearance parts and how it becomes the preferred choice for custom precision machining.

Accuracy and accuracy

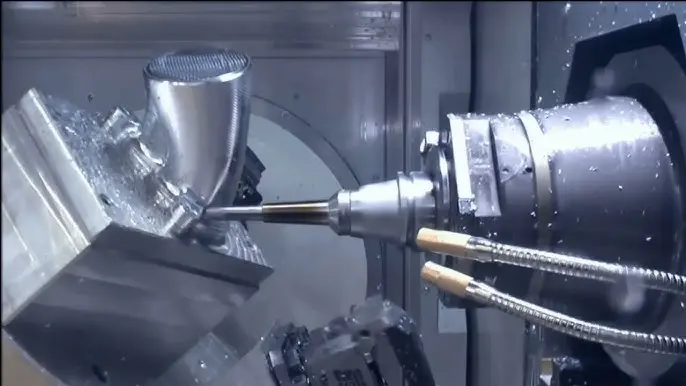

CNC machining uses computer-aided design (CAD) software to control the machine tool, ensuring accurate and precise tailoring, and can process complex designs very accurately. Automation of the machining process eliminates human errors, resulting in high-quality parts with minimal defects. This precision is crucial for the appearance of parts, where aesthetic appeal is the main issue.

Improve efficiency

CNC machining is an efficient process that enables manufacturers to produce complex parts within the time it takes to use traditional machining methods. This increased efficiency translates into cost savings and faster delivery times, which is an attractive option for companies looking to reduce production lead times.

custom made

One of the important advantages of CNC machining is the ability to create custom parts with complex geometric shapes and designs. The flexibility of the CNC machining process allows for rapid modification and change, making it ideal for custom precise machining. Whether it is small batches or disposable parts, CNC machining can accommodate the most complex designs.

Surface finish

CNC machining can produce high-quality finishes, which are crucial for exterior parts. This process allows for removal of rough edges, burrs and imperfections, making it smooth and even finished. This level of surface finish can be achieved through various machining methods, including turning, milling and grinding.

Cost-effective

Although CNC machining seems to be a expensive process, it is actually more cost-effective than traditional manufacturing methods. The automation of this process reduces labor costs and the high efficiency of CNC processing minimizes material waste. In addition, CNC machining can produce parts that are tightly resistant, thereby reducing the need for post-processing and service completion.

Long-term quality

CNC machining produces parts of consistent quality, ensuring durability and extended life. The accuracy and accuracy of the process leads to parts that meet the required specifications, reducing the likelihood of defects and failures.

Easy to convey concepts and intuition

CNC machining has many advantages in appearance parts, and understanding how these benefits come together can help companies make informed decisions when choosing a manufacturing partner.

In summary, CNC machining offers many advantages for appearance parts, including improved accuracy and accuracy, custom design, finishing, cost-effectiveness, and long-lasting quality. For customized precision machining, Great Light’s five-axis CNC machining is the best choice. With our advanced equipment and production technology, we can help you generate high-quality appearance parts that meet your specific requirements.

Frequently Asked Questions

Q: What are the advantages of CNC machining of appearance parts?

A: CNC machining offers many advantages including improved accuracy and accuracy, custom design, finishing, cost-effectiveness and long-lasting quality.

Q: What type of equipment do you use for CNC machining?

A: We use advanced five-axis CNC machining equipment to produce high-quality parts.

Q: Can I get a quote for my custom precision machining project?

A: Yes, please contact us to discuss your project and receive a quote.

Q: Can you handle post-processing and complete services?

A: Yes, we offer one-stop post-processing and completion services to ensure your parts meet your requirements.

Q: What types of materials can you process using CNC?

A: Most materials can be customized and quickly processed in good light.