CNC Gantry Machining Center Technology: Guide to its Functions and Applications

CNC (Computer Numerical Control) processing technology revolutionized the manufacturing industry by providing precise and effective production capacity. Among various types of CNC machines, gantry machining centers have become increasingly popular due to their versatility and ability to perform complex operations. In this blog post, we will dig into the world of CNC Gantry Machining Center to explore its features, applications and benefits.

What is CNC Gantry Machining Center?

The CNC Gantry Machining Center is a CNC machine that uses a movable gantry man to move the spindle or tool head to perform machining operations. The gantry is usually supported by two or three vertical columns, allowing unrestricted movement in the X, Y and Z axes. This design enables the machine to access parts from multiple angles, making them ideal for complex machining operations.

Functions of CNC Gantry Machining Center

The CNC Gantry Machining Center is capable of performing a wide range of machining operations, including:

1. Milling: CNC gantry machining centers can be used for milling operations such as cutting, drilling and facing.

2. Rotating: The machine can also be used for rotating operations, including lathe style operation and cylindrical grinding.

3. Grinding: The CNC gantry machining center can be equipped with grinding wheels for precise grinding and finishing operations.

4. EDM: Electrical machining (EDM) can be performed on the CNC gantry machining center, allowing for the creation of complex metal parts with smaller features.

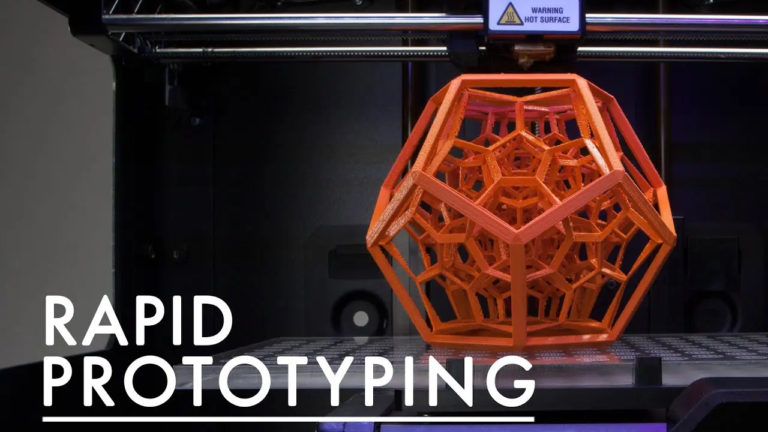

5. 3D Printing: Some CNC gantry machining centers can be equipped with 3D printing capabilities, allowing for rapid prototyping and production of complex parts.

Application of CNC Gantry Machining Center

CNC gantry machining centers are widely used in various industries, including:

1. Aerospace: The ability of machines to perform complex operations makes it ideal for producing aerospace components.

2. Automotive: CNC gantry machining center is used for the production of automotive parts such as engine components and transmission systems.

3. Medical: The precise function of the machine makes it suitable for the production of medical equipment including surgical instruments and implants.

4. Energy: CNC gantry machining centers are used to produce energy-related components such as power generation equipment and wind turbine blades.

Benefits of CNC Gantry Machining Center

The benefits of using a CNC gantry machining center include:

1. Improved Accuracy: The machine’s ability to perform complex operations with high precision makes it ideal for applications with the highest accuracy.

2. Improved Efficiency: CNC gantry machining centers can perform multiple operations simultaneously, reducing production time and increasing efficiency.

3. Multifunctionality: The machine’s ability to perform various operations makes it a multifunctional solution for various industries.

4. Cost-effective: CNC gantry machining centers are more cost-effective than traditional machining methods, especially for complex operations.

in conclusion

The CNC Gantry Machining Center is a powerful tool that provides high accuracy, versatility and efficiency. By understanding the functions and applications of these machines, manufacturers can make informed decisions about their production processes and achieve better results. Whether you are producing parts for aerospace, automotive, medical or energy applications, CNC Gantry Machining Center is an excellent choice.

FAQ:

1. What is CNC Gantry Machining Center?

The CNC Gantry Machining Center is a CNC machine that uses a movable gantry man to move the spindle or tool head to perform machining operations.

2. What is the function of CNC gantry machining center?

The CNC gantry machining center can perform milling, rotation, grinding, EDM and 3D printing operations.

3. What is the application of CNC gantry machining center?

The CNC Gantry Machining Center is used in the aerospace, automotive, medical and energy industries, as well as other sectors that require complex operations.

4. What are the benefits of using a CNC gantry machining center?

The benefits of using a CNC gantry machining center include increased accuracy, increased efficiency, versatility and cost-effectiveness.

5. Can CNC gantry machining center perform complex operations?

Yes, the CNC Gantry Machining Center is designed to perform complex operations including 3D printing, EDM and precision grinding.

6. Can CNC gantry machining center be used for small-scale production?

CNC gantry machining centers can be used for small-scale production as well as large-scale production. However, the functionality and application of the machine will depend on the specific requirements of the project.

7. What are the maintenance requirements for CNC gantry machining center?

The CNC gantry machining center requires regular maintenance to ensure optimal performance. This includes cleaning the machine, checking for wear and routine inspection of machine components.