CNC machining fundamentals explain

CNC machining, representing computer numerical controlled machining, is a manufacturing process used to create complex shapes and designs in a variety of materials, including metals and plastics. CNC machining has become an important process in many industries, including aerospace, automotive and medical equipment. But for those who are CNC processing, understanding the basis of this process can be overwhelming. In this article, we will provide a comprehensive overview of the basics of CNC machining covering the basics of CNC machining, machine types and the benefits of CNC machining.

Basic knowledge of CNC processing

CNC machining uses a computer-controlled machine to remove material from the workpiece to create the desired shape. The process begins with the creation of a computer-aided design (CAD) model for the parts to be manufactured. The CAD model is then converted into numerical codes that the CNC computer can understand. Numerical codes are used to control the movement of a machine cutting tool, which is usually a rotary cutting tool or laser.

Machine Type

There are several types of CNC machines, each with its unique features and applications. Some common types of CNC machines include:

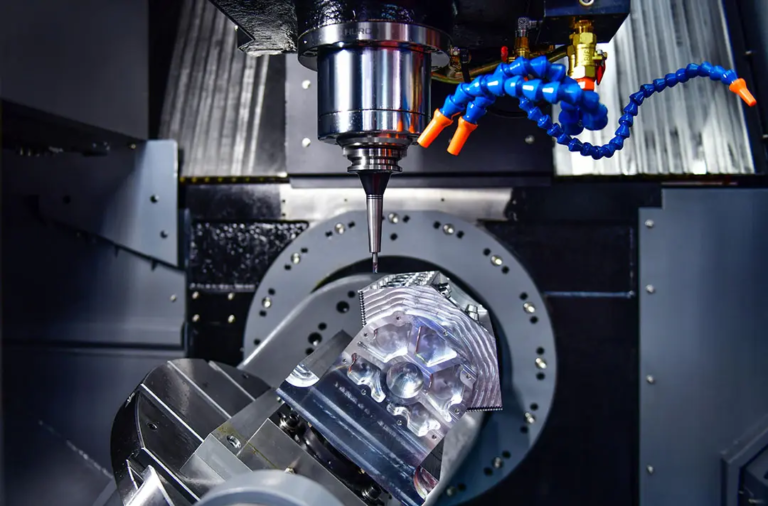

*Milling machines: These machines use rotary cutting tools to remove material from workpieces. Milling machines are often used to create flat surfaces, grooves and holes.

*Bent Machines: These machines use rotary cutting tools to remove material from the workpiece from the outside. Bending machines are often used to create cylindrical surfaces such as tubes and shafts.

* Grinders: These machines use abrasive cutting tools to remove material from the workpiece. Grinders are often used to create precise surfaces such as bearings and other mechanical components.

* Five-axis machines: These machines can move in five different directions, allowing for the creation of complex shapes and designs. Five-axis machines are often used to create complex shapes and designs in aerospace and medical devices.

Benefits of CNC machining

CNC machining offers a variety of benefits, including:

*High Accuracy: CNC machines can achieve accurate tolerances of ±0.01 mm or higher, which is ideal for applications where accuracy is critical.

*High speed: CNC machines can produce parts at high speed, reducing overall production time and cost.

* Flexibility: CNC machines can be programmed to produce a variety of parts and designs, making them ideal for small volume and high mix production.

*Automation: CNC machines can be automated, thereby reducing the need for manual labor and improving efficiency.

in conclusion

In short, CNC machining is a highly accurate and efficient manufacturing process used to create complex shapes and designs in a variety of materials. By understanding the basics of CNC machining, machine type and the benefits of CNC machining, readers can better understand this process and its application in various industries.

FAQ

Q: What is CNC processing?

A: CNC machining is a manufacturing process that uses a computer-controlled machine to remove material from the workpiece to create the desired shape.

Q: How does CNC machining work?

A: CNC machining uses computer-aided design (CAD) models to create numerical codes to control the movement of machine cutting tools, which are usually rotating cutting tools or lasers.

Q: What type of CNC machine are there?

A: There are several types of CNC machines, including milling machines, turning machines, grinders and five-axis computers.

Q: What are the benefits of CNC processing?

A: The benefits of CNC machining include high precision, high speed, flexibility and automation.

Q: Can CNC processing be used for any material?

A: CNC processing can be used in a variety of materials, including metals, plastics and composites. However, some materials may require special consideration or programming.

Q: What is the cost of CNC processing?

A: The cost of CNC machining may vary depending on the complexity of the parts, the materials used and the production volume. Generally, CNC machining may be more expensive than other manufacturing processes, but it has high accuracy and flexibility.