Understanding CNC Machining: 3 Common Remuneration Methods for Improved Accuracy

As the importance of precision and efficiency in CNC machining continues to grow, it’s crucial for professionals to stay abreast of the latest techniques and innovations. In this post, we’ll delve into the world of remuneration methods, exploring the tools and strategies that can help machining centers optimize their operations and deliver exceptional results.

Compensation Methods: A Brief Overview

Before we dive into the specifics, it’s essential to understand that remuneration methods are designed to help machining centers overcome common challenges, such as tool length and radius variations, and ensure accurate processing. By using the right compensation techniques, CNC machining centers can achieve greater precision, reduce production time, and improve overall efficiency.

Method 1: Tool Length Compensation

In this method, the CNC machining center calculates the required length compensation for each tool based on its unique characteristics. This is particularly important when processing multiple parts with varying tool lengths. By compensating for tool length, machining centers can ensure accurate processing and prevent tool damage.

Case Study:

A machining center is processing a complex part with multiple components, each requiring a different tool length. By using tool length compensation, the machining center can accurately calculate the required tool length for each component, reducing the risk of tool damage and ensuring precise processing.

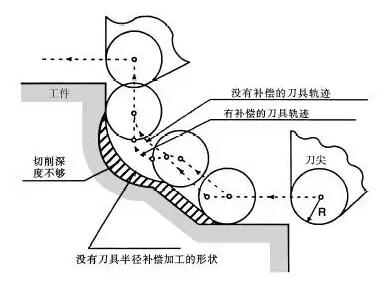

Method 2: Tool Radius Compensation

In this method, the CNC machining center calculates the required radius compensation for each tool based on its unique characteristics. This is particularly important when processing parts with complex shapes or curvatures. By compensating for tool radius, machining centers can ensure accurate processing and prevent tool damage.

Case Study:

A machining center is processing a part with a complex curvature, requiring a specific tool radius. By using tool radius compensation, the machining center can accurately calculate the required tool radius, ensuring precise processing and preventing tool damage.

Method 3: Lighting Off-Set Compensation

In this method, the CNC machining center calculates the required off-set compensation for each tool based on its unique characteristics. This is particularly important when processing small parts or components. By compensating for lighting off-set, machining centers can ensure accurate processing and prevent tool damage.

Case Study:

A machining center is processing a small part with complex geometry, requiring precise processing. By using lighting off-set compensation, the machining center can accurately calculate the required off-set, ensuring precise processing and preventing tool damage.

7 Things to Note When Implementing Remuneration for the Tool Department

- Establishment and Cancellation of the Compensation Mode: The process of establishing and canceling the compensation mode can only be valid in mobile control mode G00 or G01.

- G41/G42 Instructions: These instructions have no parameters, and their compensation number (represents the compensation value of the cutting edge that corresponds to the tool used) is specified by the T command.

- Tangent Cut or Normal Cut: Use a tangent cut or normal cut to establish or cancel the remedy of the knife.

- Tool Shift Direction: Pay particular attention to the difference between the front tool holder and the rear tool holder when selecting the shift direction and the position of the edge of the tip of the tool.

- Program Block: In the tool for compensation, instructions not moved to the compensation plan which are more than two consecutive sections are generally not authorized, otherwise the tool will also experience dangerous actions such as overcutting.

- Program Pause: In the tool for compensation, program pause blocks (G04 X10.0) with only the instructions G, M, S, F, and T are generally not authorized.

By implementing these remuneration methods, CNC machining centers can improve accuracy, reduce production time, and enhance overall efficiency. As the demand for precision and efficiency continues to grow, it’s crucial for professionals to stay abreast of the latest techniques and innovations in CNC machining.

Conclusion:

In this post, we’ve delved into the world of remuneration methods, exploring the tools and strategies that can help machining centers optimize their operations and deliver exceptional results. By understanding and implementing these compensation methods, CNC machining centers can improve accuracy, reduce production time, and enhance overall efficiency.