High-precision Aluminum CNC machining: Unlocking the full potential of metal parts manufacturing

In today’s fast-paced manufacturing environment, accuracy is key. Metal parts in particular require excellent accuracy to ensure optimal performance, reliability and life. As a result, high-precision aluminum CNC machining has become an important process in the production of complex parts and components. In this article, we will delve into the world of high-precision aluminum CNC machining and explore its advantages, functions and applications.

What is high-precision aluminum CNC machining?

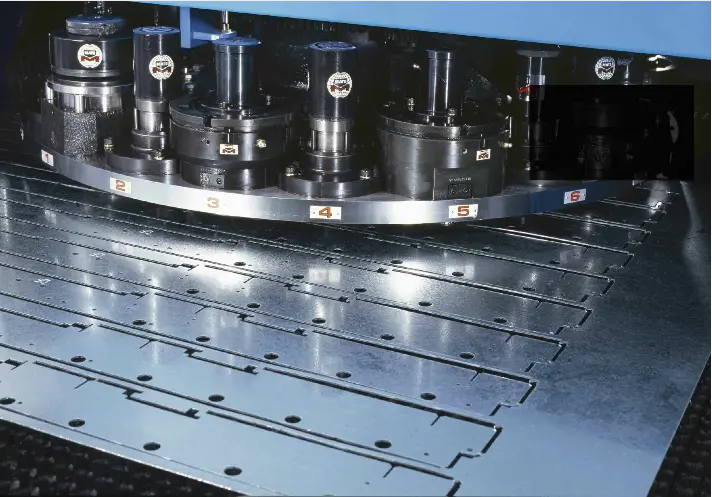

High-precision aluminum CNC machining is a complex manufacturing process that combines computer numerical control (CNC) machining with advanced aluminum materials. This process enables the production of complex metal parts with high accuracy, accuracy and surface finish. By leveraging the benefits of CNC machining, manufacturers can create parts with complex features, complex geometry and high surface finishes while ensuring optimal performance and reliability.

Benefits of high-precision aluminum CNC machining

So, what makes high-precision aluminum CNC machining so valuable? Here are some key benefits:

- High precision: High-precision CNC machining allows parts to be produced with extremely high accuracy, minimizing defect risk and ensuring optimal performance.

- Complex parts production: With the help of CNC machining, manufacturers can produce complex parts with complex features, complex geometry and high surface finishes.

- Improve efficiency: High-precision CNC machining simplifies the manufacturing process, reduces lead time and improves productivity.

- Top surface finish: This process achieves excellent finishes, reducing the need for additional completion operations and ensuring optimal performance.

Functions of high-precision aluminum CNC machining

High-precision aluminum CNC machining provides a range of features including:

- Three-axis machining: High-precision CNC machining can be performed using three-axis or five-axis computers, so that complex parts with complex functions can be produced.

- Customized parts production: Using high-precision CNC machining, manufacturers can produce custom parts to meet specific requirements, ensuring optimal performance and reliability.

- Material selection: High-precision aluminum CNC processing provides a range of aluminum materials, each with unique characteristics and benefits.

Application of high-precision aluminum CNC machining

High-precision aluminum CNC processing has a wide range of applications in various industries, including:

- aerospace: This process is ideal for producing critical components such as aircraft parts, while high precision and reliability are crucial.

- car: High-precision aluminum CNC machining is used to produce high-performance parts such as engine components, transmission parts and suspension components.

- Medical: This process is used to produce medical equipment such as implantable parts, surgical instruments and diagnostic equipment.

in conclusion

High-precision aluminum CNC machining is a game changer in the manufacturing world, offering a range of benefits, features and applications. By leveraging this process, manufacturers can produce complex metal parts with high accuracy, accuracy and surface treatment, ensuring optimal performance and reliability. Whether you want to produce high-performance parts or complex components, high-precision aluminum CNC machining is ideal.

FAQ

Q: What is the typical accuracy of high-precision aluminum CNC processing?

Answer: The typical accuracy of high-precision aluminum CNC processing is +/- 0.01 mm.

Q: What types of materials can be used in high-precision aluminum CNC processing?

A: A range of aluminum materials (including 6061, 6063 and 7075) can be used for high-precision aluminum CNC processing.

Q: Can high-precision aluminum CNC processing be used for customized parts production?

A: Yes, high-precision aluminum CNC machining can be used to produce customized parts to meet specific requirements.

Q: Is high-precision aluminum CNC processing more expensive than traditional processing methods?

A: High-precision aluminum CNC machining is usually expensive than traditional processing methods, but it provides excellent accuracy, accuracy and surface effect.