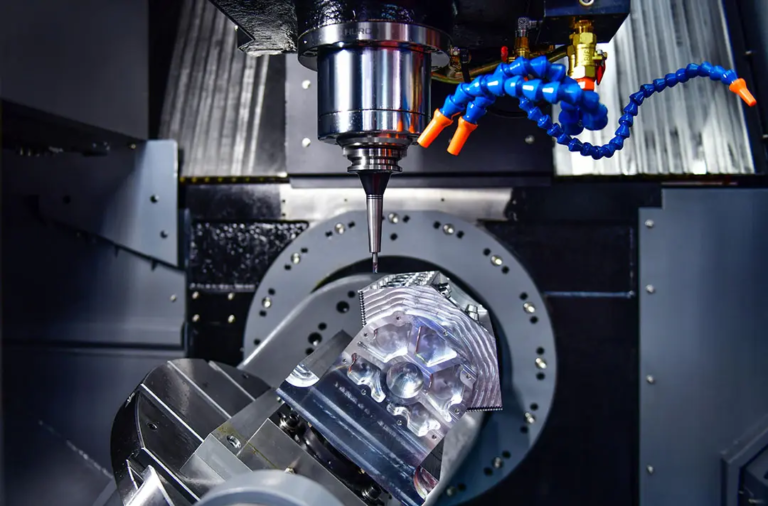

CNC Processing Materials 101: A Beginner’s Guide

As a beginner in the world of CNC machining, one must understand the various materials used in the process. CNC machining involves the use of computer-controlled machines to remove material from workpieces, and the type of material used can significantly affect the quality, durability, and cost of the final product. In this article, we will explore the most common CNC processing materials, their properties and their applications.

1. Aluminum (6061-T6)

Aluminum is a popular choice for CNC processing due to its excellent processability, high strength to weight ratio and corrosion resistance. It is commonly used in aerospace, automotive and consumer products.

2. Stainless steel (304/316)

Stainless steel is a durable corrosion-resistant material commonly used in medical equipment, aerospace and high-pressure applications. Its high strength and wear resistance make it an excellent choice for demanding industries.

3. Brass (360/C260)

Brass is a copper-zinc alloy that is easy to process and has good corrosion resistance. It is commonly used in musical instruments, hardware and electrical components.

4. Titanium (Titanium Level 5)

Titanium is a powerful, lightweight and corrosion-resistant metal that is often used in aerospace, medical equipment and high reliability applications. Its high strength weight ratio makes it ideal for weight-critical components.

5. Steel (1020/1045)

Steel is a common material for CNC machining due to its high strength, durability and affordability. It is widely used in construction, machinery and manufacturing industries.

6. Copper (belt)

Copper is an excellent electrical conductor and is commonly used in electronic components, wiring and radiators. Its high ductility and corrosion resistance make it suitable for demanding applications.

7. Delrin (acetyl)

Delrin is a popular synthetic material known for its high impact, low friction and excellent processing properties. It is commonly used in gears, bearings and other mechanical components.

8. Polyurethane (PU)

Polyurethane is a multifunctional material for a variety of applications, including medical devices, automotive parts and consumer products. Its excellent durability and flexibility make it ideal for demanding industries.

9. Nylon (Nylon 6/6)

Nylon is a popular synthetic material known for its high strength, rigidity and wear resistance. It is commonly used in bearings, gears and other mechanical components.

10. Carbon fiber (CF)

Carbon fiber is a lightweight, high-strength material often used in aerospace, automotive and sports equipment. Its excellent strength to weight ratio makes it ideal for critical weight applications.

in conclusion

In this article, we explore the most common CNC processing materials, their properties and their applications. Understanding the differences between materials can help you make informed decisions when choosing the right material for your project. Whether you are a beginner or an experienced professional, this guide should provide valuable insights to help your CNC machining efforts.

FAQ

Q: What is the difference between steel and stainless steel?

A: Steel is a more general term, while stainless steel is a corrosion-resistant specific steel alloy.

Q: What is the best material for aviation applications?

A: Titanium is usually the preferred material for aerospace applications due to its high strength, low weight and corrosion resistance.

Q: Can I motorcycle aluminum at home?

A: Aluminum can be fixed at home, but it is recommended to use professional-grade CNC machines or consult an expert to ensure high-quality completion.

Q: What is the most durable material for heavy-duty applications?

A: Steel fibers are usually the best choice for heavy duty applications due to their high strength, rigidity and wear resistance.

Q: Can I tolerate stainless steel?

A: Yes, stainless steel can oxidize, but it requires special equipment and expertise.

Q: What is the most affordable material for prototype development?

A: Aluminum and Delin are usually the most affordable choices for prototype development because of their easy processing and relatively low cost.