Solving Common Problems in CNC Turning: A Guide to Precision and Efficiency

As a CNC turner, you’re no stranger to the challenges that come with precision turning. From damaged cutting wires to inaccurate threading, these issues can be frustrating and time-consuming to resolve. In this article, we’ll explore common problems you may face and present innovative solutions to ensure high-quality output and increased efficiency.

Understanding the Principle of Turning

Before we dive into the solutions, it’s essential to comprehend the principle of turning. A CNC turner machine uses a spindle encoder to generate a cutting signal, which is synchronized with the spindle rotation. This signal is used to control the servo motor, ensuring the exact rotation speed. However, there’s no direct mechanical connection between the spindle’s rotation and the supply movement, making it challenging to maintain accuracy when re-installing or re-threading parts.

Prevention and Control Measures

To minimize these issues, many CNC turners use a machine clip tool with a roughing and finishing operation. If the tool breaks, it’s often replaced without removing it, which can lead to poor thread quality and disorderly teeth. However, this approach may not be effective for complex threading applications or when working with small parts.

Solutions to Common Problems

Solution 1: Tool Damage and Re-Alignment

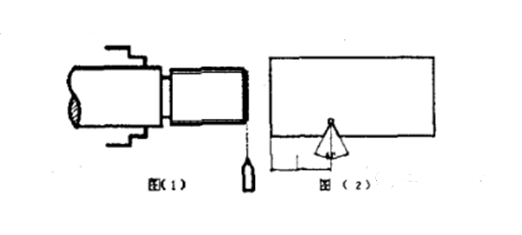

When a tool is damaged or needs to be replaced, re-alignment is crucial to ensure precision. A simple approach is to set the Z-axis to match the original position of the tool. This method is effective but may not always result in accurate alignment. A better approach is to use a precision angle model or a locally-made sample to measure the distance from the point of L (as shown in Figure 2). This method allows for precise compensation and is suitable for high-precision cutting tools.

Solution 2: Single Thread or Small Lots

When working with single thread or small lots, it’s common to encounter issues with inadequate thread depth. To resolve this, make an opening cover to eliminate the jump error. Once the parts are re-settled, use the method shown in Figure 4 to solve the cutting issue. This involves slowly running the wire at a low speed without treatment procedures, starting from the original point and moving the tool 2 mm at a time. Repeat this process until the tool touches the spiral groove, then re-run the program.

Solution 3: Large Lots of Threaded Parts

For large lots of threaded parts, a quick, simple, and precise method is necessary. I’ve developed a practical solution that involves modifying the original program to adjust the wire length. Start by running the program with a short and shallow thread, then modify the starting point (Figure 5). Pivot the piece from point 1 to point 2 to the AB marking line. If the part moves axially, the threaded tool must be reduced in the Z-axis. Once the part is settled, refine the starting point for the wire cut based on the error.

Conclusion

In this article, we’ve explored common problems in CNC turning and presented innovative solutions to ensure high-quality output and increased efficiency. By understanding the principle of turning, taking prevention and control measures, and applying these solutions, you can overcome the challenges of tool damage, re-alignment, and inadequate thread depth. Whether working with single thread or large lots of threaded parts, these methods will help you achieve precise results and overcome the frustrations of CNC turning.