The Full Screen CNC Method: Revolutionizing Manufacturing Processes with Enhanced Precision and Productivity

In the world of computer-aided manufacturing, the choice of machining method can make all the difference in terms of precision, productivity, and overall efficiency. Among the various methods, the full screen CNC method has emerged as a leader in terms of its ability to deliver unparalleled accuracy and speed. In this blog post, we will delve into the advantages of the full screen CNC method, exploring its benefits, limitations, and applications to help manufacturers optimize their manufacturing processes.

What is Full Screen CNC?

Full screen CNC, also known as full-screen machining or 5-axis machining, refers to a type of computer-numerical control (CNC) programming that enables a machine to move along five axes, including three linear axes (X, Y, and Z) and two rotational axes (A and C). This allows for the creation of complex shapes and designs with incredible precision, making it an ideal method for a wide range of industries, from aerospace to automotive.

Advantages of Full Screen CNC

- Enhanced Precision: Full screen CNC offers unparalleled precision, as the machine can move along multiple axes, precision-machining even the most intricate designs with ease. This translates to increased accuracy and reduced errors, resulting in higher-quality products.

- Increased Productivity: With the ability to machine complex shapes and designs, full screen CNC enables manufacturers to reduce production time and increase output. This is achieved by minimizing the need for rework and optimizing machining procedures.

- implified Change Management: The full screen CNC method allows for easier tool changes, as the machine can reposition itself quickly and precisely to accommodate different tools and operations.

- Improved Tool Life: The ability to machine complex designs with precision reduces the risk of tool breakage, resulting in extended tool life and reduced maintenance costs.

- Wider Design Capabilities: Full screen CNC enables manufacturers to produce complex shapes and designs that would be difficult or impossible to achieve with traditional machining methods.

- Enhanced Surface Finish: The precision and control offered by full screen CNC result in improved surface finish, reducing the need for additional finishing operations.

- Reduced Labor Costs: With the ability to automate many machining operations, manufacturers can reduce labor costs and allocate resources more efficiently.

- Increased Flexibility: Full screen CNC machines are capable of handling a wide range of materials, from soft woods to hard metals, accommodating various production demands.

Limitations and Challenges

While the full screen CNC method offers numerous advantages, it also presents some limitations and challenges:

- High Initial Investment: Full screen CNC machines require a significant upfront investment, making them less accessible to small- and medium-sized manufacturers.

- Complex Programming: Programming full screen CNC machines requires advanced knowledge and expertise, which can be a challenge for novice programmers.

- Machine Maintenance: Full screen CNC machines require regular maintenance to ensure optimal performance, which can be time-consuming and costly.

- Operator Training: Operators must receive extensive training to use the machine effectively, which can be a challenge for some manufacturers.

Conclusion

In conclusion, the full screen CNC method has revolutionized the manufacturing landscape, offering unparalleled precision, productivity, and flexibility. While it presents some limitations and challenges, the advantages far outweigh the disadvantages, making it an attractive option for manufacturers seeking to optimize their processes and improve product quality. By understanding the benefits and limitations of full screen CNC, manufacturers can make informed decisions about whether this technology is right for their production needs.

Layout:

[Header]

- Title: The Full Screen CNC Method: Revolutionizing Manufacturing Processes

- Subtitle: Enhancing Precision, Productivity, and Flexibility with 5-Axis Machining

[Intro]

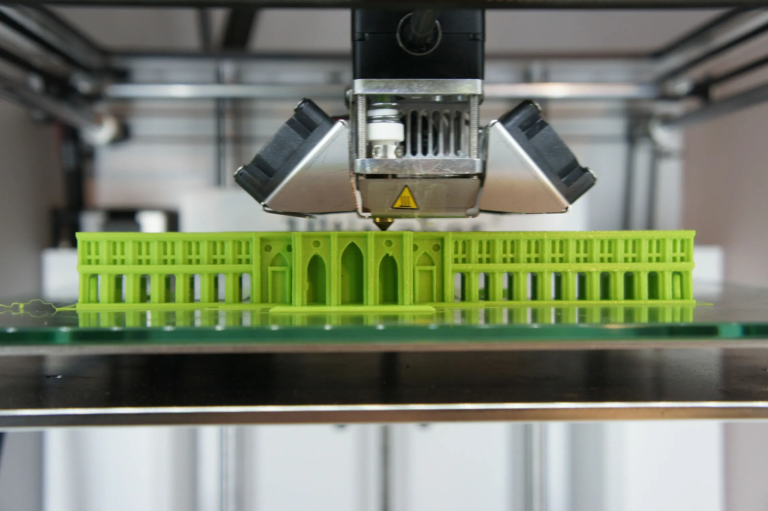

- Image: A 5-axis CNC machine in operation

- Text: In the world of computer-aided manufacturing, the choice of machining method can make all the difference in terms of precision, productivity, and overall efficiency. Among the various methods, the full screen CNC method has emerged as a leader in terms of its ability to deliver unparalleled accuracy and speed.

[Section 1: What is Full Screen CNC?]

- Blockquote: "Full screen CNC, also known as full-screen machining or 5-axis machining, refers to a type of computer-numerical control (CNC) programming that enables a machine to move along five axes, including three linear axes (X, Y, and Z) and two rotational axes (A and C)."

- Bullet points:

- Three linear axes (X, Y, and Z)

- Two rotational axes (A and C)

- Enables the creation of complex shapes and designs

[Section 2: Advantages of Full Screen CNC]

- Title: Advantages of Full Screen CNC

- Bullet points:

- Enhanced Precision

- Increased Productivity

- Simplified Change Management

- Improved Tool Life

- Wider Design Capabilities

- Enhanced Surface Finish

- Reduced Labor Costs

[Section 3: Limitations and Challenges]

- Title: Limitations and Challenges

- Bullet points:

- High Initial Investment

- Complex Programming

- Machine Maintenance

- Operator Training

[Conclusion]

- Title: Conclusion

- Text: In conclusion, the full screen CNC method has revolutionized the manufacturing landscape, offering unparalleled precision, productivity, and flexibility. By understanding the benefits and limitations of full screen CNC, manufacturers can make informed decisions about whether this technology is right for their production needs.

[Outro]

- Text: The full screen CNC method is a game-changer for manufacturers seeking to optimize their processes and improve product quality. With its numerous advantages, low risk of tool breakage, and reduced rework, it’s an attractive option for companies looking to improve efficiency and reduce costs.