The Revolutionary Power of CNC Machining: Unlocking Efficiency, Precision, and Innovation in Modern Manufacturing

In the world of manufacturing, innovation and efficiency are the keys to success. With the constant push for advancements, the field of manufacturing has evolved significantly over the years. One of the most significant developments is the rise of Computer Numerical Control (CNC) machine tools. In this post, we will delve into the world of CNC machining, exploring its advantages, benefits, and the positive impact it has had on modern manufacturing.

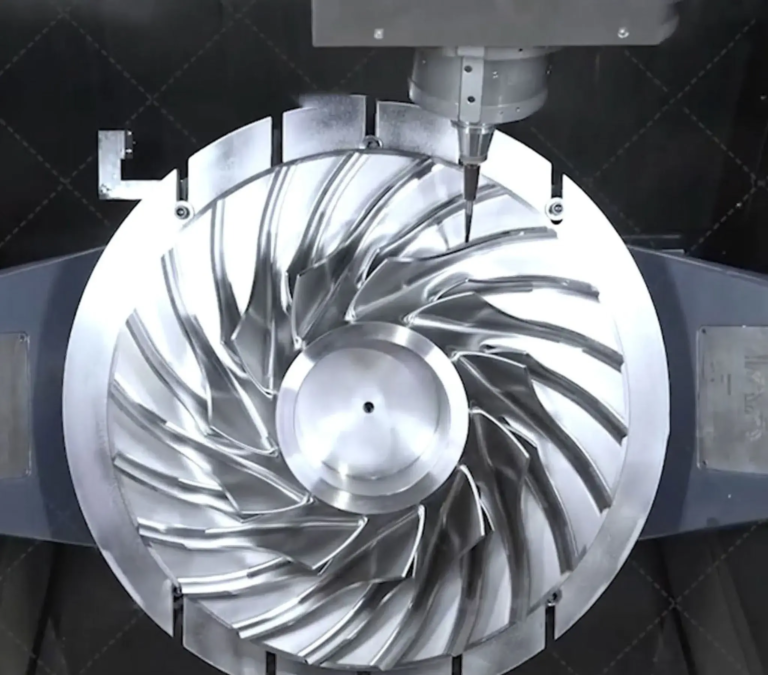

High Precision: The Foundation of CNC Machinery

CNC machine tools are equipped with advanced computer control systems, allowing for precision that is unparalleled in traditional machining methods. This precision enables the creation of complex forms, intricate designs, and precise parts with a level of accuracy that was previously unattainable. The level of precision offered by CNC machining is far superior to traditional machining methods, making it the go-to choice for manufacturers seeking high-quality products.

Great Efficiency: Streamlining the Manufacturing Process

CNC machine tools have revolutionized the manufacturing process by streamlining operations, reducing manual intervention, and increasing efficiency. These machines can automatically complete tasks such as tool positioning, cutting, and processing, significantly reducing labor costs and the risk of human error. With CNC machinies, the programming process can be predefined, allowing for continuous production and reduced treatment time.

High Degree of Automation: Minimizing Human Error

CNC machine tools are characterized by their high degree of automation, which minimizes the need for human intervention. This reduction in human error reduces the risk of mistakes, making it an attractive option for manufacturers seeking high-quality products. The level of automation also enables CNC machines to operate for extended periods without the need for breaks, further streamlining the production process.

High Flexibility: Adapting to Diverse Production Needs

CNC machine tools are highly adaptable, allowing for easy modification of programs to accommodate various production needs. This flexibility enables manufacturers to treat parts of different sizes and shapes, meeting diverse production demands. Additionally, the flexibility of CNC machines makes it possible to adjust production according to changing market demands, allowing for quick turnaround times and reduced costs.

Reducing Material Waste: Efficient Production

CNC machining has been shown to reduce material waste during production. By accurately controlling cutting parameters, CNC machines can optimize material use, resulting in significant cost savings and a lower environmental impact.

Improving Product Quality: Consistent Results

The precision and efficiency of CNC machining enable the production of high-quality products with consistent results. This level of quality is crucial for the production of precision parts, which require exacting tolerances and high-quality surfaces.

Easy Programming and Operation: User-Friendly Interface

Modern CNC machine tools are equipped with user-friendly programming interfaces and operating systems, making it simple for operators to quickly learn and use. This ease of use enables even those without extensive training to start working with CNC machines, streamlining production and reducing the need for expert training.

Reducing Tool Wear: Prolonging Tool Life

CNC machine tools can automatically adjust cutting parameters based on material properties and processing requirements, reducing tool wear and damage, and prolonging tool life.

Improving Production Safety: Reducing Risk

The high degree of automation in CNC machine tools reduces the risk of production accidents, as operators do not need to interact directly with the cutting area. This reduced risk of injury is a significant advantage for manufacturers, making CNC machining a safer option for production.

Easy Integration and Development: Scalability

CNC machine tools can be easily integrated with other automation equipment, forming a complete automated production line. Additionally, the control system can be improved and expanded to meet changing production demands, making CNC machines an attractive option for manufacturers seeking scalability and flexibility.

Reduced Production Costs: Long-Term Savings

Although the initial investment in CNC machine tools may be higher than traditional machine tools, the advantages of high efficiency, automation, and reduced material waste lead to significant long-term cost savings.

Strong Adaptability: Meeting Complex Demands

CNC machine tools can adapt to various complex environments and processing conditions, including different materials, processes, and production batches. This adaptability is a major advantage for manufacturers seeking to produce a wide range of products with varying specifications.

Improve Production Flexibility: Meeting Market Demands

CNC machine tools can quickly adjust production plans in response to changes in market demands, enabling the production of small batches and varying product lines to meet market needs.

Environmentally Friendly: Reduced Noise and Vibration

CNC machine tools can reduce noise and vibration during production, making them a more environmentally friendly option. This reduction in environmental impact is a significant advantage for manufacturers seeking to minimize their ecological footprint.

Fostering Technological Innovation: Driving Progress in Manufacturing

The widespread adoption of CNC machine tools has spurred innovation and development in manufacturing technologies, promoting progress in the industry as a whole.

Improving Business Competitiveness: Unlocking Success

The use of CNC machine tools can improve product quality, reduce production cycles, and decrease production costs, ultimately enhancing business competitiveness in the market.

Supports Complex Form Processing: Unlocking New Possibilities

CNC machine tools can process complex three-dimensional forms, which are challenging or impossible to produce with traditional machine tools or require the collaboration of multiple machines.

Data-Driven Decision Making: Informing Production Decisions

CNC machine tools can collect and store data during the production process, providing valuable insights for production management and decision-making.

Easy Maintenance and Upgrade: Streamlining Operations

Modern CNC machine tools are designed with ease of maintenance and upgrade in mind, making it feasible to perform routine maintenance and upgrade tasks, keeping machines operational and productive.

Improving Employee Skills: Empowering Career Development

CNC machine tools require technical knowledge and skills, encouraging employees to improve their skills and play a positive role in personal career development and overall company technical expertise.

In conclusion, CNC machine tools have revolutionized the manufacturing industry, offering a range of benefits that have transformed production processes and products. With their high precision, high efficiency, and versatility, CNC machines have become an essential tool for manufacturers seeking to stay ahead of the competition. As technology continues to evolve, the importance of CNC machining in modern manufacturing will only continue to grow.