Revolutionizing Manufacturing: The Characteristics of CNC Machining that are Redefining the Industry

In today’s fast-paced and highly competitive manufacturing landscape, companies are constantly seeking ways to improve efficiency, productivity, and quality. One key technology that has emerged as a game-changer in recent years is Computer Numerical Control (CNC) machining. With its ability to precision-control the movement of machine tools and fabricate complex shapes with exceptional accuracy, CNC machining has been transforming the manufacturing industry in various ways. In this post, we’ll delve into the characteristics of CNC machining that are convincing the entire processing industry to adopt this cutting-edge technology.

Accuracy and Precision

CNC machining is renowned for its exceptional accuracy and precision. By using computer-controlled manufacturing processes, CNC machines can produce parts with intricate details and complex shapes with precision heretofore impossible to achieve with traditional manual manufacturing methods. This level of accuracy is particularly crucial in industries such as aerospace, automotive, and medical device manufacturing, where exacting standards are paramount. CNC machining’s ability to deliver high-precision parts has made it an essential tool for producing high-quality products.

Flexibility and Versatility

CNC machining offers unparalleled flexibility and versatility. With the ability to control various types of machine tools, including lathes, milling machines, and grinders, CNC machines can handle a wide range of materials, from metals to plastics and composites. This flexibility enables manufacturers to produce complex parts with varying geometries, weights, and materials, making it an ideal solution for industries with diverse product lines.

Speed and Productivity

CNC machining is renowned for its speed and productivity. By automating the manufacturing process, CNC machines can produce parts at incredible rates, significantly reducing production times and increasing overall efficiency. This is particularly beneficial in industries with high-volume production demands, such as automotive and consumer electronics, where speed is of the essence.

Reduced Labor Costs and Errors

CNC machining minimizes labor costs and errors, two significant concerns in any manufacturing operation. By automating the manufacturing process, CNC machines eliminate the need for extensive labor input, reducing labor costs and minimizing the risk of human error. This results in higher production yields, reduced scrap rates, and increased overall efficiency.

Cost Savings

CNC machining offers significant cost savings compared to traditional manufacturing methods. Without the need for manual intervention, CNC machines can produce parts at a lower cost per unit, making them an attractive option for manufacturers seeking to reduce their production expenses. Additionally, the reduced waste and increased accuracy of CNC machining lead to long-term cost savings through reduced rework and retooling.

Enhanced Quality Control

CNC machining offers unparalleled quality control. By programming the manufacturing process, CNC machines can produce parts with consistent accuracy and precision, reducing the risk of defects and defects. This level of quality control is particularly important in industries where product quality is critical, such as aerospace, medical, and food processing.

Environmental Sustainability

CNC machining is an eco-friendly manufacturing solution. By automating the manufacturing process, CNC machines reduce energy consumption, minimize waste, and promote sustainability. This is particularly relevant in industries with environmentally conscious consumers, such as the packaging and energy sectors, where reducing environmental impact is a key concern.

Innovative Applications

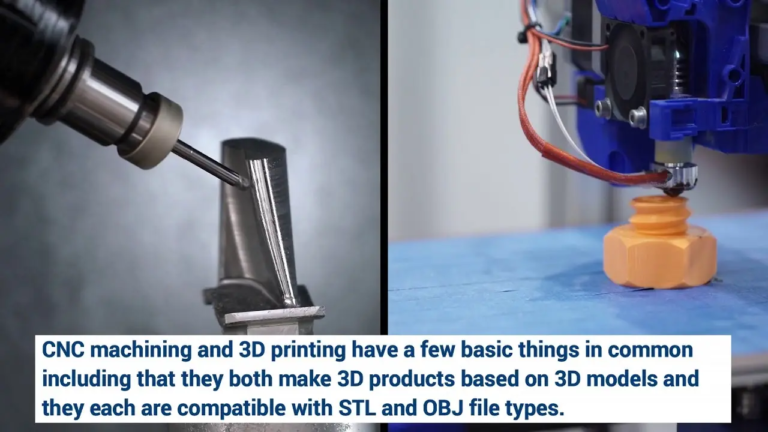

CNC machining is pushing the boundaries of what is possible in manufacturing. With its ability to produce complex shapes and geometries, CNC machines are enabling the creation of innovative products that were previously unattainable. This has led to new applications in fields such as 3D printing, rapid prototyping, and additive manufacturing, further expanding the scope of CNC machining.

Conclusion

In conclusion, the characteristics of CNC machining are revolutionizing the processing industry, enabling companies to produce high-quality parts with exceptional accuracy, precision, and speed. With its flexibility, versatility, and cost savings, CNC machining is an attractive option for manufacturers seeking to optimize their production processes and increase efficiency. As the industry continues to evolve, CNC machining will play a pivotal role in shaping the future of manufacturing, enabling companies to produce innovative products while reducing environmental impact and enhancing product quality.