Mastering CNC drawings: A beginner’s guide

The world of computer numerical control (CNC) processing is huge and complex, with a variety of techniques, techniques and jargon. As a beginner, navigating the world of CNC machinery can be overwhelming. In this article, we will explore the basics of CNC drawings, providing you with a comprehensive guide to understanding and creating these key documents.

What are CNC drawings?

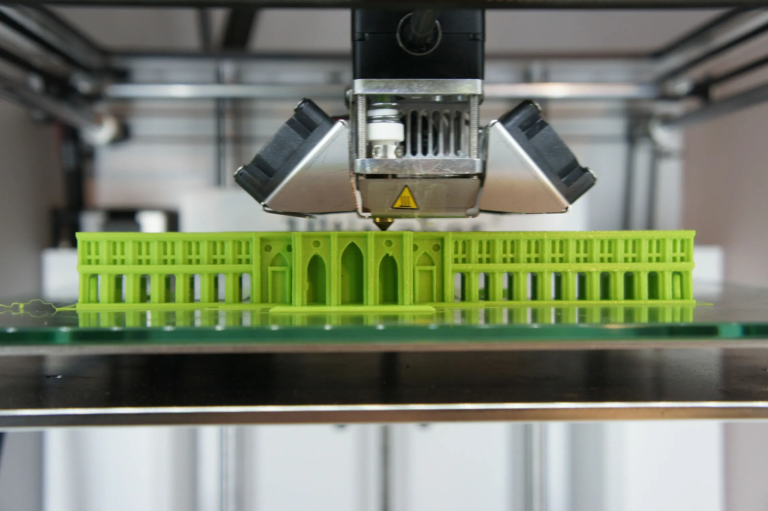

CNC drawings (also known as computer-aided design (CAD) files) are digital blueprints used to convey the specifications of parts or products. They include detailed information on the design, materials and manufacturing process required to create the final product. CNC drawings can take a variety of forms, including two-dimensional (2D) and three-dimensional (3D) models, depending on the software and manufacturer.

Why are CNC drawings important?

CNC drawings are crucial in the manufacturing industry because they ensure accurate communication between designers, engineers and manufacturing teams. They help:

- Prevent errors and misunderstandings

- Simplify the design and production process

- Improve product quality

- Reduce production costs

- Improve efficiency

Basic components of CNC diagrams

A comprehensive CNC diagram usually includes the following components:

- Part Title Block: Contains part name, description and revision number

- Dimension Note: List measurements, tolerances and finishes

- Fabrics and finishes: Describe the material, texture and color code

- Assembly and manufacturing instructions: Detailed description of the production process and assembly requirements

- Tolerance and fit: Provide specifications for tolerance, fit and gaps

Design requirements for CNC drawings

When creating CNC drawings, consider the following design requirements:

- Use consistent and logical naming systems in parts and components

- Use standardized symbols and abbreviations

- Ensure accurate and accurate measurements

- Includes clear and concise notes and legends

- Contains relevant information such as material properties and special requirements

Best practices for creating CNC drawings

To ensure accuracy and efficiency, follow these best practices:

- Create complex designs using CAD software programs with specific functions such as parameter modeling

- Verify designs to detect errors using analysis and verification tools

- Use size and tolerance principles to ensure accuracy

- Coordinate with manufacturing engineers to ensure design manufacturability

in conclusion

Mastering CNC drawings requires a deep understanding of the complexity of design, manufacturing, and communication. By following these guidelines and best practices, beginners can create accurate and effective CNC drawings that ensure successful production and reduce the risk of errors and delays. Remember that a well-designed CNC drawing is essential for successful manufacturing, so take the time to create high-quality drawings to ensure effective and precise production.

FAQs (FAQs)

Q: What are the main differences between 2D and 3D CAD files?

A: 2D CAD files are used for simple two-dimensional designs, while 3D CAD files are used for more complex three-dimensional models.

Q: What is the purpose of the title block in the CNC diagram?

A: The title block provides basic information about the part, such as part name, description and revision number, to aid documentation and communication.

Q: What is the significance of tolerance and suitability for CNC drawings?

A: Tolerances and fittings ensure accurate assembly and manufacturing of parts by providing specifications of tolerances, fits and gaps.

Q: How to ensure the accuracy of CNC drawings?

A: Use CAD software programs with advanced features to verify the design using analysis and verification tools and coordinate with manufacturing engineers to ensure the design is manufacturable.

Q: What are the benefits of using standardized symbols and abbreviations in CNC drawings?

A: Standardized symbols and abbreviations promote clear communication and reduce errors by ensuring consistent terms and symbols.