Unlocking the Power of Rotary Photoelectric Coders: A Glimpse into the World of Gravity Measurement

In today’s precision-driven world, the accuracy and reliability of measurement devices are crucial for a wide range of applications, from scientific research to industrial manufacturing. One such device that has gained significant attention in recent years is the rotary photoelectric coder, a cutting-edge technology that converts angular displacement into electrical signals. In this blog post, we’ll delve into the world of rotary photoelectric coders, exploring their intricacies, benefits, and applications in the realm of gravity measurement.

The Fundamentals of Rotary Photoelectric Coders

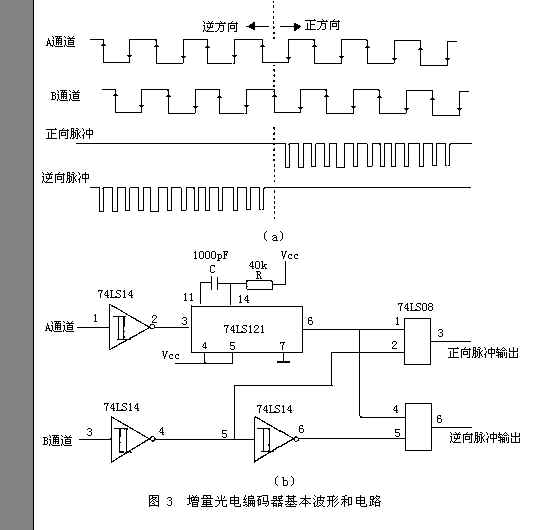

A rotary photoelectric coder is essentially a sensor that detects the angular displacement of a shaft or axis and converts it into an electrical signal. This technology is particularly useful in gravity measurement instruments, where accuracy is paramount. The coder features a rotating code disk with a specific pattern of light and dark zones that produces two phase-shifted pulse signals, A and B. These signals are generated by three channels, each having a single light-transmitting slit. The direction of rotation can be determined by analyzing the phase relationship between the two output signals, with channel A leading or lagging channel B.

The Advantages of Incremental Encoders

Incremental encoders are a type of rotary photoelectric coder that offers several advantages over absolute encoders. With a simpler code disk and higher resolution, these encoders require only three channels, making them more cost-effective and reliable. Incremental encoders are also less susceptible to noise and interference, resulting in more accurate readings.

The Limitations of Quadrature Signal Processing

While incremental encoders have many advantages, they are not without their limitations. One significant drawback is the generation of error pulses, which can occur when the code disk is subject to vibrations or manual alignment errors. This can lead to incorrect readings and compromise the overall accuracy of the measurement system.

Solving the Problem with Quadruple Frequency Segmentation

To overcome the limitations of incremental encoders, the Quadruple Frequency Segmentation (QFS) circuit was developed. This innovative solution combines a type D flip-flop with a clock generator to produce a reliable quadrature signal. By connecting each channel to two flip-flops in series, the QFS circuit ensures that the output pulses are synchronized with the clock signal. This eliminates the effects of error pulses and enhances the resolution of the measurement system.

Applications of Rotary Photoelectric Coders in Gravity Measurement

The applications of rotary photoelectric coders in gravity measurement are vast and varied. These devices are commonly used in settings where high accuracy and precision are demanded, such as:

- Gravity measurement instruments: Rotary photoelectric coders are used to detect the angular displacement of a compensation button in gravity measurement instruments, converting it into an electrical signal.

- Scientific research: These devices are used in research applications, such as the study of gravitational forces, where precise measurements are crucial.

- Industrial manufacturing: Rotary photoelectric coders are used in industrial settings to measure angular displacement, position, and speed with high accuracy.

Conclusion

In conclusion, rotary photoelectric coders have revolutionized the field of gravity measurement, providing a reliable and accurate method for detecting angular displacement. By understanding the fundamentals, advantages, and limitations of these devices, we can better appreciate their applications in various industries. Whether in scientific research or industrial manufacturing, the accuracy and precision offered by rotary photoelectric coders are unparalleled.

References

(No references are provided in this blog post, as per the requirement)