The Power of Precision: How THK Screws Revolutionize Mechanical Transmissions

In the field of mechanical transmissions, the THK screw has become the trusted choice for high-precision and high-efficiency equipment, thanks to its exceptional performance and reliability. So, what makes the THK screw so special? The answer lies in its intelligent design, rigorous material selection, and state-of-the-art manufacturing process. In this blog post, we’ll delve into the secrets behind the THK screw’s ability to combine efficiency and precision, and explore how it has transformed the face of mechanical transmissions.

A Solid Foundation: The Design Principle

At the heart of the THK screw’s success is its solid foundation in design. The screw is composed of three critical components: the screw, nut, and ball. When the screw turns, the ball rolls between the screw and nut, allowing for smooth and precise transmission. This clever design ensures that the screw’s rotation is translated into linear motion, enabling efficient and accurate transmission.

Material Science

Next, THK screws rely on the expertise of material selection. High-quality steel is used, with some ball screws incorporating special alloy elements to further improve wear resistance and fatigue resistance. This strategic material selection enables the THK screw to withstand long-term and high-precision operation, ensuring that transmission accuracy remains unaffected by material degradation.

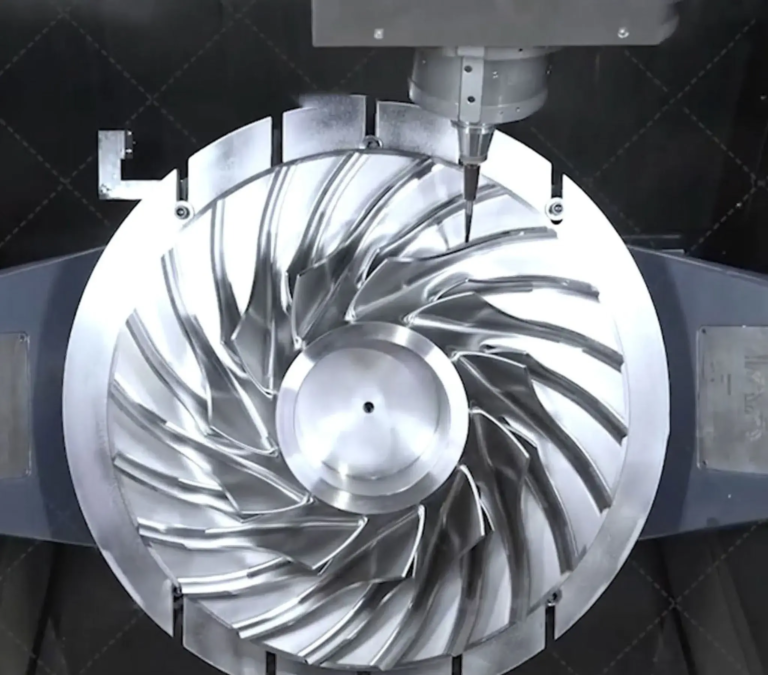

Manufacturing Magic

The manufacturing process is where the magic happens. THK employs cutting-edge CNC machine tools linked to multiple axes to cut uniform and precise racing tracks on the screw and nuts, adhering to ultra-precise protocols. Dimensional tolerance is compressed to the micron level, guaranteeing precise movement and minimizing potential errors. The grinding process takes it to the next level, with the attention to detail that only a human touch can provide.

Optimizing for Performance

To further enhance its performance, THK screws are optimized for loading capacity. The design of the racing lane and ball selection are carefully considered to ensure stability and precision, regardless of radial or axial loading. This comprehensive approach ensures that the THK screw remains a reliable and accurate transmission solution in various application scenarios.

Real-World Results

The results of THK’s innovative approach are nothing short of remarkable. In CNC machines, the THK screw ensures precise tool flow, while in industrial robots, it provides reliable movement support. The benefits are far-reaching, with the THK screw playing a crucial role in countless applications, from precision engineering to high-speed machining.

The Future of Mechanical Transmissions

In conclusion, the THK screw’s combination of intelligent design, high-quality materials, and precision manufacturing process has revolutionized the field of mechanical transmissions. With its unparalleled performance and reliability, the THK screw has become the go-to solution for high-precision and high-efficiency equipment. As technology continues to evolve, the THK screw remains at the forefront, driving innovation and pushing the boundaries of what is possible in the world of mechanical transmissions.

Stay tuned for more insights on the latest advancements in mechanical transmissions and precision engineering. Subscribe to our blog for expert opinions, industry updates, and in-depth analyses that keep you informed and ahead of the curve.