The Unveiling of CNC Machine Tools and CNC Milling: A Comprehensive Guide

In today’s fast-paced manufacturing landscape, Computer Numerical Control (CNC) machine tools and CNC milling machines have become indispensable assets for production companies. These advanced machines have revolutionized the manufacturing industry by offering high-precision, efficient, and cost-effective solutions for various applications. In this article, we’ll delve into the world of CNC machine tools and CNC milling, exploring their similarities, capabilities, and future prospects.

Similarities and Differences

While CNC machine tools and CNC milling machines share many similarities, there are some key differences between them. CNC machine tools are precision machines that use a CNC system to control their movements and perform various tasks, whereas CNC milling machines are a type of CNC machine specifically designed for milling and cutting operations. Both machine tools and milling machines are equipped with sophisticated CNC systems that convert programmed instructions into action, ensuring precise and repeatable results.

How They Work

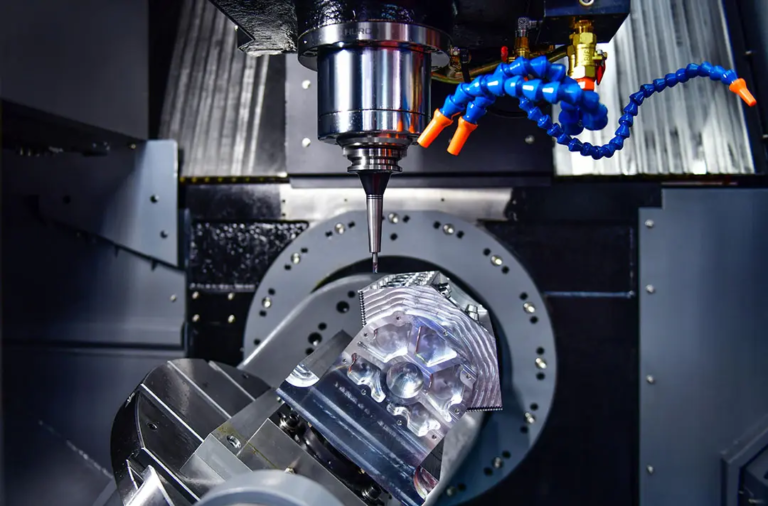

The CNC system is the heart of both CNC machine tools and CNC milling machines. It receives the machining program and converts it into action instructions for the machine tool, allowing it to perform automatic processing. The machining program is written in code G or M, describing the machining path, tool selection, and part setting. The servomotor, a crucial component of CNC machines and milling machines, accurately controls the movement of each axis to achieve high precision machining.

Structural Components

CNC machine tools and CNC milling machines share similar structural components, including:

- Frame: The frame of CNC machine tools and milling machines is designed to provide stability and support during operation.

- Rail guide: High-precision guides, such as linear guides or ball guides, ensure the accuracy of machine movement.

- Pin: Pins are used to install tools or accessories, with adjustable speed and torque for optimal performance.

- Tools: Both machine tools and milling machines utilize various types of tools, such as end mills, drills, and slotting tools.

- Workbench: The workbench is used to correct parts and perform various operations, such as translation, rotation, and clamping.

Treatment Capacities

CNC machine tools and CNC milling machines boast impressive treatment capacities, including:

- High precision: Both machine tools and milling machines offer high-precision machining capabilities, suitable for a wide range of applications.

- High efficiency: Automatic tool change, supply, and other operations significantly improve processing efficiency.

- Complex machining: CNC machines and milling machines can perform complex operations, such as milling, turning, and grinding.

- Multi-axis machining: Some machine tools and milling machines feature multi-axis capabilities, enabling linked machining of five or more axes.

Applications

CNC machine tools and CNC milling machines find applications in various industries, including:

- Machine manufacture: These machines are widely used in mechanical manufacturing, construction, and repair shops.

- Electronics: CNC machine tools and milling machines are applied in electronics, such as the manufacture of precision components, electronic shells, and other products.

- Medical devices: These machines are employed in the production of high-precision medical parts, surgical instruments, and other medical equipment.

- Manufacture of crafts: CNC machine tools and milling machines are used to process complex shapes and forms in various craft industries, such as sculpture and decoration.

Future Prospects

The future of CNC machine tools and CNC milling machines holds much promise, with advancements in technology and innovation leading to:

- Higher-speed processing: Machines will continually improve processing speed to meet the demands of the high-efficiency market.

- Intelligent control systems: CNC systems will become more intelligent, enabling adaptive control and defect diagnosis.

- Green manufacturing: The focus will shift towards environmentally friendly design and manufacturing practices, minimizing energy consumption and noise reduction.

- Personalization: As market demand diversifies, the degree of personalization in CNC machine tools and milling machines will increase to cater to individual customer needs.

Maintenance and Maintenance

To ensure optimal performance, CNC machine tools and CNC milling machines require regular:

- Inspection: Regular inspections should be performed on guide rails, pins, tools, and other components.

- Cleaning and maintenance: Machines must be regularly cleaned and maintained to prevent the buildup of metal fleas, coolants, and other contaminants.

- Software upgrade: CNC systems must be regularly updated to meet new processing needs and improve machining efficiency.

- Troubleshooting: Defects may arise during use, requiring prompt identification and resolution to minimize downtime.

In conclusion, CNC machine tools and CNC milling machines share many characteristics, capabilities, and applications. As technology continues to advance, these machine tools and milling machines will become even more efficient, intelligent, and environmentally friendly, making significant contributions to the modern manufacturing industry.