As manufacturing continues to grow, the demand for innovative and effective production methods has become more important than ever. One of the key strategies used to achieve this is to use advanced computer numerical control (CNC) machining. Austin CNC machining has become a leader in the field, offering a range of benefits that are changing the way business is made.

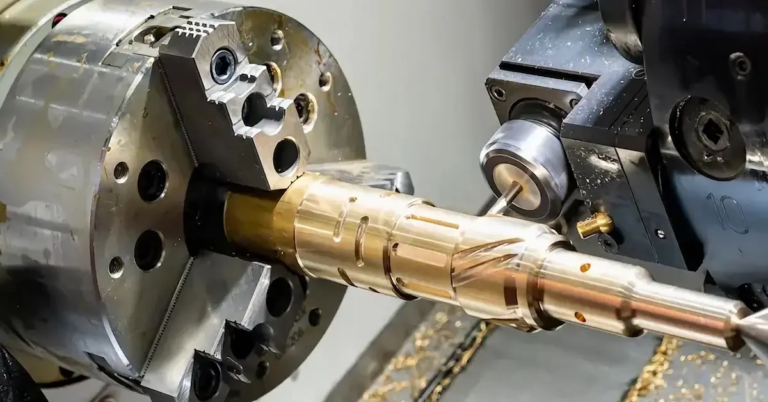

The core of CNC machining involves the use of computer-controlled machines to perform precise machining operations such as milling, rotation and grinding. This technology allows for the production of complex parts and components with previously impossible accuracy and speed. In the past, precision processing was a time-consuming and labor-intensive process that required a lot of manual labor and professional skills. However, with the advent of CNC machining, manufacturers can now produce high-quality parts with minimal human intervention, resulting in substantial cost savings and increased efficiency.

One of the most important benefits of Austin CNC machining is its ability to produce complex parts with unparalleled precision. This is achieved by using advanced computer software and complex machinery that jointly control the cutting process and ensure that the parts are generated in exact specifications. This accuracy is particularly important in industries such as aerospace, automotive and healthcare, where component failures can have serious consequences.

In addition to accuracy, Austin CNC machining offers a range of other benefits, including increased productivity and reduced production costs. By automating the manufacturing process, companies can reduce the need for manual labor, cut costs and free up resources for other important tasks. This increased productivity also enables manufacturers to produce parts at a faster rate, allowing them to meet growing demand and maintain a competitive lead.

Another advantage of Austin CNC machining is its ability to highly customize complex parts. This is especially important for businesses that require unique or professional components, as it allows them to produce parts that suit their specific needs. Whether it is complex medical implants, precision aircraft parts, or customized vehicle components, Austin CNC machining is able to produce parts that meet the highest standards of quality and accuracy standards.

With the continuous development of manufacturing, it is obvious that CNC processing will play an increasingly important role in the production process. Austin CNC machining is revolutionizing how businesses are approaching manufacturing by being able to produce complex parts with unparalleled precision. Whether you are a manufacturer, engineer or business owner, you must understand the benefits and capabilities of Austin CNC machining, as it has the potential to change the way you produce.

FAQ:

Q: What is CNC machining and how does it work?

A: CNC machining is a process that uses a computer-controlled machine to perform precise machining operations such as milling, rotation and grinding. The process involves the use of a computer program to control the movement of the machine so that precise, accurate cuts can be performed.

Q: What are the benefits of Austin CNC processing?

A: The benefits of Austin CNC processing include improved accuracy, reduced production costs and increased productivity. It also allows for the production of complex parts with highly customization.

Q: Which industries benefit from Austin CNC processing?

A: Several industries benefit from Austin CNC processing, including aerospace, automotive, healthcare, etc. Any industry that requires precise parts or complex components can benefit from this technology.

Q: Is CNC processing suitable for small and medium-sized enterprises?

A: Yes, CNC machining is suitable for small and medium-sized enterprises because it saves a lot of cost and improves efficiency compared to traditional manufacturing methods.

Q: What is the future of CNC processing in manufacturing?

A: The future of CNC machining in the manufacturing industry is promising, and advances in technology and software allow for higher accuracy and automation improvements. With the continuous development of the industry, CNC processing may play an increasingly important role in production.