Algebraic CNC machining: a new boundary for precise manufacturing

In today’s fast-paced manufacturing environment, accuracy and efficiency are more important than ever. The demand for high-quality, customizable parts is rising, and CNC machining has become a key solution to meet this demand. Among all types of CNC machining, algebraic CNC machining has recently attracted great attention due to its unparalleled accuracy and flexibility. In this article, we will explore the world of algebraic CNC machining, exploring the benefits, applications and new boundaries it represents in precise manufacturing.

What is algebraic CNC machining?

Algebraic CNC machining is a computer numerical control (CNC) machining that uses advanced mathematical algorithms to program and control the machining process. This technology combines the accuracy of computer-aided design (CAD) and computer-aided manufacturing (CAM) to create complex parts with unparalleled precision.

Benefits of Algebraic CNC machining

The benefits of algebraic CNC machining are many:

- Improve accuracy: Algebraic CNC machining is able to produce parts with higher accuracy, accuracy and surface finish due to the involvement of advanced mathematical algorithms.

- Complex part manufacturing: This technology allows the manufacture of complex parts with complex functions, such as the Helix>Appendix to indicate precise manufacturing.

- Improve efficiency: Automatic tool changes and optimized machining strategies reduce production time and costs.

- Enhanced customization: Algebraic CNC machining is able to produce customized parts with high precision to meet specific needs in industries such as aerospace, automotive and medical care.

Application of algebraic CNC machining

The applications of algebraic CNC machining are huge and diverse:

- Aerospace and Defense: Algebraic CNC machining is used in the production of aircraft parts, satellite components and defense equipment.

- Medical equipment: Accurate processing is essential for the manufacturing of medical equipment such as implants, surgical instruments and diagnostic equipment.

- car: Algebraic CNC machining is used for the production of engine components, transmission parts and other precise automotive components.

- Industrial Equipment: This technology is used to manufacture precision equipment such as pumps, valves and gears.

in conclusion

Algebraic CNC machining is a game changer in the field of precision manufacturing, providing unparalleled accuracy, efficiency and customization. With the demand for high quality and complex parts continue to grow, algebraic CNC machining will play an increasingly important role in meeting this demand. From a good point of view, we are committed to keeping the forefront of this technology and providing our customers with the latest and most accurate manufacturing solutions.

FAQ

- What is the difference between algebraic CNC machining and traditional CNC machining?

Algebraic CNC machining uses advanced mathematical algorithms to program and control the machining process, while traditional CNC machining relies on G-code programming.

- What are the main benefits of algebraic CNC machining?

Benefits include improved precision, complex part manufacturing, improved efficiency and enhanced customization.

- What are the common applications of algebraic CNC machining?

Some common applications include aerospace, medical equipment, automotive and industrial equipment manufacturing.

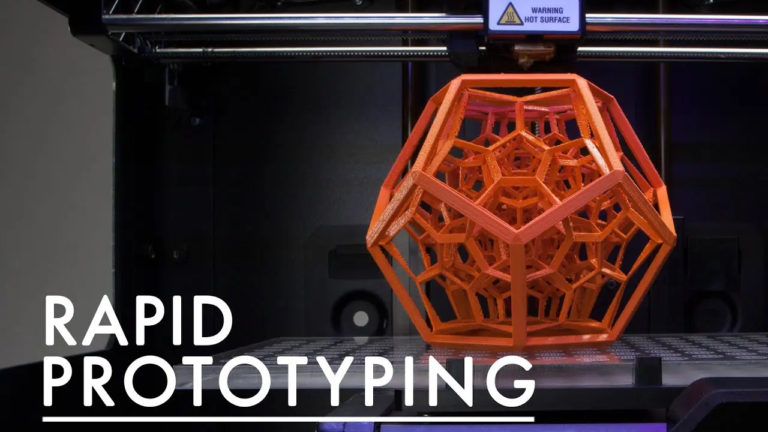

- How does algebraic CNC machining compare with 3D printing?

Algebraic CNC machining can be used to produce precise, precise parts, while 3D printing is more suitable for large-scale production efforts.

- Can excellent light provide customized precision machining services?

Yes, Great Light is a professional five-axis CNC machining manufacturer that provides customized precision machining and one-stop post-processing and completion services.