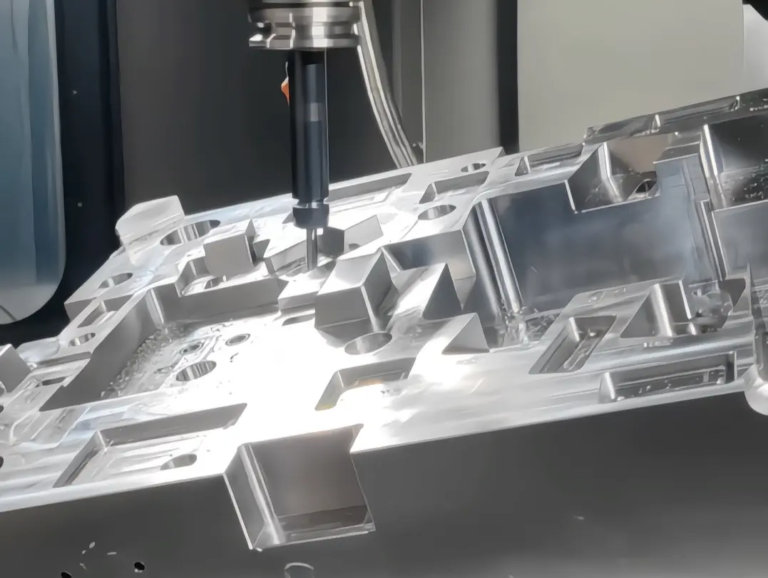

With the increasing automation of manufacturing, AI-driven CNC machining has reached new heights, revolutionizing the way we produce complex parts and components. With the rise of advanced technologies such as AI, machine learning, and data analytics, five-axis CNC machining has become more efficient, precise and cost-effective than ever before.

To produce high-quality parts quickly and cost-effectively, five-axis CNC machining has been a game-changer for industries such as aerospace, automotive and medical care. This technology allows manufacturers to create complex parts accurately and accurately, ensuring compliance with required standards.

The advent of AI-powered CNC machining has brought some benefits, including:

- Improved Accuracy: AI-driven CNC machining relies on sophisticated algorithms and sensors to detect and correct any deviations from design specifications, ensuring that the final product meets the required standards.

- Improve efficiency: AI can analyze data in real time and optimize production processes, thereby reducing production cycle time and increasing output.

- Enhanced Accuracy: AI-driven CNC machining can also produce high-precision parts that can create complex and detailed designs even in complex geometries.

- Real-time monitoring and control: AI-driven CNC machining allows real-time monitoring and control of the production process, allowing manufacturers to adjust as needed to ensure high-quality parts are produced.

From a good point of view, we are committed to keeping the forefront of AI-driven CNC machining technology, investing in the latest equipment and training our teams to ensure they are well versed in these cutting-edge systems. Our expertise and experience in five-axis CNC machining enables us to produce complex parts accurately and accurately to meet the needs of customers in various industries.

In short, AI-driven CNC machining revolutionizes the manufacturing landscape, thereby improving accuracy, efficiency and accuracy. As a leading CNC machining manufacturer, we enjoy the greatest lighting commitment to bringing these advancements to our customers with high quality parts and components.

FAQ:

Q: What is AI-driven CNC machining?

A: AI-driven CNC machining is a use of artificial intelligence (AI) and machine learning (ML) algorithms to detect and correct any deviation from design specifications to ensure any deviation from high-quality parts are generated.

Q: How to improve accuracy in AI-driven CNC machining?

A: AI-driven CNC machining relies on sophisticated algorithms and sensors to detect and correct any deviations from design specifications to ensure that the final product meets the required standards.

Q: What are the benefits of AI-driven CNC machining?

A: The benefits of AI-driven CNC machining include increased accuracy, increased efficiency and improved accuracy, allowing manufacturers to produce high-quality parts quickly and cost-effectively.

Q: Can I get custom parts through AI-powered CNC machining?

A: Yes, AI-powered CNC machining can produce custom parts with complex geometric shapes and configurations, making it an ideal solution for companies that need unique or custom parts.