Revolutionizing Tool Manufacturing: The Breakthrough of IVAG Laser Machining Center

In an era where technology is rapidly evolving, the quest for innovation in tool manufacturing has reached new heights. The introduction of IVAG laser machining center has catapulted the industry to unprecedented levels of precision, efficiency, and versatility. This revolutionary technology has effectively overcome the challenges of treating superhard materials, opening doors to a new frontier of tool production.

Superhard materials, such as aluminum alloys, composite materials, and polycrystalline diamond tools (PCD), coating tools (CVD), and cubic boron nitride tools (CBN), have long been a challenge for traditional grinding manufacturing processes. The three-dimensional surface treatment of these materials has been a costly and time-consuming process, leaving little room for innovation. However, the IVAG laser machining center has changed the game by providing a viable solution for the treatment of these superhard materials.

The Power of Laser Technology

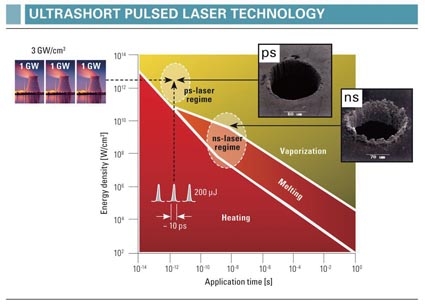

Laser technology has been touted as a game-changer in the world of tool manufacturing. The IVAG laser machining center harnesses the power of pulses to deliver unparalleled precision and efficiency. By cutting diamond particles directly, this technology eliminates the need for additional coating and significantly reduces production time. The result is a product that is not only more precise but also more cost-effective.

Advantages of IVAG Laser Machining Center

The IVAG laser machining center boasts a range of advantages that set it apart from traditional manufacturing methods. Some of the key benefits include:

- Clean production and low operating costs: The laser machining center is designed to minimize waste and reduce operating costs. With no cutting force generated during treatment, it eliminates the need for a cooling system and decontamination.

- Increased tool lifespan: The IVAG laser machining center can significantly prolong the lifespan of tools, making it an attractive option for manufacturers seeking to reduce production costs.

- Three-dimensional surface treatment: The IVAG laser machining center can treat complex surfaces with ease, allowing for the creation of intricate tools with precision and accuracy.

The Future of Tool Manufacturing

As the industry continues to evolve, the IVAG laser machining center is poised to play a significant role in shaping the future of tool manufacturing. With its ability to treat superhard materials and deliver unparalleled precision and efficiency, this technology is expected to revolutionize the way we approach tool production.

Expert Insights

In a recent interview, Christoph Plüss, a leading expert in the field of laser technology, shed light on the future of tool manufacturing. "The use of laser technology to treat diamond tools has made significant strides in product quality, production efficiency, and treatment variety. Laser machining technology is essential for each tool manufacturer who wants to succeed in the future market."

Conclusion

The IVAG laser machining center has ushered in a new era of innovation in tool manufacturing. With its cutting-edge technology and precision capabilities, this machine is poised to transform the industry. As the demand for precision and efficiency continues to grow, the IVAG laser machining center is perfectly positioned to meet the challenge head-on. Stay tuned for the latest developments in this exciting field as we continue to push the boundaries of what is possible in tool manufacturing.