Precision engineering of CNC machining

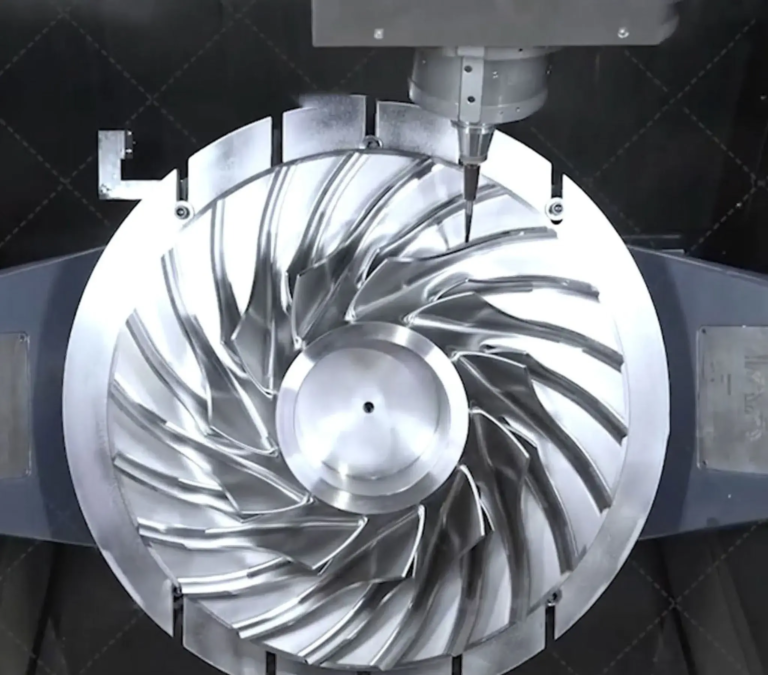

In today’s fast-paced world of manufacturing, precision is key. Companies are looking for ways to improve quality, reduce costs and increase efficiency. One way to achieve this is to use CNC machining, a subtractive manufacturing process that uses a computer-controlled machine to remove materials from inventory to create the final product. In this blog post, we will dig into the world of CNC machining and explore its applications, benefits and limitations.

What is CNC machining?

CNC machining is a manufacturing process that uses computer-controlled machines to eliminate human errors and improve accuracy. The process involves three main components: a computer-aided design (CAD) program, a computer numerical control (CNC) machine, and a cutting tool. The CAD program creates a digital model of the parts, while the CNC computer interprets the program and makes the necessary adjustments to create the final product.

Benefits of CNC machining

CNC machining offers a variety of benefits, including:

- accurate: CNC machining can accurately control the manufacturing process, resulting in high-quality products.

- speed: CNC computers can run 24/7, reducing production time and improving efficiency.

- flexibility: CNC machines can be programmed to generate parts from small to large, from simple to complex geometric shapes.

- Cost-effective: CNC machining reduces labor costs and waste, making it a cost-effective choice for manufacturing.

Application of CNC machining

CNC machining is used in a variety of applications, including:

- aerospace: CNC machining high-precision parts used to produce aircraft and spacecraft.

- Medical: CNC processing is used to produce medical equipment, implants and prosthetics.

- car: CNC machining is used to produce parts for cars, trucks and other vehicles.

- Industrial: CNC machining is used to produce mechanical parts, tools and equipment.

Limitations of CNC machining

Although CNC machining is a powerful manufacturing process, it has limitations. Some of these limitations include:

- Tool wear: CNC machines require regular maintenance to ensure optimal performance.

- Substance restrictions: CNC processing is best suited for certain materials such as metals and plastics.

- Security Question: If not operated correctly, the CNC machine can be dangerous.

- Software Restrictions: CAD programs can be complex and require a lot of training to be used effectively.

in conclusion

CNC machining is a powerful manufacturing process that provides precision, speed and flexibility. Despite its limitations, CNC machining is an invaluable tool for producing high-quality parts in a variety of industries. Perfect for us, we specialize in five-axis CNC machining and provide one-stop post-processing and completion services. With our advanced equipment and experienced team, we can help you produce customized precision parts at the best prices.

FAQ

Q: What is CNC processing?

A: CNC machining is a material that uses a computer-controlled machine to remove materials from inventory to create the final product.

Q: What are the benefits of CNC processing?

A: CNC machining provides accuracy, speed and flexibility, reduces production time and improves efficiency.

Q: What is the application of CNC processing?

Answer: CNC processing is used in aerospace, medical, automotive and industrial industries, etc.

Q: What are some limitations of CNC processing?

A: CNC machining has limitations, including tool wear, material limitations, safety issues and software limitations.

Q: How to start CNC processing?

A: Contact us to learn more about our five-axis CNC machining service and how we can help you produce custom precision parts at the best prices.