The Evolution of Metal Treatment: A New Era of Precision and Efficiency

In the modern industrial landscape, the world of metal treatment has witnessed a remarkable revolution, giving rise to innovative solutions that have transformed the way we approach processing and shaping metals. As a luminary in this field, the humble mandrel has long been a cornerstone of metal treatment, with traditional methods ranging from manual to hydraulic and pneumatic. However, these conventional approaches often fall short, leading to inconsistencies, inefficiencies, and reduced product quality.

The Limitations of Traditional Mandrels

Traditional mandrels, be they manual or hydraulic, often rely on tried-and-true designs, such as four-sludge shades or three-sludge chucks with special claws. While these solutions may appear straightforward, they can be woefully inadequate when confronted with products of varying sizes or shapes. For instance, when handling a square piece, a four-jaw hydraulic chuck may struggle to maintain uniform grip, leading to inconsistent pressure and potential damage to the material. Similarly, manual chucks, though offering some adjustability, can be time-consuming and labor-intensive to operate.

The Emergence of a New Era of Mandrels

In recent years, however, a new breed of mandrels has emerged, promising to revolutionize the metal treatment landscape. One such innovation is the hydraulic mandrel with adjustable jaws, capable of accommodating a wide range of products, from the standard to the unconventional. This game-changing design enables precise control over jaw positioning, permitting the handling of diverse shapes and sizes with ease and accuracy.

A Closer Look at the Innovative Mandrel Design

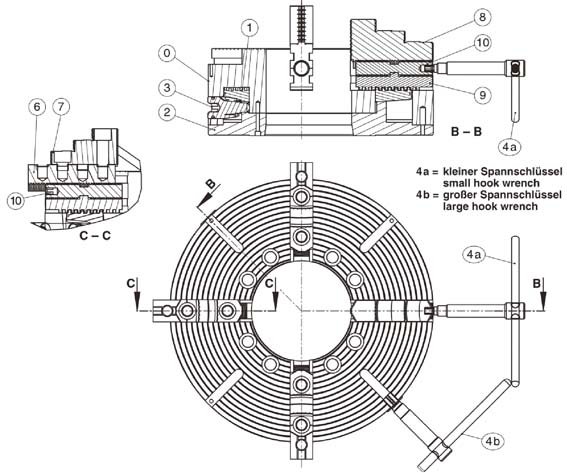

The hydraulic mandrel in question features a jaw design with four adjustable jaws, specifically engineered to adapt to various product shapes and sizes. This unique feature allows for precise control over each jaw, ensuring optimal grip and tension, even when working with complex or irregularly shaped materials. This design can be seen in Figure 4, which illustrates the mandrel’s flexible configuration.

Benefits of the Innovative Mandrel Design

The advantages of this cutting-edge mandrel design are multifaceted:

- Accuracy: With its adjustable jaws, this mandrel ensures precise gripping and positioning, resulting in improved accuracy and reduced risk of material damage.

- Efficiency: The hydraulic drive system enables rapid and effortless adjustment, streamlining the metal treatment process and minimizing labor costs.

- Flexibility: The mandrel’s adaptability to various product shapes and sizes broadens its applications, making it an ideal solution for manufacturers working with diverse materials.

- Durability: The mandrel’s robust construction and maintenance-friendly design ensure a prolonged lifespan, reducing the need for frequent replacements and minimizing downtime.

A Glimpse into the Future of Metal Treatment

The advent of this innovative mandrel design marks a significant milestone in the evolution of metal treatment. As the industry continues to evolve, we can expect even more groundbreaking solutions that will reshape the way we process and shape metals. By embracing these advancements, manufacturers can anticipate improved product quality, increased efficiency, and enhanced profitability.

Conclusion

The dawn of a new era in metal treatment is upon us, and it is clear that the humble mandrel has evolved to become a powerful tool in the hands of manufacturers. With its unparalleled precision, efficiency, and flexibility, this innovative design is poised to revolutionize the way we approach metal treatment, ushering in a future of increased productivity, reduced waste, and optimized product quality. As we move forward, it is imperative that manufacturers remain at the forefront of this evolution, embracing cutting-edge solutions that will propel their businesses to new heights.