The Future of Transmission Technology: How Laser Welding is Revolutionizing the Industry

The transmission technology landscape is undergoing a significant transformation, driven by the increasing demand for variable speeds and the need to reduce fuel consumption and emissions. In this rapidly evolving landscape, innovation is key, and one cutting-edge technology that is helping to shape the future of transmission manufacturing is laser welding.

At the forefront of this revolution is Dr. Andreas Mootz, President of Emak Automation Co., Ltd., based in Hoybach, Germany, who has been at the helm of technical development for production laser welding. In an exclusive interview, Dr. Mootz shared his insights on the role of laser welding in the transmission industry and its potential to transform the way we manufacture transmission components.

A New Era of Transmission Technology

Traditionally, transmission components were manufactured using a combination of machining, pressing, and welding processes. However, advances in laser technology have changed the game, allowing for more efficient and precise production. "Laser welding is one of the most important innovations in the field of transmission production," Dr. Mootz noted. "It’s an integrated process that combines various steps into one efficient and high-precision production process."

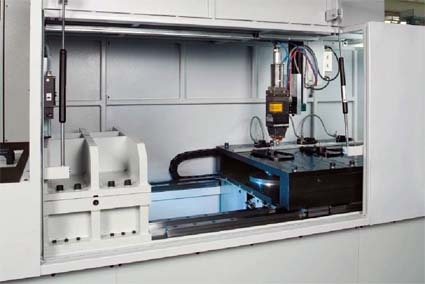

The ELC 160, a cutting-edge laser welding machine from Emak, is a prime example of this technology in action. With its three stations, including preheating, pressing, and welding, the machine is capable of processing transmission gears with unparalleled speed and precision. "The ELC 160 is a game-changer for transmission manufacturing," Dr. Mootz said. "It’s a testament to the power of innovation and the benefits it can bring to the industry."

A Greener Future for Transmission Technology

As the transmission industry continues to evolve, there is a growing need for more efficient and environmentally friendly production methods. Laser welding is perfectly positioned to meet this challenge, as it can reduce energy consumption by 8% compared to traditional methods. "Laser welding is an eco-friendly solution that not only reduces production costs but also minimizes its carbon footprint," Dr. Mootz explained.

The ELC 160 is designed to integrate different production processes, including pressing and welding, into a single, efficient, and versatile machine. This not only streamlines production but also reduces energy consumption, making it an attractive solution for manufacturers looking to reduce their environmental impact.

The Future is Bright

As the transmission industry continues to evolve, one thing is clear: demand for variable speeds will only continue to grow. "The trend is clear," Dr. Mootz noted. "The future of transmission technology is all about efficiency, precision, and environmental sustainability."

Emmak’s ELC range is perfectly positioned to meet this demand, offering a range of laser welding solutions designed to cater to the needs of manufacturers worldwide. With its wealth of experience in producing transmission components and its technical expertise, Emmak is well-equipped to lead the way in the development of this cutting-edge technology.

Conclusion

The future of transmission technology is here, and it’s bright. With advanced laser welding solutions like the ELC 160, manufacturers can reduce their environmental impact, improve production efficiency, and create high-quality transmission components that meet the needs of a rapidly changing industry. As the world leader in laser welding, Emmak is at the forefront of this revolution, working closely with its customers to develop innovative solutions that shape the future of transmission manufacturing.