The Precision and Innovation of Hiwin Ball Screws: Revolutionizing Precision Motion Control

In today’s high-tech world, precision and accuracy are the keys to success in various industries, from robotics and automation to aerospace and more. To achieve these demanding standards, manufacturers are constantly seeking innovative solutions that can provide exceptional performance and reliability. This is where Hiwin ball screws come in – a game-changing technology that has revolutionized precision motion control. In this blog post, we will delve into the characteristics and applications of Hiwin ball screws, showcasing their impressive capabilities and the benefits they bring to various industries.

What are Hiwin Ball Screws?

Hiwin ball screws are a type of precision screw product designed for high-precision motion control systems. Unlike traditional lead screws, Hiwin ball screws utilize a unique design featuring balls instead of threads, allowing for smoother and more precise movement. This innovative technology has made them an essential component in various industries, particularly in robotics, precision machinery, and automation.

Key Characteristics of Hiwin Ball Screws

So, what sets Hiwin ball screws apart from traditional lead screws? Here are their exceptional characteristics:

- High Precision: Hiwin ball screws offer unparalleled precision, thanks to their reliable tracking and minimal wobble. This ensures consistent and precise movement, even under heavy loads.

- Smooth Motion: The ball screw’s smooth, low-friction movement reduces vibration and noise, making it ideal for applications that require silent operation.

- High Torque: With a high torque-to-weight ratio, Hiwin ball screws can withstand heavy loads and generate impressive force, making them suitable for demanding applications.

- Long Lifespan: The durable design and minimal maintenance requirements of Hiwin ball screws ensure a longer lifespan and reduced downtime.

Applications of Hiwin Ball Screws

Hiwin ball screws have become a staple in various industries, including:

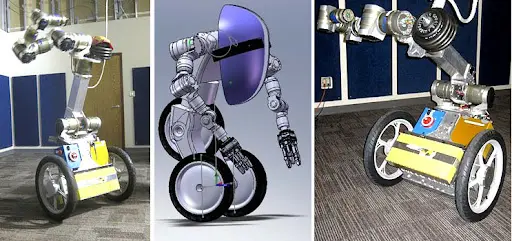

- Robotics and Automation: Hiwin ball screws are used in robotic arms, grippers, and other precision mechanisms, enabling smooth and accurate movement.

- Aerospace and Defense: Due to their high precision and reliability, Hiwin ball screws are utilized in aircraft, spacecraft, and defense systems.

- Medical and Biomedical: The high-precision movement of Hiwin ball screws is critical in medical devices, such as surgical robots, prosthetics, and implantable devices.

- Precision Machinery: Hiwin ball screws are used in precision machinery, like CNC machines, laser cutters, and other high-precision equipment.

- Motorized Stage Systems: Their smooth motion and precision make Hiwin ball screws ideal for motorized stage systems, used in various applications, such as inspection, material processing, and more.

Benefits of Hiwin Ball Screws

By incorporating Hiwin ball screws into your systems, you can expect numerous benefits, including:

- Increased Precision: Achieve exceptional accuracy and precision, reducing errors and variability.

- Improved Performance: Enjoy smoother, quieter, and more efficient operation.

- Longer Lifespan: Benefit from reduced maintenance and extended lifespan, minimizing downtime and costs.

- Increased Versatility: Adapt to various applications, from small-scale to large-scale production, with ease.

Conclusion

Hiwin ball screws have revolutionized precision motion control, offering unparalleled precision, smooth motion, high torque, and durability. Their applications range from robotics and aerospace to medical and biomed, and precision machinery. By incorporating Hiwin ball screws into your systems, you can expect increased precision, performance, and lifespan. As technology continues to evolve, the importance of Hiwin ball screws will only continue to grow, driving innovation in various industries and shaping the future of precision motion control.