Revolutionizing Coating Technology: Hauzer’s Breakthrough in Friction Reduction and Wear Protection

Introduction

As the world grapples with the challenges of climate change, reducing CO2 emissions is a top priority. In the automotive industry, one of the most effective ways to achieve this is by reducing friction and improving wear protection through advanced coating technologies. Hauzer, a leading player in the development of advanced coatings, has made a significant breakthrough in this area with the launch of the HAUZERFLEXICOAT 1200 device and TA-C configuration.

The Need for Advanced Coatings

Traditional DLC (Diamond-Like Carbon) coatings have reached their limits, with working temperatures and loading densities increasing. The classic CRN coatings used in this application have a high friction coefficient, leading to high fuel consumption and CO2 emissions. The industry is moving towards smaller additives to modify material lubrication properties and reduce viscosity, making anti-wear protection more important than ever.

The HAUZERFLEXICOAT 1200 Device and TA-C Configuration

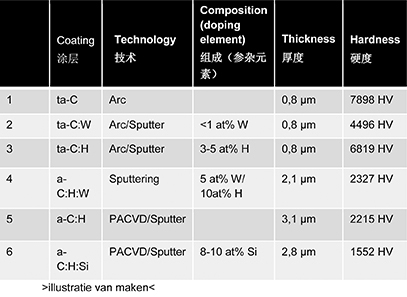

The HAUZERFLEXICOAT 1200 device is a physical vapor deposition (PVD) system that uses a hybrid deposition technology, including a steam braiding method for depositing the magnetron sputtering and closed-cycle magnetron sputtering. The device is equipped with four magnetron spray cathodes (CR, WC, C) and a set of circular arc cathodes (C). This innovative technology allows for the production of six different coatings, as shown in Table 1.

The substrate is coated at high speed, polished to a diameter of 30 mm and a rough base of 15 nm. This ensures a high-quality surface finish, essential for optimal performance.

Post-Coating Processing

The arc coating process generates tiny droplets, resulting in higher surface roughness. To minimize surface microconvexities, the substrate is ground and polished to reduce surface roughness from 80 nm to less than 20 nm. This ensures the lubrication system reaches the required lifespan.

The HauzerFlexicoat 1200 device is particularly well-suited for coating components with high working temperatures and loading densities. The system’s advanced technology allows for the production of coatings with high wear resistance and friction-reducing properties.

Wear Resistance and Friction Performance

The coatings’ wear resistance and friction performance have been studied and analyzed under different lubrication conditions. Tests were conducted at room temperature and high temperatures using a UMT3 friction counter and at the University of Leeds using a modified internal friction gauge in Biceri.

The results show that the coatings exhibit excellent wear resistance and friction-reducing properties, even under challenging conditions. The tests at room temperature and high temperatures using the UMT3 friction counter demonstrated that the coatings outperformed traditional DLC coatings.

Lubrication and Anti-Wear Properties

In addition to wear resistance, the coatings also demonstrated excellent lubrication properties. The tests at the University of Leeds using a modified internal friction gauge in Biceri showed that the coatings reduced friction by up to 30% compared to traditional DLC coatings. The results also demonstrate improved anti-wear properties, with the coatings exhibiting up to 50% reduction in wear rates.

Conclusion

The HAUZERFLEXICOAT 1200 device and TA-C configuration have revolutionized coating technology, offering a game-changing solution for the automotive industry. The advanced coatings demonstrated in this study have the potential to significantly reduce friction and improve wear protection, leading to reduced CO2 emissions and improved fuel efficiency.

As the world continues to grapple with the challenges of climate change, innovative solutions like those offered by Hauzer are critical to meeting future challenges. The HAUZERFLEXICOAT 1200 device and TA-C configuration are set to play a key role in the development of sustainable solutions for the automotive industry, paving the way for a more sustainable future.