The Rapid Development of CNC Vertical Composite Grinding Machines: Trends, Challenges, and Opportunities

The CNC vertical composite grinding machine has emerged as a crucial machine tool in modern manufacturing, offering unparalleled precision, efficiency, and cost-effectiveness. In recent years, China has witnessed a remarkable growth in the production of these machine tools, with a significant increase in the number of manufacturers and products. This article will delve into the trends, challenges, and opportunities in the development of CNC vertical composite grinding machines, providing insights for both manufacturers and users.

Trends in the Development of CNC Vertical Composite Grinding Machines

- Specifications will develop in size and scope: As user demands increase, the specifications of vertical composite grinders will continue to evolve, with diameters ranging from 2.5 to 5 meters. While small machine tools will be limited by market factors, there is still a potential market demand for small-scale machines that can replace traditional horizontal cylindrical grinders.

- Diversification of composition methods: Composite treatment methods will become more diversified, incorporating advanced components and technologies.

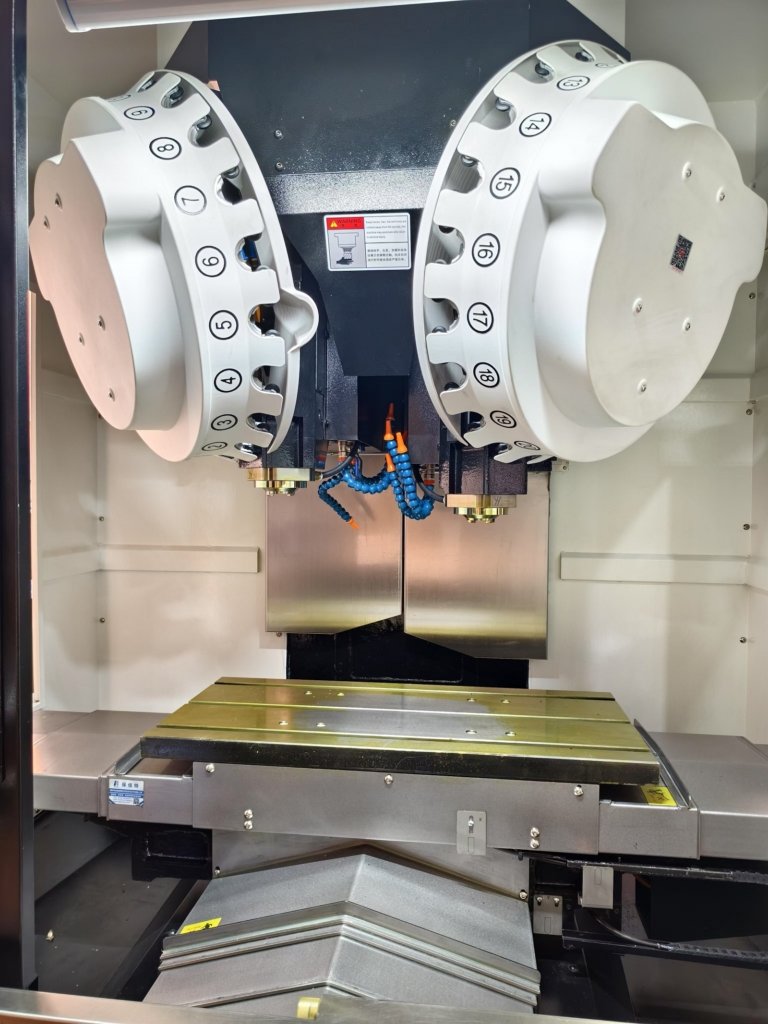

- Integration with grinding centers and machining centers: CNC vertical composite grinding machines will be designed to integrate with advanced components, such as wheel exchange devices, tool exchange devices, and robotics, to form a single, high-integration machine.

- Increased focus on wind turbine applications: China’s wind energy resources hold vast potential, with wind turbines requiring large bearings and components that can be processed using CNC vertical composite grinding machines. As the demand for wind energy grows, these machine tools will play a crucial role.

Challenges and Opportunities

- Manufacturers must avoid rushing to market: With the rise in the number of manufacturers, there is a risk of oversupply and waste of resources. Manufacturers must prioritize quality and efficiency over quantity to ensure success.

- Configurations must align with user needs: Machine tool configurations must be tailored to actual user needs, not solely based on sales considerations.

- Industry standards must be established: As the industry grows, standardized standards and regulations will be essential to ensure the quality and reliability of CNC vertical composite grinding machines.

Industry Recommendations

- Formulate industry standards: Establish clear standards for the production and testing of CNC vertical composite grinding machines, ensuring consistency and quality.

- Promote communication among manufacturers: Industry associations and organizations should host experience exchange meetings to facilitate knowledge sharing and collaboration among manufacturers.

- Develop small vertical composite grinding machines: While small machines may not be in high demand, there is still a potential market for small-scale machines that can meet user expectations in terms of precision, efficiency, and price.

Conclusion

The development of CNC vertical composite grinding machines is a rapidly evolving landscape, with exciting trends, challenges, and opportunities. As the industry continues to adapt to changing user demands and technological advancements, it is crucial for manufacturers to prioritize quality, user needs, and industry standards. By doing so, the future of CNC vertical composite grinding machines will be bright, with immense potential for growth and innovation.