As we all know, the boring treatment of machining centers is more difficult than boring tricks. Why do you say it? During the machining of the machining center, the tool turns and the diameter can only be adjusted by the mechanism of adjusting the boredom tool itself. discharge during the treatment of the boring tool. Let us discuss the fine bore tool used in the machining centers together.

1. Adjustment precision of the fine work -study tool

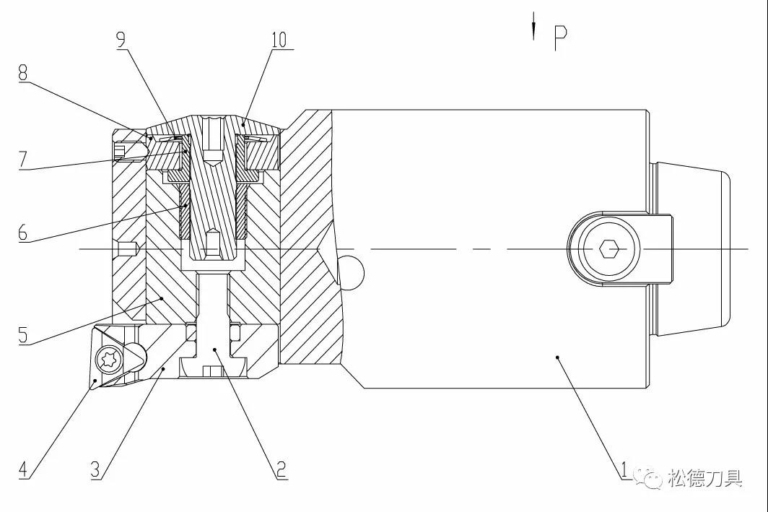

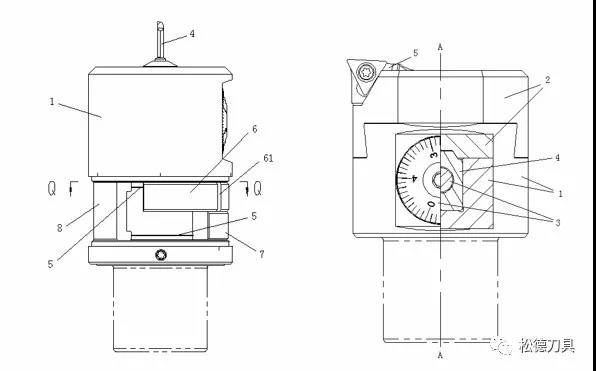

Most of the adjustment mechanisms of fine bore tools used in large quantities on the market are completed by threads of threads, and the precision of the wire directly affects the accuracy of the tip of the tool (organization Songde patent Figure 1).

Institution of patents probe Figure 1

The adjustment of the fine bore tool is determined by the coordination between the inner wire 6 and the external wire 10. The more the adjustment deviation is close to zero, the precise the adjustment accuracy. However, in order to ensure that the position of the point of the tool does not change once the locking screw 11 is secured, the correspondence tolerance between the sliding tool clip 5 and the body of the tool of the tool 1 must be checked at the micron (Songde patent structure Figure 2)

Institution of patents probe Figure 2

When adjusting the diameter of the bore tool, the two points above completely determine if the movement of the tip of the tool can be consistent with the value of the dial. This technology also directly reflects the technical production capabilities of manufacturers of modular fine alcohols.

coward

Of

Boring

knife

Fine-tuning Fine Boring Tool Series Songde

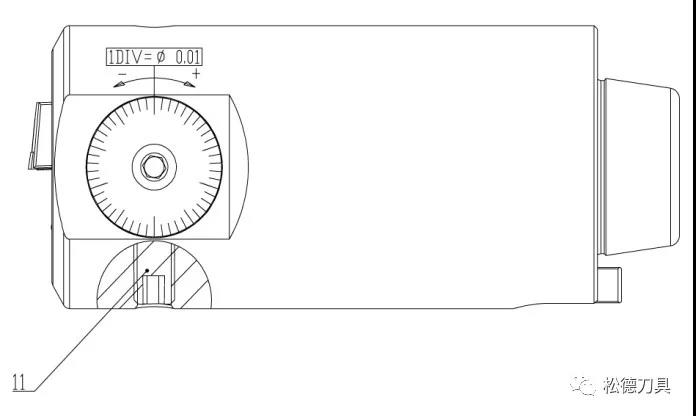

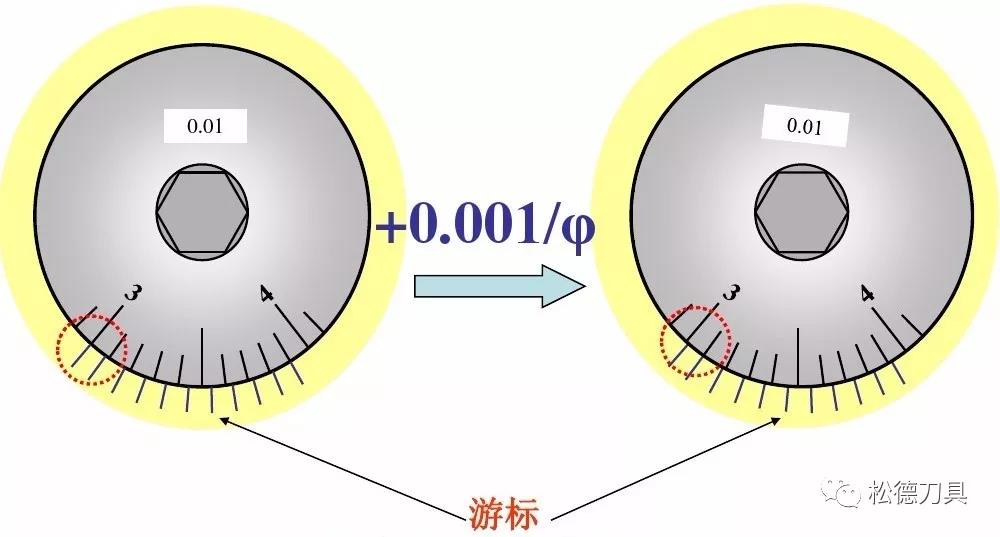

The accuracy of the adjustment of the end of the Songe ending tool is φ0.01 mm / grid.

Figure 3

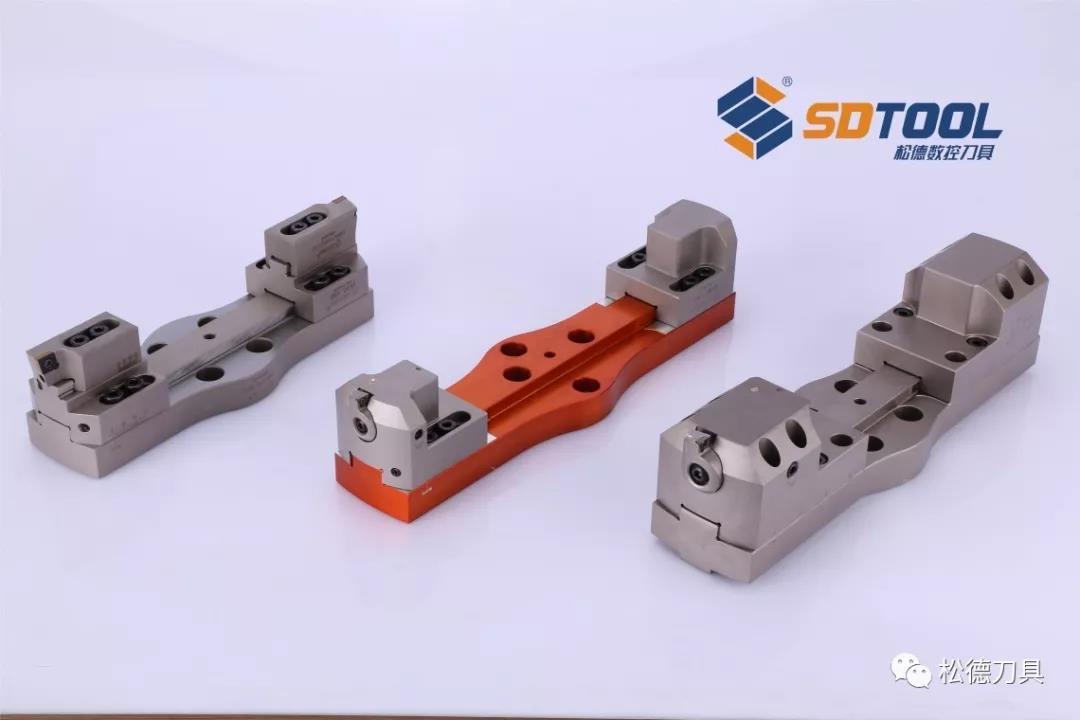

There are several types of finely fine songed disturbance tools: fine boredom tools to a small hole, end -to -end infusion tools and reducing fine boredom tools.

NBF and CBF Small Opening refine a fine bore tool

1

The boredom beach is φ2-φ50, and there are two specifications D02-22 and D06-50. Small end -to -size encouragement tools can be used to process holes with different requirements by selecting different stems of fine breakthrough.

NBF and CBF on a single board function of perception tool

2

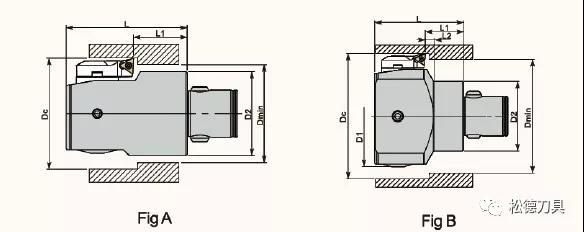

The encouragement beach is φ20 -φ212, the fine NBF improvement tool is an E, and the fine CBF drilling tool is a K interface. The tool support, the long stem and the narrowing rod of a final bore tool are universal for rough work -study tools with the same interface specifications. Each fine bore tool set to each specification has three adapted fine boredom clips: type A, type B and type C to extend its boring beach. But in general, we recommend that you use type A knife clips. Tool holders of type A, B and C have different blade forms to choose to manage different treatment materials. Tool holders for NBF and Fine Boring Tools are universal.

The fine orifice orifice tool can also reverse the tightening of fine bore tool to obtain an inverted fine bore treatment.

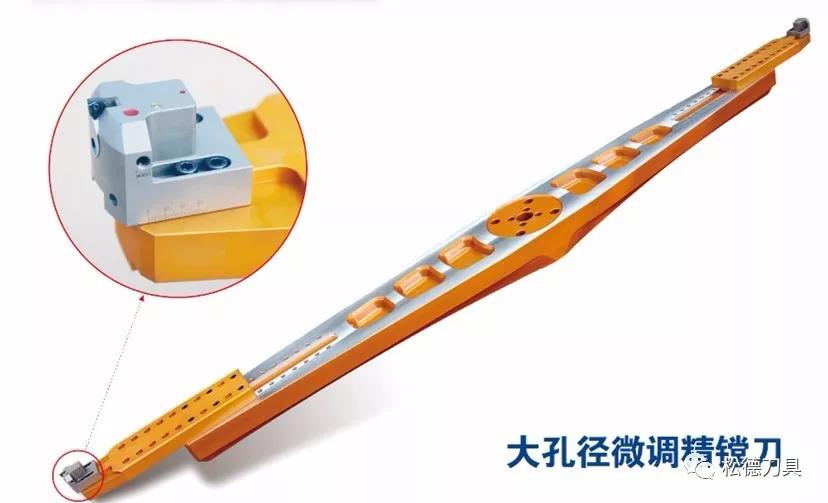

NLF Bridge with a orifice bridge to a fine bore tool

3

The bore beach is φ150-Tre4200.

The main handle and the tool bridge of the end of the fine bore of the bridge type with the same machining range are common, and the end of fine adjustment tool with fine adjustment to the fine adjustment is also common .

The infusion tool at the end of a bridge with a single bridge of φ150-φ210 has two interface forms: e-interface and k-interface.

The fine percussion tool for an art with art with art with a single bridge of φ210 -φ850 has two interface forms: SNL and salt, and there are different forms and different lengths of tool holders.

φ850-φ4200 is a fine alciation tool with a high-height bridge. .

2. Issuilibre and self-reduce of the fine bore tool during rotation

When adjusting the machining diameter of the fine disturbance tool, as the numbering turns, the movement of the sliding tool holder causes an imbalance inside the boredom tool (there is Common problems with the eccentric supervision of ordinary boredom tools on the market). However, in the case of a low cutting speed, this unbalanced state will not have much impact on the precision of machining during boredom with a ratio of appearance between 3D-5D. However, when processing the high -speed bore, the treatment dimensions are unstable and the accuracy of the roundness is reduced due to the influence of the centrifugal force. And ensure the precision and roundness of the customer’s treatment holes.

After the release of the self-balanced agitation tool developed by Songde, while adjusting the machining diameter, the internal balancing blocks move in the opposite direction, thus ensuring the overall balance of the D tool ‘Fine boredom. Screws to lock, and there is an internal mechanism of the oblique block is automatically locked to avoid the lag caused by manual locking. This mechanism was used to considerably improve the accuracy of the tool adjustment and the stability of the machining, thus guaranteeing the machining precision requirements and the stability of the parts in high speed cutting conditions.

The above is a brief description of the problems resulting from the treatment of end -to -hand boredom tools in combination with the products of the SongDe tools. The allocation of the bottom hole in the previous process of fine boredom.

In addition, in order to ensure the precision of coordination of the sliding block and the body of the tool of the boredom tool and the body of the tool for a long time, we recommend that the lubrication oil is injected into The boredom tool every three months depending on the maintenance requirements for maintenance requirements for maintenance requirements for maintenance requirements for maintenance requirements The manual of the BORT SONGDE tool to ensure the accuracy of the ‘Boredom tool.

With the development of boring tool technology, Songde Company also improves its technology and successively develops boring tools and boredom tools at the Micron level. Songde Tools also constantly develops innovative products to meet customer needs.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.