The deep hole hole has always been a difficult problem in mechanical treatment and mold. .

1. Analysis of the drawing partly and processes planning

Part drawing analysis

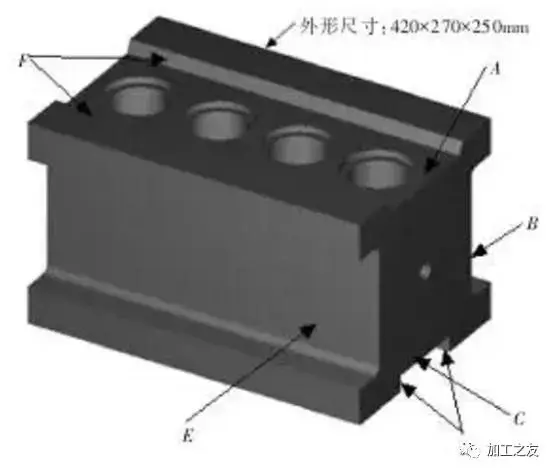

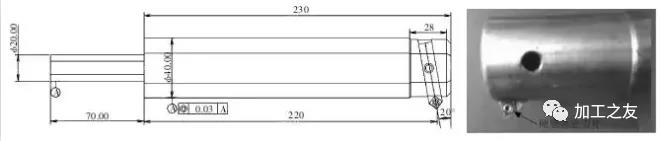

Figure 1 shows the part of the hose mold, with 4 holes with a diameter of 48 × 215 mm to be treated. The external dimensions are 420 × 270 × 250 mm, with 4 grooves on the rod, the bottom, the left and the right, the surface of the hole has steps and the slopes on both sides are the rows of the rows.

Figure 1 pieces of the pipe

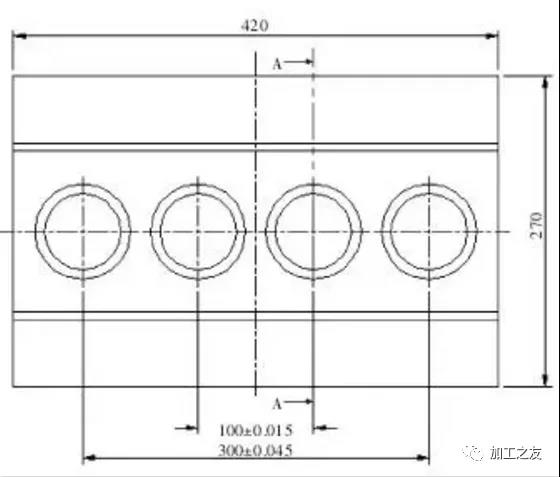

The size of the part is represented in the figure. The vertical is 0.03 mm. Save costs.

At that time, I was not sure such difficult pieces. After many attempts, a simple and reasonable treatment plan has been developed.

Process planning

Simple machining sequence before the ooming of parts

After the return of the fine material, the grinding first treats the grooves on both sides, as shown in Figure 1, the B and E are rough and then refined, and the treatment is reached.

The steps at the front of the treatment are thicker, leaving a margin of 0.5 mm on one side, as shown in Figure 1.

The stages of the lower machining surface are thicker, leaving a margin of 0.5 mm on one side, as shown in Figure 1.

Then reinstall the clamping table, divide the four sides into the center, pierce the center and position it in stages, and treat it with drilling bits with a diameter of 10 mm, 24 mm and 35 mm in diameter. 44 mm.

Once finished, go to the treatment surface and the bottom of the large water grinding, as shown in Figure 2 and grind it to a number, ensuring that the parallelism is 0.03 mm.

As shown in Figure 1, the 0.3 mm finishing allowance is reserved for the lateral grinding of B and E.

Partial tightening and positioning reference

The room is directly tight on the CNC Workbench and the 4 mold pins are coded closely.

2. CNC machining of the parts

Part drawing analysis

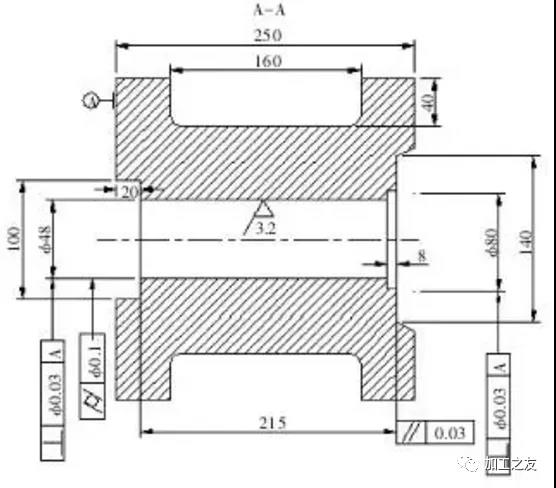

Self-fabricated work-study tool: first make a boring tool holder as shown in Figure 3. The material is 837 hours, runs about first, reserve a 0.5 mm margin and use a grinder. external cylindrical to treat it. The knife support inserted into blade is purchased with standard parts of 10 × 10 mm, which is easy to replace the blade and ensure the size.

The tilt angle of the interior knife support is 20 ° and the thread cut is treated, and is slightly closely adapted. The drilling bore tool support with hexagon screws M6mm and lock the tool holder with hexagonal screws. The standard knife support is equipped with a carbide blade with a main deviation angle of 30 °, an angle of air avoidance of 15 ° of the rear blade and a net angle of the blade with an angle of R0.3 ~ R0.4 mm, minimize the contact surface to avoid vibrations.

Figure 2 Dimensions of the parts

Confirmation of the treatment plan

Treatment diagram 1

The rapid thread cutting process is the most direct and simplest method, and it is not necessary to open thicker. It is easy to break the wire and the surface roughness value does not meet the requirements.

Treatment diagram 2

The slow thread treatment is used because the depth of the hole is easy to break the wires, but the treatment costs for each hole are about 1,945 yuan. calculation.

Treatment diagram 3

CNC Form Milling Treatment, use elongating knives to load the runden cutting or diamond ally cutters and the treatment in deep layers due to the large contact zone, the sound is very strong and hard during each process of power and retraction, and the roughness of the surface produced is the duration The value and the dimensional precision are very mediocre, and there is from time to time the reversed grooves in the middle.

Treatment diagram 4

CNC Boring Processing, the machine model is 850b, which is suitable for general machine tools. And processing time is a total of each hole. By comparing the cost, treatment accuracy and processing difficulty, the solution for treatment for solution 4 is selected.

CNC Boring Processing Process

Clip correction

For machine tools on the room, the 4-cork position is tightened, and the parallel position and the horizontality of the part are leveled. Be difficult to ensure the perpendicular of the hole. The calibration tolerance is controlled at less than 0.02 mm and the four sides are divided into four sides.

Display holder

The first rough treatment uses a counter card to measure the size of the boredom insert than the large tool holder. The main deviation angle of the bore insert is 30 °, the surface of the rear tool is 15 ° and the rounded angle of the tip of the tool is R0.3 ~ R0.4 MM, in order to minimize the contact surface and reduce stress to prevent the reverse shock. The surface of the room with the boring point is 0.

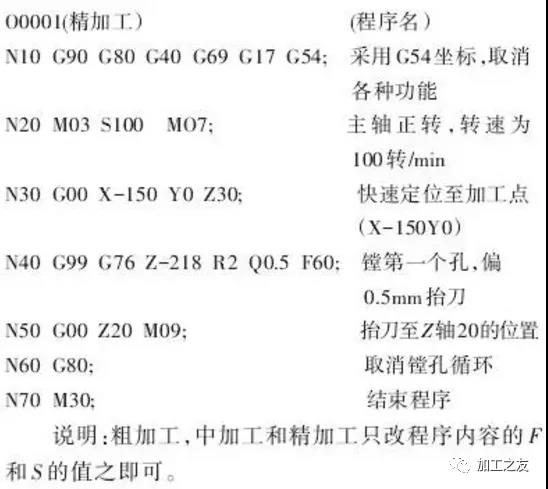

Boring procedure

Instruction format g76x_y_z_r_q_p_f_ ;, G76 is the fine final control, the coordinate position of the X / y / z hole, P is a break at the bottom of the hole, q indicates the break and the shift after the treatment of the tool, so that prevents scratching the machined side when lifting the tool.

Rough treatment parameters

The speed of rotation s is 120 rpm, the power f is 80 mm / min, the cutting volume is 1.0 mm, the cutting oil is the coolant, the fluidity of the Oil should be good and cooling is in place.

Semi-finishing parameters settings

Once the rough treatment is completed, the number of cards and inspection is carried out. F is 70 mm / min and the cut volume is 0.6 mm.

Finishing parameters settings

Each hole is treated with a new blade, with a speed of 100 rpm and 60 mm / min. First try the treatment of holes, because there is a 15 mm stage at the top of the room until the dimensions meet the drawing requirements.

III.

Note: rough treatment, average treatment and finish must only modify the values of F and S of the content of the program.

This set of treatment plans has undergone several improvements on site, starting with the appearance treatment plan. Through treatment, the customer is very that the headache is that the second process machine one day takes to polish a hole and that the roundness of the round hole is not qualified.

Figure 3 Annuyeux

The treatment of boredom is mainly the adjustment of the two power and speed parameters. Min. , and cylindrical and roughness are all the values meet standards, reducing the secondary treatment time of the customer, really improving the efficiency of production and winning the praise of customers.

Although the final boring treatment plan for this set is simple, the process is really not easy. And excessive force will make it too high. Therefore, in the context of treatment parameters such as the selection and precautions of the blades, we hope to play a role in reference and prevention.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.